-

Posts

103 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by gator13

-

-

Sweeeeet

-

удивительный hope i got that right

-

grandpa seems to be a good teacher.. WAY TO GO LITTLE DUDE

-

gentlemen i appreciate the input.. i was trying to go with a design that i thought was simple.. CH your hammer design looks and works great it just seems like too much linkage for me... i just came across the clay spencer inline and i may just have to build one of those thanks again fellas

-

reading some of the trouble some have with a normal treadle (hammer and anvil not lining up with dies and tooling)..

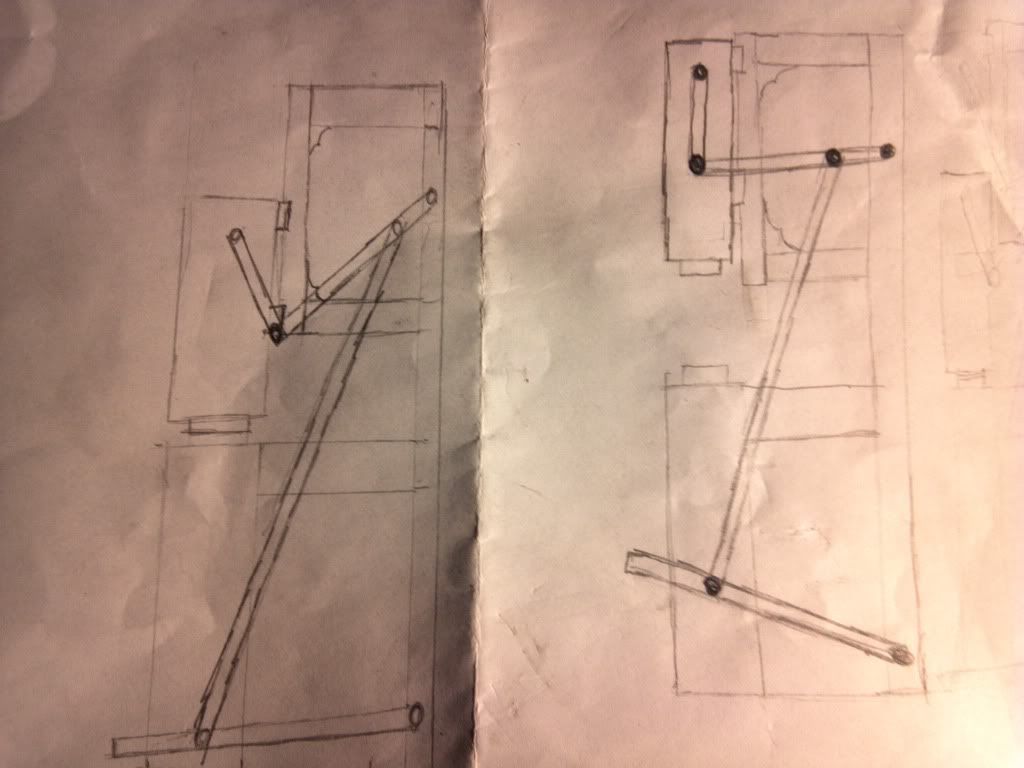

i wanted to come up with an inline that was simple and easy to build. sooooo this is what ive come up with.. planned on using something similiar to thompson rails/ linear rails for the hammer to slide on .. and something similar to a clevis for hingepoints between link bars.. im sure you can pretty much tell whats going on in the pic ( i hope :unsure: ).. the plan is to make the longer link bar adjustable on both ends.. and obviously i havent come up with a plan for the spring.. other than my obvious lack of artistic skill what do you fellas think?

-

Today is international blacksmiths day. Why is there not a huge party going on here?

-

i hope you can get em both fully operational... any pics of the one thats painted?

-

not really sure if it makes much of a difference but if you look at the hole for the screw assy. you can see that it has been forge welded.. also down lower on the legs theres some evidence of it.. which i dont think is visible through the pics

-

alrighty fellas i got er all cleaned up and greased. got a small coil spring from an old bicycle with a springer front end pushing out down near the pivot point (temporary) til i can get a leaf put in it... i found some letters.. not completely legible, but i did get something.. just lookin it over after i got it put back together i noticed a 5 just to the left of it was NO as in the first pic.. but the part i cant seem to figure out is the smaller letters which is slightly under and also to the right of the messed up looking H near the top of the pic... (the H isnt part of the lettering) from what i could see, there were a illegible letters then W (space) couple more illegible letters NDO and possibly another N

-

the bracket is remade.. just looking at it i dont think the spring belongs to it.. its about 4 - 4 1/2in. wide.. im going to tear it down and get it cleaned up sometime this week and see if i can find anything stamped on it...

-

picked this up for pretty cheap screw looks great just needs a spring .. no markings or stamps anywhere on it that ive seen

-

yaaaaa id say that table is too big.. ill take it for ya.. btw how thick is that steel?

-

ugh i hate neighbors

-

Can't argue with that. Been telling myself for a few years that I wanna grow my own. Just seems that it would take up too much time.

-

Thank you sir. Will do

-

I finally got the blower hooked up. To maintain heat 1crank over about 4seconds is all it takes a little faster to warm it up a bit. That thing is awesome

-

Gerald having that story makes owning it a million times better. Wish I Coulda got the anvil too just to be able to keep em together but she said I already had one. I really appreciate you working with us on that too. I have a friend that is looking for a blower. And I haven't had a chance to ask any of the saltfork guys yet. So if you might know where anymore are holler at me

-

Nice anvil. Love that stand too. My stand is 9 4x4s standing up and there not all cut straight so its got a little wobble. I may have to rebuild my stand. Good work

-

Edited: looked at the post again. And found out I dont know how to read "COLUMBIAN"

-

My opinion ... you better go get that before someone else does

-

Darn good looking blower. Hard work pays off.

-

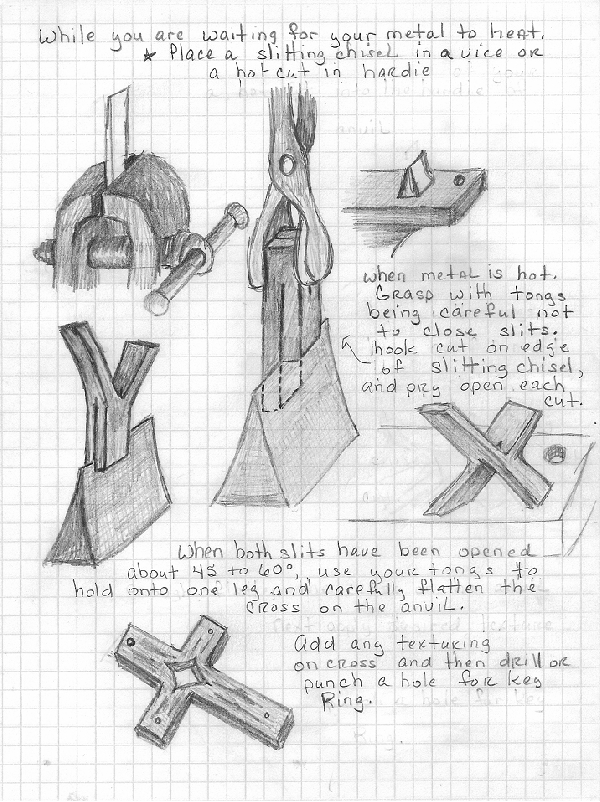

Picture 1

Picture 2

Here ya go bud. Welcome to the site.

Not too sure on different sizes but I hope that'll get you started -

Happy Jedi day

May the fourth be with you -

Clean it out, stuff a light bulb in the upper canister, and put it out by the road with your house number on it.

Give it a couple years and some crazy blacksmith will try to buy it and complain on the internet about your lack of respect for old equipment.

Lewis

not a bad idea

i love all you other guys.. youre awesome

Show me your Forge

in Solid Fuel Forges

Posted

jesse has a very unique way of showing off his toys that car is just a bad XXXXX as the " LAZER BEAM " behind it .... PEW PEW PEW LAYZUUURZz