eseemann

-

Posts

967 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by eseemann

-

-

I work as a DoD Contractor in cybersecurity everyone + dog is always trying to show just how smart and indispensable they are. I love when someone can simply say "something to make it blue" without feeling the need to go in to detail.

-

On 6/6/2020 at 1:20 AM, D.Rotblatt said:

Flux? 20 mile team borax at your market in the laundry section.

D, I have not been able to find Borax at Walmart of Kroger in Huntsville Al. I don't figure there is a big pandemic panic buying or Borax so I wonder if they pulled it from the store.

-

On 4/7/2019 at 8:32 PM, Frosty said:

borax, boric acid and something to make it blue.

I wish the rest of my world was as straightforward as Frosty.

-

I had one of the electric units from Cast Masters and something was not right in the thermostat since it is rated to 2000 and went over 2400. I contacted them via Amazon and they are sending me the stainless steel version of what you have. Did you coat the Kaowool with anything? I am looking at all that uncoated wool and it makes me nervous.

On 4/8/2019 at 11:11 AM, John in Oly, WA said:I'd get the next size smaller crucible

John, I guess I need to take the same advice since I want to coat the Kaowool in the foundry they are sending me but all I have to work with on hand is kast-o-lite 26 li plus or Mizzou Castable Plus. Looking at how snug the crucible is stilling I am betting I don't have space for even a 1/2 inch coating. How much room would you say you need for air and gas movement around the crucible.

-

On 2/7/2020 at 4:43 PM, bluerooster said:

In my improvised anvil I would like a hardy hole. What would be the easiest way to do that in a 4x8x12 chunk of steel, with limited tools?

I had thought about welding a piece of square tube to the side, and offset my hardies to sit on the face. Will that work?

I would look for a RR tie plate at the scrap yards. Another option would be looking for a scraper blade like one in this photo. I found it at my local (almost) scrap yard in Park City TN. From what I have read it is AS500 steel and hard as the dickens to cut. Once I managed to get it cut I welded it on to some I-beam sections as striker anvils.

The MAJOR down side is I can't see AS500 wanting to weld to other types of steel w/o a fight. That is the good part about the RR tie plate, that should be easier to weld.

On 2/7/2020 at 7:30 PM, Goundry Forge said:The below link might give you some ideas.

I agree that is something worth looking in to. If nothing else that would be a great work surface.

-

Mr. Thomas,

I am doing what "read this first" tells you to do, look at the older posts. This is just the information I needed. I have some old (very well used) steel from a field cultivator that I was thinking about using and wondering if forge welds would help and metal fatigue.

Thanks for the info.

-

On 6/25/2009 at 10:17 PM, John Martin said:

I swear by my diamondbackironworks forge. It's a two burner knifemaker. Forge at around 4psi, and weld at 6-7psi. It should be your last forge that you will ever need. However, I have never used a chileforge, so I have nothing good or bad to say about them other than that a lot of people who have one like it.

Are you using the 2 Burner Knifemaker/Welding Forge? The website says it uses Ceramic Hardboard, does that mean it has the stuff to keep loose fibers from messing up all the hard work stopping smoking? The reason I ask is I have never understood the deltas between ceramic hardboard or ceramic wool.

-

This is not about a propane tank on a forge but on a gas grill. I was all hot to trot to do me some grilling Friday night! My most wonderful Bride of 22 years had outpatient surgery on Valentines day and I wanted to make it better with a nice meal. So I came back from the store with shrimp, salmon, mushrooms and little sweet peppers to put on the grill.

I had not stopped to think about the fact that is was 23 degrees the night before, the dog water was still frozen and the grill tank had no sun on it do to being under the grill cover.

Needless to say there was no grilling in the Seemann House that night. Yup, it was a rookie IFI miscalculation.

Yesterday I left the tank in the sun until 2 pm and we had a mixed grill dinner that could not be beat.

My wife is doing well but I hate that it had to happen on Valentines day.

Take care all.,

-

I thought that would be a neat side note. Looking forward to seeing it work.

-

That build is looking great. This is very random but you mentioned the woodpecker motif back on 7 Oct and that got me thinking back to a small hammer bench top hammer I saw on Youtube. This thing was like a sewing machine with a 10# or 15# needle. I had just competed some of the Allan Quatermain books and one of the main characters was a Umslopogaas, a Zulu Chief who for no fault of his own needed to take his act on the road. Umslopogaas used his axe, Inkosi-kaas, to peck at his enemy like the Picador with his lance or the Banderilleros with their darts during a bullfight. This style of getting stuck over and over. That how Umslopogaas got his name of 'Woodpecker' that according to the author translates to "woodpecker" in Zulu.

-

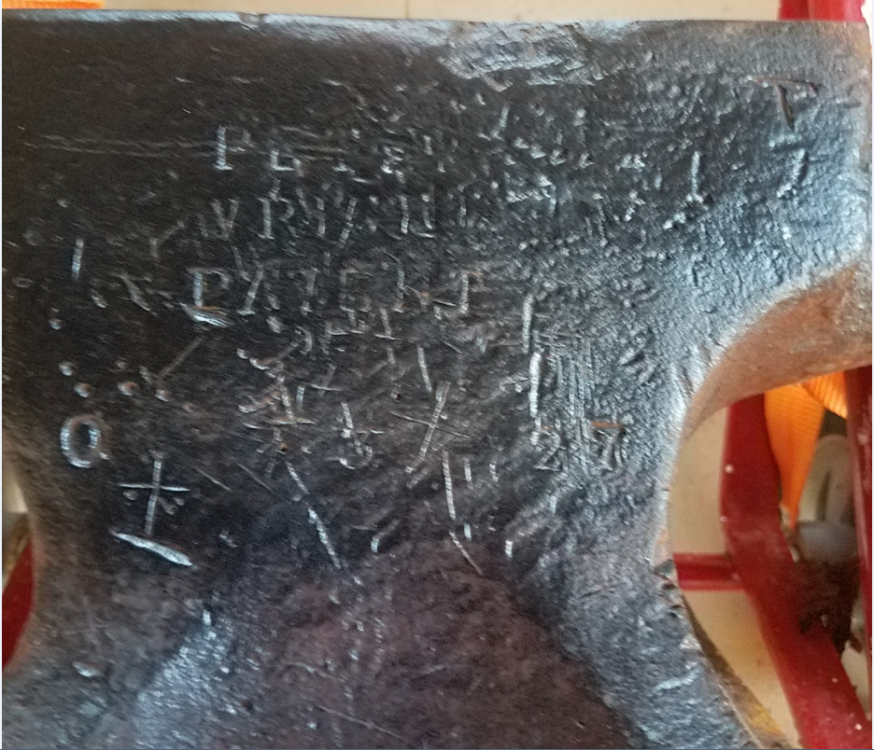

The guy I got it from did say he milled the top flat. I think the ladder pattern is due to the mill he used. The top is very flat and smooth. I would not be at all surprised to find out the top looked like Harag the Horrible's sword in some places. It is a new to me that is heavy and has a much better rebound than my home built job.

5 hours ago, ThomasPowers said:I've also heard that they used to impress a customer that way back in the day; most folks not knowing that the body would be dead soft wrought iron and it's only the face that is hardened.

That one is fairly lightly marked up.

Looks like the cutting plate was heavily used and ground down to hide that.

It was a tool, the smiths at that time were not worried about the resale price in the 21st century.

-

Good Morning All,

I was on vacation and I found a long time machinist with a very nice anvil for only $300.00 so I took him up on his offer. The nice part about getting the anvil from this guy was he had a racquetball sized ball bearing to test the rebound (around 10 inches out of 12 inches) and he refaced the top so it is as smooth as glass.

I have seen a great number of anvils that have dents in the slid like this one has and I wonder why people seem to beat on the non-working part of the anvil.

-

This item is about 3 inches but I have been able to weld up something that may work even better. I will up load a photo when I get done.

Thanks for everyone's input.

-

That is what I am thinking as well.

-

Daswulf,

I don't think that is what it is you have given me another idea what I might use.

The attached image is an example of what one guy made with aluminum flat stock. If I can't find anything I will use the one item I have as a template and hope for the best but as you folks know hope is not a plan.

thanks

-

Farmall and Mr. Steve,

I am running these leads down now. I found out the trade name EFCOR is short for ELECTRICAL FITTINGS CORPORATION. I love old companies that have names that mean something.

Makes it easier to run down leads.

-

That is a very good question I did not think of but I don't think so. It sticks to a magnet like glue and I tried to scratch the surface with a snap knife. I am just about sure it is steel. Now that I think about it I have cut these in the past and I do think they are steel.

-

Good Afternoon All,

I am working on making a grabber that will pick up heaver things since at 6' 8" tall the ground it a LONG way down. I got a number of these items from a surplus store many years ago and now think they would be of use in my grabber build. If I knew what to call it I might could find some on the web or at the hardware store. The item is about 3 inches long and the holes are a bit larger than 1/4".

The imprint is EFCOR (the manufacturer) and IBEW. I think IBEW is the International Brotherhood of Electrical Workers.

Before I start looking for the correct hay stack to start looking for this needle I thought I would try my luck with you good folks.

Thanks in advance

-

On 4/23/2019 at 8:05 PM, Frosty said:

The best cure method according to the maker is to treat it just like hydraulic concrete. It water SETS, it does NOT DRY. These are two entirely different things. Read up on working, and curing a patio or shop floor. Portland cement, concrete and Kastolite set and cure very closely to the same in time and steps. Kastolite refers to concrete procedures as THE way to cure Kastolite for maximum strength and temperature rating.

Except for water % details the comparison is across the boards close enough to the same as to be interchangeable.

So, when it sets close it up in a 100% humidity atmosphere for up to 7 days. We do NOT need a max strength cure, we aren't subjecting it to the kinds of forces temps and atmospheric changes a commercial forging or scrap furnace does.

Frosty The Lucky.

Mr. Frosty,

So I have the strangest mental image of one of the walk in humidors at the fancy cigar stores where they have the bulk of "the good stuff". Is that the type of atmosphere you are talking about? My daughter and I are doing the opposite of that right now with a large plastic box, a laptop that had a cup of water spilled on it and two buckets of DampRid. Am I correct that in this case I would use the large plastic box or trash bag, the item to be cured and some type of humidification agent like a large wet sponge in a bucket?

Thinking about the way water chemically bonds to Portland cement so it will set underwater (found that out the hard way back in High School) leads me to guess that a well mixed Kast-O-Lite will do the same thing. My (limited) understanding leads me to guess that water makes a chemical bond to the Kast-O-Lite but to a MUCH higher temp is required to break the bond and cause a explosive spalling.

So once you have your forge or foundry spend the week in the swamp it should (we hope) be cured? How forgiving is Kast-O-Lite if too much water is used?

Thank you for being the resource all of us want to be like when we grow up.

Ernest Seemann

-

23 hours ago, JHCC said:

The question is, was the hay buddin’?

That is a bad pun by my (very low) standards.

3 hours ago, pnut said:The indigenous folks raise them for food in the Andes. Mmm mm. Just kidding I don't know how tasty they are. I like the little critters. They do make a bunch of different noises. I could imagine a herd of them could get a little annoying.

Pnut

A herd of guinea pigs, looking out on the yard and seeing nothing my lumps of furry cuteness, all little squeaky voices and whiskers. There are people that have a fear of mice and such that would extend to guinea pigs but not me. Can you imagine what it would look like driving this herd from one pasture to the next. There is a Far Side comic waiting to happen.

-

Frosty,

You do have a point. Sort of a pulse width modulation type of thing.

-

Where are you going to find 6,000 degree rated firebrick for the firebox? Much better for foundry work if you can work out the brick problem.

-

34 minutes ago, Charles R. Stevens said:

Steel tripods

Tripods seemed to work well enough for the martians in War of the Worlds.

-

Pnut,

That is not a half bad idea. I have seen people talk about concrete but that cracks but your gravel will keep shifting to fill in the voids.

There is a guy I saw on YouTube making a fixed straight razor (as in not folding) and he was using something that looked like a 4 inch wide shaft as his anvil.

Propane forge melting copper

in Smelting, Melting, Foundry, and Casting

Posted

Frosty, it all makes sense when you remember that computer hate us (people) that is the only answer.