andys MQ

-

Posts

59 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by andys MQ

-

-

On 21 April 2016 at 8:22 AM, mattlock said:

The last one is hammer I broke I belive retriveing it. Thank you so much for telling what the hinge is form. The triangle piece is a wrought iron final.

I think you will find he means the hing is called piano hinge rather that referring to its use.

it may be from a piano but more likely from any other hinged thing.

-

Nice work !

How did you get the patina??

-

Sorry guys brass and aluminium do not mix.

copper and aluminium destroy each other. As in aluminium will become an anode for the copper and corrode rapidly, brass is something like 60% copper and as such should not be used together.

If you tried to electro plate it I believe it would not work. If anything happened it would not look great in sure, and defiantly woulnt last.

As was mentioned steel may be a better option for electro plating with brass or copper.

-

Ahh spewing looks like we are going past on Monday the only day they are not open.

course it would happen that way

-

Thanks josh I will look it up

-

Awesome thanks buddy might drop in.

Sorry been busy and didn't get to reply too fast. But much appreciated.

-

Hey ya all just wondering if anyone has any idea of a forge that might have a open day between now and the 19th I'm doing a road trip and was thinking what better to do then drop in to have a look, if anything was happening.

Anyway im are in NYC from Wednesday the 28th to like the 4th then driving down the Mississippi through Nashville or something I guess. Down to New Orleans and across to Florida taking 14 days more or less.

Sooo if anyone has a awesome forge they like show off or a club that might have something going on it that time let me know :-)

-

Awesome ! Now I want to see if I can use my dads lathe for a while.

-

Is true. Just thinking / hoping I could upgrade to a kidyon style in the future. When I have a compressors that could run one. So Trying to think outside the box a bit.

keep thinking I guess

-

Fe-wood:

Yep, noticed the rust in minutes between the vinegar and muriatic acid dips. I promptly sprayed them down after rinsing.

Rich:

Sometimes non-galvanized is difficult to source locally. I thought I would be better off using what I could get easily and stripping it. My knuckles are happily back to normal. I try to be safe, I have nitril gloves, just didn't put on a pair. I get complained at for making friends and family wear gloves, dust masks, ear plugs, etc., so I really should think more about it for myself. I thought the channel locks I used would have long enough handles, but the turbidity of the solution meant I could not see the edges to grab.

If there is a chemist here, let me know why the vinegar only dip set me coughing so badly. Obviously fumes were produced. Just post a nice (or not so nice) equation.

Someone should do a blueprint on chemical safety. I don't recall seeing one. If it exists, please point it out.

PhilI'm not a chemist but..

the reaction produces hydrogen, I imagine you reacted because as it fizzed small vinigar particles where carried with the hydrogen. Meaning you was breathing a vinigar vapour.

a chemist would tell you exactly but that's my theory.

andy

-

it's true you only asked one question. And you got an answer in the first reply, you also got a bit extra info for FREE

i don't know exactly your situation, but us young often guys think we can sidestep the learning process, but the reality is this was/is a trade. Trades today take 3-4 years to learn the basics. If these guys mention it its most probably true. Sure there are always other ways to do things too, so if it's not what your wanting to do right now at least be say thanks, and be great full for the advice they are only trying to help.

Andy

-

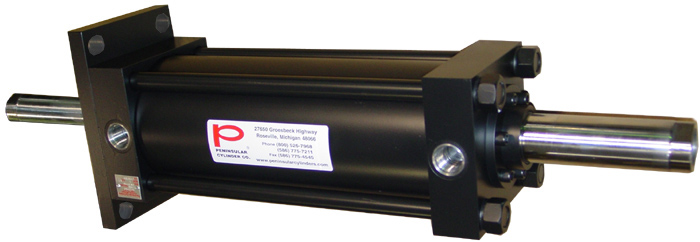

Cylinder shafting does not weld well as it is a high carbon very hardenable material. The rod bearings from cylinders are not designed for much side loading and will wear quickly. The piston seals will make much drag. If bound and determined to use something like this, look at Parker Hannifen brand "Jewel glands" these are a cartridge bearing used in hydraulic cylinders and are a kit you buy. Take the seal out of the bearings but use the rod scraper to keep the scale from eating the bronze bearing up. Us a long rod salvaged and use the threaded ends to attach to the ram and the spring.

Personally I have a spring hammer running with a tire clutch and a ram guide modeled off the Tire hammer. You only need to be able to weld plain steel, and be able to use a side grinder and a drill press. Thread a few holes.

you would need to machine the contact/slide faces of the hammer though wouldn't you??

-

Found one!

in Vises

Nice looks good

-

Looks great buddy!

Can't wait to make my first hammer

but gotta teach the wife to swing a sledge first.

-

Is the function of the spring primarily as a link and secondary as a spring ?

?? I hope so because that's what it does more efficiently.

thats why I raised the question does an air ram need a spring at all?

-

I have no idea what it's worth when l read this post then saw the second pic on the anvil I immediately said oh that's worth $100 (I'm thinking in Australian dollars) that don't mean it is worth that, or worth only that, it is just what came to mind.

but I actually was going to write just get her to price it. If you have not invested much in it but time and scrap steel, just say here it is what would you pay for it.

do that for the first 5 items you sell and you will have more idea what people will pay.

-

Can you copyright a style of forging?

( I'm genuinely interested)

-

Probably a little but with the ram at the front what percentage of the force is going into the link to the ram ? I don't know I'm guessing more than 50% plus the bolted on ram bracket is twisting in the other direction to wear the spring wants to flex. Meaning more force in efective in just that small part of the spring.

i guess a spring works by spreading the load over the whole thing. If you sit there and look at this set up, how much of the load is spread over the whole spring? Like draw it and estimate how much percentage of load each point on the spring has.

Seems to me it is focusing it to just 3" near the head.

Dont get me wrong this set up does work, and looks like the hammer does a awesome job. I just think if you look at the engineering of the spring who's job is to reduce the strain on the machine it can be better designed.

Still my favourite hammer though.

-

I aked the question to get you thinking about it. job done

Im guessing the spring is there to take the shock out?

this will be the style of hammer I build if I ever build one so the more discussion the better IMHO

fergy

ha ha see that's what I asked the question for in the first place, to encourage people to think about the set up as is at the moment. Every time I think about it I come up with that there is no where for the spring to spring to. Or that all the forces are working against each other. Meaning it (the spring) does basically nothing.

Was thinking someone might explain it. But I don't wana hijack the thread anymore then I have already. If I ever build one I might try open more conversation on the topic to see whe the collective minds come up with.

-

They do make double ended cylinders to "skip the middleman" of what it appears you are doing by welding cylinders end to end. They are not uncommon...just harder to find. I most commonly see them in lumber mills. Just last week I saw at least a dozen appropriate ones at the auction of a limber mill equipment supplier.

Would be far better than the hassles of welding....assuming I am understanding what you propose.

sorry bud I'm not so much thinking of an actual working ram just using the caps as a guide for either a new rod as yahoo mentioned or reusing one of the ones from th original Rams I cut up.

Hi Andys MQ,

Chrome shaft is very cheap in standard sizes, it should be possible to use the cylinder and caps from two rams and run a shaft through the middle and do away with the piston. there is only a seal and a rod wiper in the cap that the shaft exits from. the trick will be finding two cheap and crusty old bolt together rams to wreck.

Now we are on the same page, yes exactly. I was thinking about a 2" shaft diameter and just a standard ram cut and welded to each other and the frame rather than a bolt together.

however the bolt up idea might be even easyer. I was thinking of just using the shaft from one of the Rams I salvage. I was thinking the ideal ram would be 2-3"x 2'. Should get a good bit of stroke out of that. All depends on what can be found I guess.

-

I know this has basicly been thrashed to death. But I can't help but comment in a good debate like this.

But the reality is, everyone will think different about this question, it depends on the persons back ground. The way someone was brought up will determine how they feel.

someone from family in China ( or any other place in the business) , who's dad owned a company that made ripoff products and sold at a cheaper price will feel different to the guy who's dad made the original. Why? They have been taught different standards of what's acceptable. And have been affected differently by life.

So you can't actually conclude anything from this discussion as there are no written laws, only people's feelings. That in itself is interesting though, in Australia at least "art" cannot be patented. ?? You can decide if the has any bearing on the matter yourselves.

My take on the subject are as follows, if you feel bad for copying something ask the guys who made the original, or don't sell it. If you don't feel bad, like you have copied someone, you will sell it and never look back.

In reality here no one can own a bar twist, or some type of work. Even yellin gates besides stamping Samuel yellin on something you made( without owning or working for the owner of the name), copy what ever you like. No one has a patient ( as far as I know ) on the forging processes, or a style. I know this was not ment to be a discussion about legality but that's why we have laws, to tell what is ethically right and wrong. Any form of "ownership" someone could have is only because they do it better than anyone else. As I think was mentioned earlier.

If your the guy that's worried someone copied your stuff, get over it. We live in a world where even stuff that is illegal to copy is copied. The music industry for example, rip off are sold everywhere. If you are an artist of any description, just be the best. And be responsive to the market. If the other guy who copied you is under cutting you, your probably charging to much. Music artists now sell there stuff a lot cheaper to try get some sales. Is it right, not really, will you ever stop it, I doubt it.

Just go with it and make and market your stuff better then the other guy.

just to stir the pot a bit more ;-)

Andy

-

no it was just a thought I had the other day and thought I would throw it out there to see if anyone knew if the cylinders would withstand to strike rate.

Mum sure I can find a couple easy enough though.

-

there is always the other end of the spring in the equation to consider

if you mounted it that close to the other end would you consider it to do more?

yes it would do more. Im not sure how much more, but I believe you would get the most whip that way. But it would still be putting a lot of strain in one point of the spring,and I'm sure no one wants that much whip. Was just thinking if the ram was in the center it evens out the strain on the spring. And you control the whip by adding leaves ( is that even the right word) to the spring.

Dont get me wrong I love the hammer and it does work as is was just wondering if the spring is actually needed? Or if it can be used a little better? Or the engineering improved on? Can't hurt to talk about it at least. :-)

Either way looks like a sweet hammer rheis, can't wait to see it working.

-

Using the square section as the ram on your hammer do you need to machine the faces for the slide?

Zinc in a can?

in Zinc, galvanized, and coatings

Posted

It is not bad, it has a high percentage of zinc. Like 70% or something. You really need to give everything a good clean, at least a good wire brush.

If it is out in the weather I would try give it a coat of enemal or something over it to seal it, as it has a rather absorbent finish no doubt due to the high zinc content. In fact I think all, if not, most zinc paints are designed as a undercoat and if used like that they are great.