-

Posts

53 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by S.Hollowood

-

Forging hooks with tongs

S.Hollowood replied to Joel OF's topic in Blacksmithing, General Discussion

I was taught to not use tongs to create curls at all. I draw out the curl area square, break the corners, and then round it off. Then i place just the tip of the piece off the far edge of the anvil, using an angled hammer strike i being the curl, turn the piece over using more angled and drawing hammer strikes i finish the curl. -

Just want to share the news and my excitement. I just got the last of money i needed to order my belt grinder. Email sent out, now i can't wait. I decided upon the Coote with a 10" wheel, and a glass platten. Found out one of my friends has the machine and can't be happier with it, even after using promachines at a local hammer in. I have used it before, and liked it, after researching for the past year or so, and doing all of the work with a cheap 4" by 36" belt sander, i figured it was time. Thanks for all the help you guys, and this forum have given me!

-

I am in the U.S. on the East Coast. Thanks for the advice Rich! I have some 1" 1/4" mild stock that i have laying around from a candle holder scroll project that i might use. I have used the 2 x 48 belt sander at the local guild, but i am moving onto a coote 2 x 72 with the 10/8" wheel and glass platen. I haven't used something that big before, I have a 4" x 36" belt sander that has served faithfully as i got started, but it is time to move onto decent entry level machine.

-

I am going to be purchasing my first belt grinder in a little while (next month or 2). I was hoping that some of you on the forum could share some of your techniques, or possibly point me in the direction of a knife/sword maker in my area who might be willing to help me. In exchange get an assistant for any project they might be undertaking.

-

Watching the episode right now, the series follows Todd Kaine as he moves forward into production and custom knife making with his brothers. I didn't even know this show was being made! Good thing more exposure, bad thing more exposure....

-

First off these are absolutely beautiful, i have always loved clean beautiful lines like those present in these. The bog oak is beautiful too, mind telling me the thickness, and width of the larger of the 2 blades?

-

This is a little off topic, or maybe it isn't, anyways i have been making knives and other sharp tools for a while now. I have begun to invest in better and larger tools, moving away from a cheap 4"x36" grinder into something a little more dedicated and precise. I have been looking around on craigslist for a while and came across an old belsaw 1" belt sander, and am considering getting it. My question is what does the forum think of these machines? Do they operate at a high enough speed to be efficient for grinding bevels and such? Can they handle hollow grinding on the contact wheels? Are they worth the investment?

-

Beginning to go nuts, the steel is paid for, now i am just waiting for it to ship.

-

Thanks for the clarification.I will definitely consider copper for a spacer as well make sense in my head now that i think of it.

-

Good to know about the wrought iron, i only worked it for a few minutes the other day; i was pretty tired from some knives the other day. It doesn't work so well at a lower cherry temp and did flake out a little bit. Thanks for the information. I am planning on turning the 2 wood pieces on my lathe, possibly turning the spacer in the middle all in one piece. I haven't decided yet. I was thinking something slightly more exotic for a spacer, something to highlight the wrought and darkness of the steel. Ideas?

-

-

Actually i mean real wrought iron complete with slag and silica. I am part of a local guild which fortunately has a pretty large selection of wrought iron. Story goes the wrought was pulled from a dock out in the Harpers Ferry area supposedly put up for the Civil war. Truth and completeness of this story......well who knows. I plan on etching the wrought once everything is mocked together and fits. I don't plan on leaving hammer marks in the steel, but i do intend on leaving the pitting and discoloration on the steel from the scale and forge work if it turns out decently.

-

If only i were in Europe, i imagine a search of arms and an armor within museums turns up quite different results than it does here on the east coast. Most of my local museums including the wonderful Smithsonians are very limited in arms, especially edged arms. What there is present is typically Naval edged weaponry,as well as bayonets, and fighting knives. Indigenous weaponry does appear, both for Native Americans, and from other races whom we have quarreled with which while interesting isn't quite the same as Arming swords, dussacks, and other such classic European weaponry. Guess a trip abroad is in order, maybe in a few years where i can be far more help in a blacksmith shop i will have to do a tour of blacksmiths and bladesmiths trading work for experience.

-

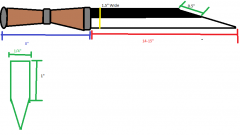

I'd love any constructive criticism on this design i have created for my first larger project. I have done a lot of knives from the 3-7" range in blade length and i wanted to move up to something slightly larger. So i started doing research on different blades and i have a few in mind for the future if i can pull off something in the medium range perfectly. I chose the given dimension and materials as i have the materials all in hand. All of the metal fittings will be made from wrought iron, which i have not worked before, but i do have some class time, and a teacher i can refer to. Although information and helpful tips are welcome. The handle material will be made from walnut as i have plenty of that laying about and it should fit the rough forge look perfectly. http://www.iforgeiron.com/gallery/image/36912-seax-design/

-

*scampers off to the interwebs to find an arms museum locally* *hope in his eyes* I am headed to the guild meeting tonight, and i know there is at least one bladesmith among them who has done larger pieces, hopefully he will have time to talk with me. I wish i could find someone in the area willing to have an apprentice or at the very least a shadow for a day or 2.

-

Both wonderful pieces of advice Thank you. I guess that is why my conception is so skewed, having seen almost nothing but reproductions my mental image would be way to thick and heavy. I guess i need to find some real examples of historical blades, Can any one recommend a decent title that would be helpful to a bladesmtih in that it list pertinent specifications?

-

So i have been making knives for a couple of months now, and have made various designs from Kerambits, bowies, sheepsfoots, and all sorts of different things. I have mostly been working in the 1/8" x 1" as well as 3/16" x 1.5, and the occasional 1/4" piece. I am planning on starting a dagger soon, My basic concept for the dagger is based on the classic arming sword design. With a few design changes, with a maximum length of around 14" , a blade at the hilt slightly wider than an inch or so, in between 1.25" and 1.5" With either a very slight taper to the tip, or none until about an 1" from the tip. For the cross section i would like flat grind on both sides and a central spine on each side of the blade or in other words <> . Now my question for you guys is this, i am completely unsure of what thickness to start with to reach that profile. I feel like 3/16 and 1/4 or to thin, how ever i don't have a big background in blades, much less historical blades. So my question is this what is your recommended thickness to start with?

-

Metal work projects of a different kind

S.Hollowood replied to newbieforge's topic in Blacksmithing, General Discussion

They are fighting against the Syrian Regime, those photos are amazing though.- 10 replies

-

- metal work

- lathe

-

(and 2 more)

Tagged with:

-

So i did a lighting gig in D.C. the other day, up off of Wacomb to be specific. Anyways at the end of the gig as we were loading the truck i noticed a rail road spike lying in the grass. So i grabbed it being the blacksmith opportunist that i am, didn't really pay attention to it until i got home. Which is about the time i noticed its only about 4.5"s long, coated in some sort of anti corrosion coating, and has a k emboosed on the top. What i want to know is what in the world would a mini spike be doing in D.C. does anyone know?

-

Why use files for knife blades? What is a dull file for a wood worker, or other softer material is often perfect for hot files in the shop.

-

Thank you!

-

I guess i should have clarified, by eye punch i mean a punch used to create eyes on dragons and such. Not a punch designed for the eye/socket of a hammer. The larger stuff i can deal with, it's the small finicky shapes that i trouble with. Though thanks for the video!

-

So quick question, i have taken a basic blacksmithing class and made a few tools here and there. Being short on funds i have begun making what i need where and when i need it. (or what the rest of the world would call "normal practice") Anyways i can't find much information on the more single purpose punches, like info on making eye punches, ball punches, and those sorts of things. Any links or info the site can provide would be wonderful.

-

101 Metal Projects for the Novice Blacksmith

S.Hollowood replied to svincent's topic in Blacksmithing, General Discussion

I was not aware of this book, and being a novice blacksmith myself, i shall now endeavor to find a copy. I will let you know if i come across a site.