-

Posts

814 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Scrambler82

-

Alumina Shelf Opinions, pls !

Scrambler82 replied to Scrambler82's topic in Insulation and Refractories

Sent an e-mail asking about the content and questioning the tile being sold under the high alumina title. -

Alumina Shelf Opinions, pls !

Scrambler82 replied to Scrambler82's topic in Insulation and Refractories

I am not sure about this, mainly because I don't know. I saw the High Alumina and thought it would work. Here is the MSD, maybe this will help ! http://www.psh.ca/MSDS/KilnFurnitureDyson.pdf I notice 1200 degrees C... Please post what you think, thanks. -

Alumina Shelf Opinions, pls !

Scrambler82 replied to Scrambler82's topic in Insulation and Refractories

Contacted the Ceramics Store Posted above and asked about custom cut Alumina Shelves. I asked about cutting the following: "3.5" X 13" tile for my back interior wall, 2 - 7.5" X 3.5" tile for my end interior walls, and a 7.5" X 13 tile for my interior floor, these are the wall/floor pieces for a Diamondback 2-Burner Blacksmith Forge", I didn't mention the thickness but they are willing to custom cut those sizes in 3/4", out of a 16 X 16 X 3/4" piece ($56.00 stock piece), for an addition $20.00 ! I can't rent a wet-saw for $20.00 so it is not a bad price. Also, thre was a 18 X 18 X 1/4" for $36.00 (which I can't find again), so now it could gets even cheaper, $56.00 plus shipping; I haven't asked about shipping ! If someone can't find a local supply for their Alumina Tile, this could be a good alternative location, sized for their use, buy it, get it, slip it in ! –------------------------------------ Additional Info: Here is where I sent the cutting question: euclids.com, but I got. Response from "The Pottery Supply House" ! I will have to check this out first ! Shipping would be $12.50 for most orders, larger order will be addressed as needed. They are located in ON, Canada -

Alumina Shelf Opinions, pls !

Scrambler82 replied to Scrambler82's topic in Insulation and Refractories

Contacted the Ceramics Store Posted above and asked about custom cut Alumina Shelves. I asked about cutting the following: "3.5" X 13" tile my back wall, 2 - 7.5" X 3.5" tile my end walls, and a 7.5" X 13 tile for my floor, these are the wall/floor pieces for a Diamondback 2-Burner Blacksmith Forge", I didn't mention the thickness but they are willing to custom cut those sizes in 3/4", out of a 16 X 16 X 3/4" piece ($56.00 stock piece), for an addition $20.00 ! I can't rent a wet-saw for $20.00 so it is not a bad price. Also, their 18 X 18 X 1/4" is only $36.00, so now it gets even cheaper, $56.00 plus cutting and shipping; I haven't asked about shipping ! If someone can't find a local supply for their Alumina Tile, this could be a good alternative location, sized for their use, buy it, get it, slip it in ! -

Alumina Shelf Opinions, pls !

Scrambler82 replied to Scrambler82's topic in Insulation and Refractories

Yes I did, not thinking about the walls of the forge though. Tell me... How would you adhere the 1/4" sections to the walls of the forge ? I like that idea, will have to keep it in mind. Just looked it up the measurement for the Diamondback Forge are: Interior: 13.5" L X 7 1/8" W X 3.5" H, there has to be something there I can mod to fit ! Thanks ---------------- Mikey, Please tell me again about the Alumina Shelf Material, i.e. 3/4" thick, being used as a floor, I just don't get it, why won't it work as a floor on a box type gas forge ? Maybe over a good insulating solid material ? If I use the Alumina Tile, on the interior walls, it is still necessary to use the Metrikokte ? I was under the impression that the Metrikote should be used no matter what material is already in place. One more question, from what I have read about the DB Forge's insulating material, it calls out a dense ceramic floor, is anything needed on it, replacing it, or just something under it to add to insulation ? ( Is that more than one question ? LoL !) Thanks for your time and the effort you put in this Site ! -

Alumina Shelf Opinions, pls !

Scrambler82 replied to Scrambler82's topic in Insulation and Refractories

Thanks for the response ! (That’s one thought !) -

Alumina Shelf Opinions, pls !

Scrambler82 replied to Scrambler82's topic in Insulation and Refractories

Frosty, I have the bad habit of writing about two things at once, my mind says I am doing it correctly but the understanding of the reader is another thing ! My Lit Professor in College always said I was writing two books at once, I think it is more like three or four, but he said my thought patterns are working double time and I needed to get them straightened out so people could understand what I meant to say, that is the real reason for my messed up ideas. (ADD / OCD) To straighten this out some, my first intent of this thread was to determine if the Alumina Shelf in the attached picture above was a good quality, then I wanted to get an opinion on whether or not it would work as an insulating plate under my forge, sounds good so far, somewhere in between my mind told me if I used the ¼” shelf as a floor in my forge, mainly under the burners I would make the floor last longer and it all got mixed up. Mikey answered the floor thought, Thomas came in reading the first idea and commented on the intent of the thread based on the… as you can see the longer I write the more confused I get ! Now just to clarify… I got most of my thought from reading too much, read one thread you get a thought, read another thread and a bubble breaks in the old brain and you put two and two together and you get another BRIGHT idea ! So…, from all of these good ideas mentioned above, which I appreciate because how can my mind work overtime without more than one idea going on at the same time, but what I am carrying away from this thread is, the Alumina mentioned above is an ok product and would work for the interior of the Forge but it is not suggested to be used on a flat bottomed forge like mine; it would be a better idea to use the Kast-o-lite -30 as a bottom plate. Also, Fire Brick, Steel Pale with air space and the idea I liked the best is yours, the Cement Backer Board, used with spacers will stop a lot of the heat from the bottom of the forge transferring towards the second shelf and towards the propane tank area. OK, in my mind we are all set but I hope this straightens it out… on to another thought ! Frosty, when/if I form up the Kast-o-lite -30, what would be the best material to use as a form, thinking about sticking ? Can it be cut after hardening ? The floor of my forge is approximately 7.5” x 11”, thats off the top of my head, should I make the casting larger than needed and cut it for a tight fit or does it really matter. One of the good points of the Diamondback Blacksmith Forge is the front and top can be opened up, allowing easier insulation relining. Looking at the existing insulation, they are loose fitting, looser than I would have expected but still wonder about the loose fitment of the existing insulation. Sorry for carrying on, I get carried away thinking of all of the things I still need to do. Thanks for asking, hope this post doesn’t add to anyone confusion other than mine. GrevB -

Alumina Shelf Opinions, pls !

Scrambler82 replied to Scrambler82's topic in Insulation and Refractories

Ok then, either a piece of steel or maybe even fire brick; I'll have to see what I can find. My time frame for using the Forge will be small in comparison to someone making blades, but I don't want to take the stand apart after it is assembled. I know you don't always get it right the first time but that's one of the reasons I ask too many questions and it take far longer than most to build something, it is called "DIRTFT", "Do It Right The First Time" ! Mikey, this castable product you mentioned from Wayne, can you make a form and cast it ? The DB Forge can be opened completely up allowing retangular piece to be slid in place. Thanks for the input. Now that is a great idea, easy to come by too. Thanks Frosty -

Alumina Shelf Opinions, pls !

Scrambler82 replied to Scrambler82's topic in Insulation and Refractories

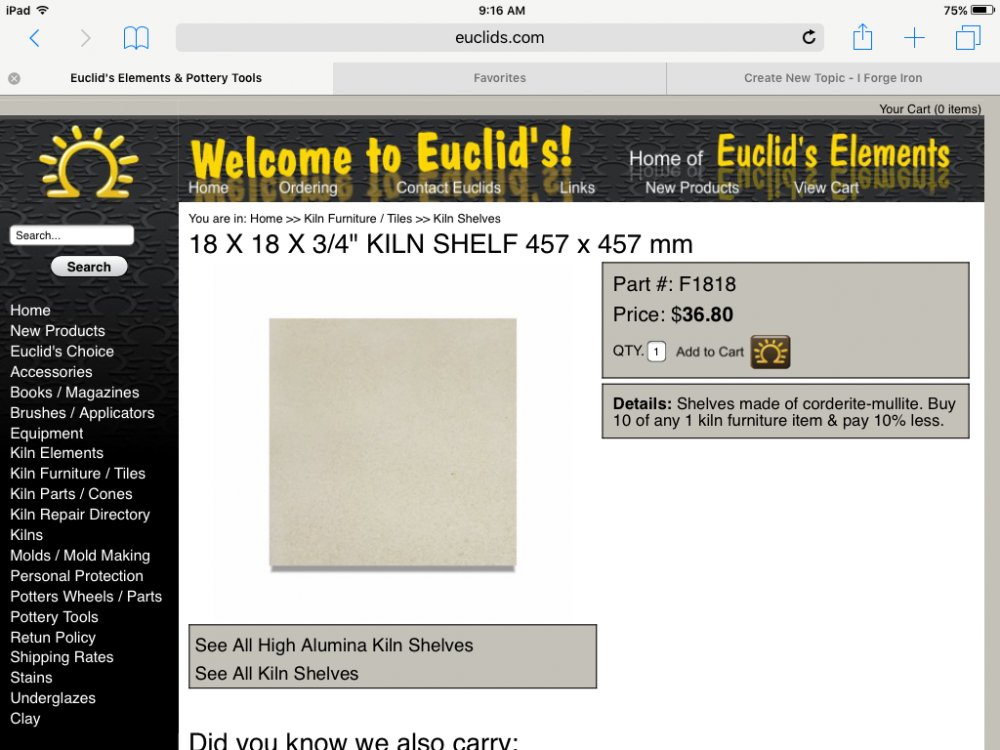

I posted a picture of the Site Page and I guess it didn't show ! Here you go ! Thks for the input. The 18" X18" piece was going outside, under the Forge to reflect heat away from the lower shelves, but I was thinking a 1/4" thick piece for the floor inside too. It would have been large enough to cover almost all of the floor but mainly I was thinking under the burners. Thks Thomas -

I wanted to put an insulating layer under my Diamondback Forge while I am building the stand, was thinking Fire Bricks then I found an "On-Line Store for High Alumina Shelving" and thought the price was on the low side so wondered if there is more too it than I know about ! A piece 18x18x3/4" is $36, again I thought the price was good. I haven't looked locally for Kiln Shelving or for standard fire brink but just wanted options on the product. I was also thinking the 1/4" Shelf might make a good floor for the forge as time goes on, washed with Mertikote (spl). Opinions please/thanks ?

-

Funny thing, almost all of the brass nipples/pipes are made in China, even when you get some that is really nice, fits well, then you find out it is made there too ! I was talking to the Ace Hardware Plumbing Assistant, he told me all of the brass pipes in the store are from China. I asked about the quality and his response was that he had no returns and there nipples/Pipe is really nice stuff ! I found a On-Line Plumbing Site selling China Nipples, I ordered a few to see, they are covering the shipping one way, if they are as good as the Ace Brand then this may be my new supplier for Brass Piping/Fittings ! Why do I need more brass piping, I make Wine Bottle Lights and use brass piping. The one I am working on now will have eight of the SoCal Local Winery Bottles, Blue and Amber Bottle Colors, arranged off set and I am trying a Chandelier this time. p.s. The Wine Bottle Light thing is one of the things I will be trying to do using hot steel, wrap the bottle with some vines and grape leaves; hoping for the best on this one.

-

Thanks for all the assists ! I used the yellow thread tape, marked for propane use, wrapped easily and appears to hold position well ! My tightening methods are a little off but I will learn ! I will use the "TTT" method of tightening, tighten, test, and relighted if necessary !

-

Thanks, never thought of that !

-

Sorry for your disappointment, the main thing is to try and stay ahead of the curve even though people may think you are behind it. Yes there is a lot of info and videos on the web, too much maybe. It is funny that a lot of the info suggests use of a thread dope type sealant, not the tape and in a lot of the answer forums no one can agree to a correct method, some say the say thing but a little different. Anyway, thanks for responding, if I get too many leaks I will take it apart and use a thread dope !

-

Frosty, I like asking questions just to see the answers given and sometimes to bring awareness to a thread or site forum where the same question is never asked but maybe should be. No head slapping on this end !

-

You are saying to spray water on the walls of the forge before applying the Metrikote ? If so I am glad i re-read the thread. I need to order the Metrikote, been putting it off too long.

-

Thanks to all !

-

So after reading this and other things AND always have thought that the Tape was more of a lube than sealer, I am still confused. I also always thought Pipe Dope, was more of a sealant than the tape ! I too, as stated, use two layers of stretched Tape, seemed to have always worked. Who is really going to count either the number of threads or the number of turns after seating the fitting... I don't, I am more a feel kind of guy ! I guess I will keep doing the tighten, test, tighten more if necessary procedure, I will call it the "TTT Procedure" !

-

That was my thought too and I believe the paste seals better with less hassle ! I also found out a little trick in applying the tape, no one told me, it was like a light dawned on Marblehead, (Northeast MA joke), if you apply the tape too low it overlaps the threaded portion, allowing the excess,to come off and block all kinds of stuff, if you keep the tape back one thread it will work flawlessly... What a good boy am I ! I have been doing it wrong for a long time and just got it while putting tape on the propane piping system. The next two questions are... 1) Hour much Thread Tape should you apply for the proper seal ? I use two wraps. 2) How do you determine the proper tightness for a fitting ? My present method is tighten, test for,leaks, tighten again if necessary !

-

During all of the rig-a-marole... of brass fittings and piping, I have come away with two things, don't order fittings on-line unless you know what you are going to get AND the biggy... drum roll... Propane requires a different Thread Tape ! The question is, "What is the difference in Thread Tape, Propane vs Regular Thread Tape vs what ever else is out there" ? I have used regular Thread Tape for a long time, I admit, never on Propane fitting but only because I have never assemblies anything requiring Propane, so I was and still am a little ignorant to the differences. I do know sometimes regular thread tape doesn't work well. Can this special Propane Tape be used on regular threaded fitting used in other applications, i.e. Water, diesel, gasoline, etc, etc ? So many questions for an old guy, I think this is something that should have come up earlier in like, lol ! ltr

-

Believe it or not here in SoCal I found that the Brass Fittings and Brass Pipe is comparable with iron pipe, in fact there was a store where the brass product was less money, go figure ! Ace Hdw Store had brass fittings for the same or less than iron. Someone else had mentioned the price before this, so I compared them and since I already had some of the brass it was less expensive to go with brass and then Ace got in on the deal and it was even less money. Also, the first picture I saw of a hard piped propane supply system on this site was brass, it looked great, professionally put together. If I had started from scratch, maybe I would have gone the iron pipe route but it is what it is... done ! And... something learned, the Thread Tape used in a propane hard piped system is not the same as standard Thread Tape, don't ask what the difference is except it is light yellow in color. I have only read one post that mentioned a different Thread Tape, didn't know for sure if it was true, I mentioned it to the Ace Plumbing Clerk and he immediately said "yes there is" and pointed it out to me. Is it really necessary to use a special Thread Tape for propane fittings ?

-

Why BRASS . I had some, got caught up in ordering some new stuff, but recovered. Purchased any new fittings I needed, found a place to get a few long pieces of pipe. I purchased two needle valves, they are brass, seemed ok ok to just use brass. And last but not least, it looks good ! Auto Parts Store. Have miscellaneous 1/8" stuff more than the larger sizes, and most fittings used on car/trucks are steel. Brakes need steel not brass, steel tubing not copper, S/S is good too. The overall thing that bothered me is the non-exsistance of longer pieces of brass pipe/nipples, I guess home owners just don't use this stuff the way I would.

-

Thks, I will be trying a local Irrigation Supply House today, most Plumbing Stores tend to not carry a lot of brass pipe/long nipples. After tha my pipe trek will take me to my Propane Dealer... I always tend to make thing more difficult ! Lowes and stores like that are ok but you need to watch what you are getting and my local Lowes doesn't like me opening up the packages to try the fitment ! Always something !

-

Morn'n, This isn't a Gas Forge question but is related to Gas Forges in general. Does anyone know of a Supplier for 1/4" Brass Pipe, i.e. Long Nipples ? I am looking for three pieces, maybe five, of 1/4" Pipe, 9", 10", and 17", threaded, MNPT ! There are a few Sites that sell what I am looking for but since my last experience with buying fittings on the web (Walmart.com) I am leery of what I may end up with ! Anyone use a particular supplier ? Thanks up front.

-

Above is the retyped entry, edited in a place or two, that is what it should have said ! Sorry for all the misspelled or incorrect words used, I need to watch this, been using my iPad lately and it is a problem.