-

Posts

177 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Jacob Nothstine

-

-

These are great vise for flipping on ebay. I pick up a Wilton vise last year for $35.00 and sold it for close to $200.00 People collect them and will pay a lot.

I use my machinists vises for holding bending jigs now and then, but a post vise is better for blacksmith work.

-

-

It's been a good month. My sister said she had some square tubing that was left in a house she is sell and asked if I want it? Showed up at my place with a trailer. Drop off 38 ft of 2.5" square tubing 3/16 thick, 16 ft of 2" square tubing. and a 3" round solid bar about 12" long. Was thinking of making a anvil stand not sure if 3/16 is thick enough for the legs, could double it up and make 2.5" x 5" legs.

-

I like Heller and older Plumb brand hammers.

-

I picked up 30 new hammer handles for $15.00 at a sale, but the best fine of the year so far was a scrap yard only 15 minutes away that sell steel for .20 lbs. picked up a 9" steel disk to make a bender out of and some 2" round 1045 for hammers, with all the new handles I will have to start making hammers.

-

You might want to check out Kingspor's they sell belts in variety packs and leather belts. I have not tried the leather belt yet but a friend says they are great for re-sharpening tools.

I have used my Kalamazoo 1 x 42 for sharpening tools and it works great. Taking large amounts of material off, it's a slow go.

-

I like it, something different, made me smile.

Was also thinking a fish hawk would be cool.

-

Finished my winter lathe project. Back in July 2014 I picked up a Craftsman Lathe at a garage sale for $25.00 I cleaned it up and built a stand for it. To power the lathe I put a Baldor 1.8 hp 3200 rpm DC motor with a MC-60 variable speed controller . I can cut the RPM in half with the original pulley system and drop the speed to a crawl with the variable speed unit. I also found an original compound tool rest and 3 jaw chuck for turning metal. I just added a variable height dust collection system to it. The collector can be remove and move down for longer turns. I'm still testing it out but it's been a lot of fun. Project kind of back fire on me, ask my son if he wanted to forge the other day, "no I want to turn on the lathe" he likes making tops.

-

-

Let it snow, I was just given a Snowblower (we have had no snow since I have got it ). I put new paddles on it and need to use it once, before I have to store it the rest of the year.

-

Nice looking RR Spike Knife, my son has made a few hooks will have to see if he wants to try one.

Forge welding, I just pick up some Irionmountain flux for my gas forge and been happy with the results.

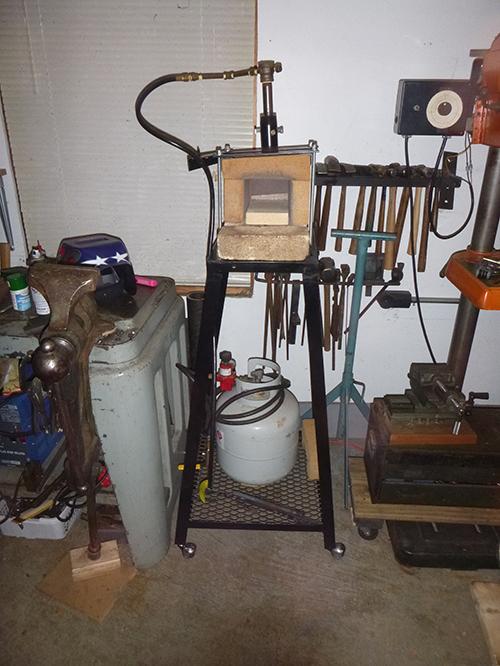

For the bottom of my forge I have a 2900 F Super Duty Firebrick it helps protect the bottom of the forge.

-

Looks great, like all the extra room you have on the cart.

-

Would a Black and Decker workmate work? Take the wood top off and replace it with 2 piece of angle iron. Clamp your forge in the middle sideways so nothing is under it. They fold up and are cheap used. I was thinking of making one into a welding table. Replacing the wood with steel plate.

-

-

I had a Chop Saw but never used it between the noise, dust and sparks. Would take it outside. The band saw is great for me I can cut metal when the kids are in bed sleeping. Don't have to worry about setting the garage on fire. The band saw does take a little more practice and tuning to get good results. You have to adjust it when going from tubing to solid stock. I pick mine up for $100.00 used and abused.

-

This CL anvil started out at $130.00 and has been going down in price slowly,

But it's gold plated and custom made for a blacksmith named Dave. If only it said Jacob :D

-

If the 1" round was high carbon steel and you quenchant it in water, it could become brittle and can crack or break. I have made this mistake a few times.

You can do a spark test to get an idea if it's high carbon. search high carbon steel spark test online. It would also be a pain to weld.

-

Here is a video a friend sent me the other day of a brace made from re-bar. Not sure if re-bar would be a good material. But might help with design ideas.

-

8 dirty horseshoes and a welding jacket

Just what I wanted

-

Great looking tool rack.

-

-

Making a Cyclekart with my son, it uses motorcycle wheels. Had to take a motorcycle tire off the rim so I could drill mounting holes. Didn't have the special spoon tool for removing the tire. So I used a holdfast. Normally used for holding metal down on the anvil. It worked great. I also used my post vise to hold the tire. Going to make a couple spoon tool before I put it back on.

-

In Michigan DTE Energy will pay you $50.00 for old refrigerators. I think that's 1 bag of coal or 2 LP refills for me.

-

My ax, hammer, tomahawk drift came in the mail today from Iron Mountain Forge. Hope to give it a try tomorrow.

inexpensive MIG welder advice

in Welding/Fab General Discussion

Posted

I picked up a HF 90 amp flux welder for $60.00 used on CL. They work fair, you get what you pay for. The trick is to replace the wire and tips with Lincoln brand . The wire that comes with the HF welder is pure junk. It would make a good weld but being a flux welder it was smokey and would leave flux and slag on everything.

I did replaced it this winter with a Eastwood 135 mig welder with gas. Need to do some body work this spring, it's a lot nicer welder but everything out the door on sale with full tank was around $400.00 I did have a Lincoln 140 a long time ago it was a great welder but cost a lot more, I ended up selling it with my 65 Mustang.

I was able to sell the flux for $65.00 on CL.