-

Posts

276 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by David Kailey

-

-

Muriatic acid works good to remove rust, I use it a lot. for a coating I would have it powder coated clear.

-

2 hours ago, olfart said:

That's some beautiful work, but it raises the age-old question; "If it's an occasional table, what is it the rest of the time?"

Storage Table.......Cause if its anything like mine it ends up being the collect all.......mail, keys, books, school bags, glasses......ect

-

19 minutes ago, Jackdawg said:

Very nice, what is your technique for the texture on the flat steel?

A 5" wide cross peen die in my Big Blu power hammer.....lol.

-

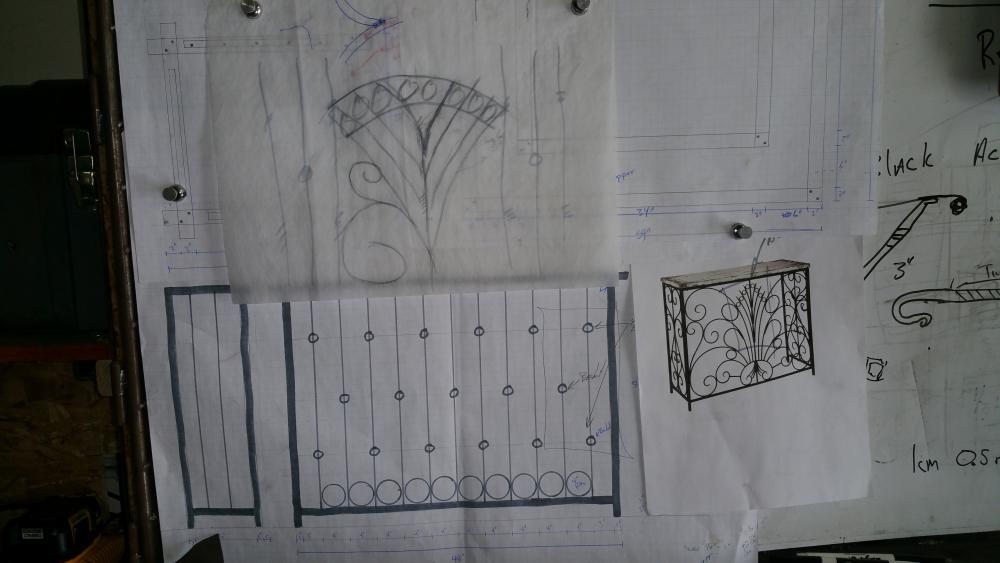

So I sat down with a customer and we finalized the design. Even laying out the bar stock and looking at textured samples. All was approved, but when i was finished she said, she didn't like it because it looked to "heavy" lol........deposit forfeited.

But I made a few modifications and was able to sell it with a glass top for a couple hundred more then I was commissioned to build it for. Many off you may not agree with what I did next but I returned the customer's deposit.... she was very happy and she said she wanted to get another piece made so I gave her a number to a designer I like and said she could help her figure out exactly what she wants....... That way I will get a set of plans and so long as its built to spec. I will get paid and the designer will have to fight it out with the customer. lol

-

-

Well,

This project was for 44ft of branch railing. I got about half way done when the trailer I had the stuff stored in got stolen.....so i had to start all over.....

But, it had to be done so, done it got.

The section had to fit into an existing railing. It took 6-8 hrs per foot to produce a finished railing and install it.

But it was a good summer job and my daughter worked in the smithy 4 days a week helping and that was fantastic time to spend with her. 13 years old and is efficient using all the equipment in the smithy.

So....... all total 1500 ft of bar stock, hours of texturing, fitting, welding, grinding......lol life of a metal worker.

-

On Sunday, May 22, 2011 at 8:08 AM, Steve Sells said:

The future for the south is hiring out work to legals, undercutting our ability to work and support our families? wonderful.

I enjoyed it when everyone was coming down on the fruit growers in California for hiring "illegal immigrants" how it was taking jobs..... bla bla bla. So a very large grower guaranteed everyone who wanted a job....a job. 93 non ethnic/ illegal immigrants showed up for their new job. Before lunch of day one 28 quit, at the end of the day another 9 walked off the job. Morning of day two only 13 showed back up and only 6 lasted the day. The reason people don't have a job is because they don't want one. People arn't willing to "lower themselves" by taking a lob they feel is beneath them or work a job because it's "to hard." I have owned 3 companies over 25 years I start guys out at $15 an hour min here is $9.80 and it's the same crap........they can't hardly make it past the 2 week training and they always ask.........when's payday, show up late, have to be told what to do.....I will go thru 9 before I find one who is not great but acceptable. I worked in a field that has codes to protect from fire and if they were ever enforced by the authority having jurisdiction they I'd have more work then I could ever handle. Every year people die and 4500 buildings are lost because these codes are not enforced....so for me illegal immigrants arn't steeling my jobs....... city managers, fire departments, and lazy food inspectors are. But I don't cry about it. I get up, I go to work and I fight for the work I get. I bid against companies who dont pay taxes, workers comp, insurance, license or several other required costs, and i still make a living and I still aupport my faimly. So I say get ofg your butt and do what you have to if you wanna support your family, hustle, hustle, hustle. .....the world don't owe you anything.

-

10 hours ago, Yuppiejr said:

If a blacksmith does a demo that is mostly entertaining and a little bit informative to grade school children (hello 90 second attention span) being "undignified," or are they playing to an audience in order to promote the craft long term?

The shows aren't written and produced to be documentaries for blacksmiths like the stuff on PBS (which also have a vastly smaller audience), they are written to entertain following a fairly specific formula that appeals to the largest possible audience... but still gives a taste of blade-blacksmithing and fabrication techniques to an audience that knows nothing about the craft. If someone wants a specific in-depth overview of forge welding Damascus steel billets I'm going to go out on a limb and assume that most experienced blacksmiths are not using Forged in Fire as their primary "how-to" source for information vs. the advice of a more experienced smith, Youtube or a specialized forum like this...

I give credit to anyone who gets in the arena and puts their reputation out there on a show like this, a LOT of trust has to be put in the producers / editors of these shows who could make or break their reputation and business long term. To 'purists' it may seem silly or undignified, but at the end of the day there are probably very few smart business-people who would not jump at an opportunity like this for both the direct paycheck and the huge promotional opportunity the show affords them.

I happen to personally know 3 blacksmith's that were interviewed by THC for a new show..........they all said the same thing as did Rory May. It didn't take long for them to figure out they wanted a smithy with drama and that it was not about blacksmithing so much as drama seasoned with blacksmithing. Honestly what you said is the problem with the world......everyone is willing to sell out and everyone is willing to watch crap cause its the in thing. Why are we so willing to sacrifice things of high value just for money..........morals, dignity, self-respect, it's easy to sell out. I respect the people who did not. Those who stood tall for their beliefs, dignity, craft...ect. Shows like this provide a false representation of what these trades are about and those who have spent lifetimes trying to preserve and share what they have learned. I respect what they do and have accomplished but why, why, why say and do things that are a complete lie.........tongs have a right and left side? I hand cut these Indian Motorcycle logos, got to forge weld at 3000 degrees, I can't find a new part in one of the biggest cities in the US ie industrial capital.........just let the work speak......it's good enough........

-

I alway appreciate skilled tradesmen. Milwaukee blacksmith aired a show this week were the crew built a steel bar for a man who loves Indian Motorcycles. This episode claims that Miles "hand cut" the 6 Indian logo plates with a plasma cutter, and how Miles has become unbelievably skilled hand cutting with a plasma torch ................ well they are right I dont belive it. There is no way in the world they were "hand cut." What's stupid is why make that claim? Anyone who works with metal fabrication can tell they were cut by a computerized cutter. It the logical thing to do, because of the lettering and detail in the logo. So anyone in the trade would cut them using a automated cutter........I don't understand why producers need to sensationalize stuff with lies. I dont under stand why Kent the father would read that false commentary and let it be aired. When a show starts saying stupid stuff like this it makes me want to stop watching. The guy on Iron & Fire claimed, you have to make a right and left handed side to make a set of tongs???????!!!!! REALLY!!!!!. Go ahead try that let me know how that works out for yah. Forged in fire claimed you have to forge weld at over 3000 degrees!!!!! Huh.....considering steel melts around 2800 Fahrenheit???? Maybe thwy were talking aboit "casting a blade. Lol. These crafts are appealing enought all on their own! Stop making untrue claims, it doesn't draw people to the show but actually drives people away. I have stopped watching several of these trade related reality shows because of the stupid drama from the cast and the lame claims made by the cast and producers. You have to be honest about the work and you have to find the balance and I think it should be 80% about the trade/craft and 20% about the cast. Either that or rename these shows Days of our lives-blacksmith edition, The young and the Restless forge knives.......ect if I want stupid drama I'll stay home and watch soaps.

-

I had some left over 1/4" steel ao I cut out a square and dropped it down about 2". Added a tweener I bought from an old smith in Simms Montana-he got it from his great grandfather who brought it up in the 1880's from down south some where. I salvaged the legs from a Davis & Wells table saw I found at the scrap yard.

-

I own a 110. I have used it for days texturing 4" x 1/4" flat bar (800 ft of it) and have over 1200 hrs of use on it. I recommend the 110 because it will do 90% of the work you'll need. I found the 65 to be a little light. You absolutely need to torque wrench your dies in place. I oil my guides everyday and grease the gap in the lower die (prevents scale from jamming it up. I have a 7.5hp 80 gallon compressor and it seems to keep up just fine. Josh at big blu is tops!!!! I am actually looking for a 155 so yah I would recommend big blu.

On Wednesday, May 04, 2016 at 6:37 PM, marcusb said:I ran the guts out of one making pattern welded steel for one week at a class. In the week I ran it the signal switch failed, the valve for the treadle locked up and some bolts fell out but I cant remember were, it was 2 years back. Also the dies would not stay tight and kept walking out. I was interested in them myself until I got to see and use one, after that I was not impressed.

I feel this is a pretty unfair assessment of big blu. There are only a dozen bolts on the entire hammer. If you don't torque the dies in place they will come lose. I have a lot of long hard hours on my 110 and have never had any issues. Sounds to me like you used a hammer that had no maintenance being done and was owned buy and idiot who just refused to follow the little bit of recommended maintenance there is...........IE.....check the guides weekly, oil them daily, torque the set screwd on the die holders........... I am sorry you used a hammer in poor condition. I torque my dies rune a few minutes and check the again, never had the dies come lose. I can't imagine the irritation you must have experienced but it was not the hammers fault, it was the owners fault."if your not there for your tools, your tools won't be there for you!"

-

-

Its a commission. I rolled the dice in February, rented a 900sf shop here in Spokane, Wa and started to pursue work. So far so good I have had good work for 2 months now and just landed a 44 ft railing job that will take 6-8 weeks. That will put me in the black for the year and pay the rent thru november. so I guess it could be said I am living the dream. lol

All be it this commission id for my father inlaw so I am just getting paid my cost. But with out him I would never have my wife so I think I am way ahead!!! 20 years this August!

5 hours ago, Frosty said:Very nice Dave, I like it. Is it a commission or did you make it for yourself?

Frosty The Lucky.

-

-

I just finished and installed this railing its 14 ft long in 3 sections took me 100 hours from start to install. The customer wanted a thicket of branches that looked real and had no 4" holes so the railing would meet code. It was hand sanded and waxed. I had to weld and grind over 150 "nublets" (cut off branches) the railing took 400 feet of round rod ranging from 1 1/4" down to 3/8"

I was very happy to finish the railing and move on to some thing else but I got a call the day before install and another customer saw my web site and ordered 43' of this railing. I changed the design a bit but it will take about 300 hours for the next job............ not the most technical work but it is an art form and it takes time to put it all together fitting each branch properly.

-

-

i don't really care. but I hope my family and friends are not like those of the bad American Idol singers who think their great but really stink because their family never told them the truth or apparently live in a different world then the rest of us. I learn everyday, i get better everyday. i never look at my old work and think, "boy thats bad" cause in the moment i made that piece I did the best I could. So as I said I don't care what I am 1-10 I just care that I preform at a 10 with the skills I have at that time.

-

god keep blacksmiths around so welders, machinist, superman, and Chuck Norris could have hero's to

-

On 3/8/2016 at 6:34 AM, Charles R. Stevens said:

I don't believe any one mentioned a striker, a 6 or 8 pound sledge and some one who can wield it will help. It's best to use top tools for this as it saves the edges of your anvil from missed blows. If your helper understands what's going on, either of you can be the hammer man.

I totally agree. I would strike "deals" to use my buddies as strikers. its pretty amazing how much striking a guy will do for a 6pack. lol

-

ahhhh. There are no muscles in your hands. there are in your forearm. So??????????? my hands have swelled up from hours of heavy forge work but never stayed that way. But you may want to look into that medically.

-

On 2/5/2016 at 9:28 PM, Daswulf said:

Beautiful piece. wait, where is the light, am i missing something or Daft as usual.?

Frosty thanks. I'll keep the tidbits in mind. I too need the lessons.

the light is hidden away between the 1.5" texture flat bar along the bottom of the piece. I used LED strip lights that just glue on and ran the wires thru the tube frame.

-

9 minutes ago, Frosty said:

I like the big blows too, they really make the steel's plastic nature stand out a person can the see it's transformation without the specialized experience of being a blacksmith.

Nice, how do they sell?

Frosty The Lucky.

They sell pretty well once i figured out the right textured to make them appealing to the eye. You can tell the two hooks toward the horn of my anvil are just to busy, they don't look right. over and over people would pick those two up and put them down and grab a different hook to buy even if the shape was the same. I am glad i picked up on it cause making that discovery made a difference. the only reason they were different was because I was figuring out the best way to produce them quickly and over that process the look of them changed. I actually liked the ones made later better also. I just didn't know why until later.

-

I added a few more pics. I was just tough to get a good picture because of the lighting and the fact that i don't have a clean white 15 foot wall in my shop. lol

I would go take better ones with the right light but its a 70 mile drive.

-

These are hook I just came up with farting around during a 10 demo at the state fair in Spokane, wa

Call them Steam Buff Hooks cause that is the organization that has me out to do the demo.

Figured out the fewer bigger odd hammer blows creates the right visual effect of "facets" on the hook. If you get to many it looks mauled up, and unshapely. Less is more. I like em they are fun to do.

![20160430_130410[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c53e93121_20160430_1304101.thumb.jpg.db29a7502970b7d7c08613796db36792.jpg)

![20160430_130428[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c54a51c38_20160430_1304281.thumb.jpg.c343da0acf33c39de20736b8426cc9ff.jpg)

![20160506_120010[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c554e0965_20160506_1200101.thumb.jpg.fb9ed6798ec7d6e1d53c97535044dd7b.jpg)

![20160510_163329[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c55e09811_20160510_1633291.thumb.jpg.bc8b36c0536493683e2a0cbfa1b67a03.jpg)

![20160510_170659[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c574dc096_20160510_1706591.thumb.jpg.4705e1b0ad0000eebc3a2464c54cba50.jpg)

![20160510_171556[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c6398b0af_20160510_1715561.thumb.jpg.c5a0813bae38fd8b384d663e0cd34785.jpg)

![20160406_114248[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c25731e54_20160406_1142481.thumb.jpg.763a5349014325aa5e7a555036da77aa.jpg)

![20160414_163616[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c2855582d_20160414_1636161.thumb.jpg.0482bf609d2f05a10b8f66a503787587.jpg)

![20160425_163221[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c2a9c439b_20160425_1632211.thumb.jpg.7af831027597234b873b08114099a5d8.jpg)

![20160505_152640[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c2d957e12_20160505_1526401.thumb.jpg.a09c20a28d293c91d2f0b4f1ad418bdb.jpg)

![20160502_172511[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c2f23ca9e_20160502_1725111.thumb.jpg.ac3b795c06a0d9716941305080c2d076.jpg)

![20160502_172531[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c302c2d33_20160502_1725311.thumb.jpg.ab13ebfb9091e4f3f0795f493541eb54.jpg)

![20160505_152649[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c30faa3b0_20160505_1526491.thumb.jpg.cccde373b696628d04bef3dd60938310.jpg)

![20160505_152831[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c328ec41f_20160505_1528311.thumb.jpg.b8e37ef8a303fb98e96229a1291cd33f.jpg)

![20160505_152725[1].jpg](https://www.iforgeiron.com/uploads/monthly_2016_05/5732c34ddc842_20160505_1527251.thumb.jpg.c5ddae2153ff4708885af7476260c89d.jpg)

.thumb.jpg.dda90701637c4170248b50c5f9090213.jpg)

hooks using a penny ends, and Fullered RR spikes.

in Member Projects

Posted

These are just a bunch of hooks, from scraps, and repurposed steel......ect.

Usually I come up with these projects while I am demoing, at fairs, event, and the such.

I did like the reversed Penny end..... i think its a nice way to finish off a hook.....the shepherds hook has been pretty played out i think.