-

Posts

61 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Tagg

-

-

See, I've heard of them before, but I never knew what it was really. I've put plenty of books on hold, but never knew that you could request a book not in the catalog and have it transported to your library. Thanks for telling me about this! I just did 2 ILLs for the $50 knife shop and the complete bladesmith.

Zachary -

So theoretically, I could change differently cut MIG tips to change my forge atmosphere? Or would it just be easier putting duct tape on the air intake.

-

That makes a lot more sense. Thanks Matt

That's a good idea. They actually don't have that book in any library near here, so I might order it soon. We'll see. I just got a few books from the library on blacksmithing techniques yesterday.

Zachary -

Lean produces more scale?? Huh. I thought scale was oxidation, so a more lean environment would have less oxygen. Is this not the case?

By the way, blades would be the majority of work that I would be doing.

Zachary -

I'm curious, because, the way I see it, there is no advantage to running your gas forge with a "rich" environment. This is because scale does not form as much when the forge is lean and there is less production of CO. Are there any reasons why it would be better to run your forge rich then? I'm stumped.

Thanks,

Zachary -

That's amazing Timothy. In the summer too right? Wow...

Zachary -

Yep, you got the wrong part. It's not a coupler you're supposed to get. I'm really new to brass fittings and terms, so I assembled my list together and just asked one of the guys where the things were. As Phil said, it's a 1/8" MPT on one end and on the other it's a 1/4" compression. Tapping is really new to me also. I tapped my compression fitting for the mig tip crooked, so I bought another and am going to use the drill press to keep it straight while I manually turn the bit.

Here's what I got:

Here I already drilled the hole at the top of the "T". I also attached a brass piece that I had in a box of fittings. I'm not sure what it is, exactly, but I kind of acts like a flare and enables me to attach the burner to the hole in the firebrick.

These are two different compression fittings. The top one is 1/4" MPT x 1/4" compression. The bottom one is 1/8" MPT x 1/4" compression. Why? Scroll down.

Here's the setup. From right to left:

Gas comes in through a 1/4" hose into the the 1/4" x 1/4" Ball Shut-off Valve

On the other side of the valve, there is the 1/4" MPT x 1/4" compression fitting

This attaches to the 1/4" copper pipe (Not shown--I don't have it yet)

The other end of the copper pipe attaches to the other 1/8" MPT x 1/4" compression fitting

The 0.035 MIG tipscrews into the tapped 1/8" MPT side of the 1/8" MPT x 1/4" compression fitting (Use 1/4-28 tap with a #3 drill bit)

The 1/8" MPT x 1/4" compression fitting then screws into the tapped "T" (Use 1/8-27 Tapered Tap)

For more information and if you need to ask any questions, go here: http://www.iforgeiro...-and-made-this/

Zachary -

Yeah it can be hard to find all the parts that you need. I just stopped in to our local hardware store today and picked up most of the stuff that I needed. Only thing is, they didn't have a 1/8-27 Tapered tap. Kind of disappointing, since it looked like they just ran out and they wouldn't be restocking in a long time. I'll have to go to Lowes soon and pick up some copper pipe and see if I can't find that tap. After that, I just need the firebrick, regulator, and hose, and I should be set.

Kudos,

Zachary -

That's where I was going to get the plistix from. $3.00 per fire brick seems very good. You've got me thinking now. Thank you for your advice!

Zachary -

My popcorn tin is 9" diameter x 9" long. With 2 layers of 1 inch ceramic wool it would give me a working space of about 5" diameter.

-

Would it be a good idea to use the limited Kaowool to make a well insulated coffee-can or popcorn tin forge until I can afford to acquire the amount of insulation (Firebrick or kaowool) for a bigger forge? I'm starting to think this would be the ideal thing to start with.

-

Kraythe, I do not know what kind of bricks the person I know may have, but I will see. Do you realize I will have a 1 inch layer of Kaowool lining the inside of the bucket along with the firebrick? Would that still make the bucket a glowing object?

Zachary -

My shop used to look like a tornado went through... even after I had done a 4 hour clean-up several times. So a few weeks ago I decided to do a thorough cleaning (I mean REALLY thorough cleaning) and put a big bold sign up in the shop. It's been about a month and so far so good. Here's the rules I've put up on the wall...

BEFORE YOU BEGIN...

Start with a plan. What do you wish to accomplish today?

Remember to wear eye-protection, lung-protection, and/or gloves when necessary.

BEFORE YOU LEAVE...

Put everything back where you found it.

The workbench should be clear of all tools, current projects, wood, wood chips, sawdust, and metal filings. Keeping the workbench clean keeps it safer and more enjoyable to come back to next time.

If you are frustrated, STOP. Go inside, think about the problem, and then come back to the project. Keep the shop an enjoyable place to work.

~~~~

Feel free to edit, modify, and give suggestions.

Zachary -

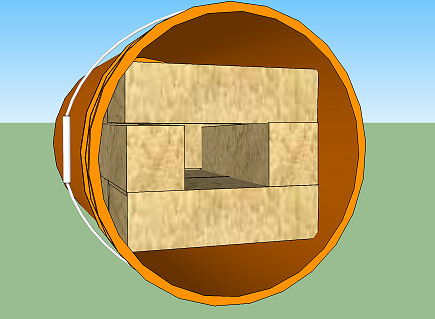

Those are some good points. I'm not sure the dimensions of the firebricks because I'm going to ask someone I know if he has any extras, but I did a google sketch-up of 2.5"x4.5"x9" firebrick and here's what I came up with. The 2 side bricks are cut to probably about 3" high.

I was thinking I could cut a hole in the top or the side and put some extra kaowool insulation where the burner hole is to make a small tunnel leading to a hole in the firebrick so the flame can go through. The kaowool would be lining the inside of the bucket. I have the lid for the bucket, so I would then put the lid on and cut a square hole leading to the firebrick compartment.

How insulated and efficient would this design be?

Zachary -

Hello everyone! This is the first topic I have posted on IFI, so I should probably introduce myself...

I'm Zachary Bruno, 16, and I love the creativity in knifemaking. I have made a couple knives so far (One stock removal, one forged). I'm relatively new to the knifemaking world and a kind knifemaker in our area recently gave me a RR track anvil, a few pieces of HC steel to work with, and some Kaowool. I had been forging with a homemade charcoal forge and a hairdyer, but that was getting way too expensive way too quickly.

So, I changed my perspective and decided--after some advice from other experience members on another forum (Paleoplanet)--to go ahead and build a gas forge. I want to build something that will be durable, last me a long time, and be able to accommodate my increasing skill in knifemaking.

I decided the T-burner (Phil's tutorial and Frosty's concept) would be a great option.

So far I have a 5-gallon metal paint bucket for the body of the forge, enough Kaowool for one layer of the forge, and the burner parts and taps. (I'm planning on using firebrick for the interior)

What's left?

Regulator and Hose (http://www.amazon.com/gp/product/B000VXEW4G/ and http://www.amazon.co...uct/B002LH46IC/ <-- Is this hose OK?)

Plistix

Zoeller flare

A piece of pipe and washer rings for the burner holder assembly

1/4" ball shut-off valve

So my main question right now (And feel free to give me other advice) is... could I use a 1/2" shut off valve--which I already have--and bring it back down to 1/4" on either side or do I have to go buy a 1/4" shut off valve?

A reference: http://zoellerforge....legasforge.html

Thanks guys!

Zachary -

That helps, thanks!

Are you using refrigeration copper tubing or just copper tubing? If you are using refrigeration copper tubing, then what size are you using? I think it measures differently.

How tight does the compression fit between the copper and the compression fitting be?

Zachary -

The blade shape and the handle shape fit together nicely. My favorite part of this design is that the handle starts before the tang straightens out at the bottom side of the knife.

Zachary -

That's quite nice. I agree. Adding some type of string wrapping to a part of the handle (Like right where the bamboo ends and the blade tang sticks out) would look really nice.

Zachary -

I you made the handle material longer, you could end it squarely right before the blade starts. That would look more finished.

Zachary -

Ok, now there is one more thing added to the "I'd like to make" list. Awesome.

Same. This is awesome!

Zachary -

How many PSI does this burner run on? Would it be okay to get a 10PSI regulator and hose or a 30PSI?

Thanks,

Zachary -

He made a good point about wanting his apprentice to "surpass him" in the skill. Makes sense, but I don't hear that too often.

Zachary -

Great. That's what I wanted to know.

Thanks!

Zachary -

Anvil bounce is when the anvil bounces or when the hammer bounces on the anvil? The stand, nor the anvil bounce, but the hammer does bounce on the anvil.

side or top burner?

in Gas Forges

Posted

I was wondering this too. I've pretty much decided on putting the burner on the top. Safety, easier to store, easier to hold in place (IMHO).

Zachary