-

Posts

110 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by hiltsbilt

-

-

congrats on the first fire!!! Its great fun and addicting, cant go wrong playing with fire hehe

-

here is my new one sitting on a temp cinder block stand ill make something more stable latter. its 450# German with no markings and I got it for just a hair over $2 a pound :)

here it is with my 90# on top :)

-

well got her cleaned up put a little paint on her then proceeded to scratch sed paint moving her into the shop lol no biggy but she is there :) happy day

got my 90# on top lol looks so small now

-

i let her go shopping:) lol

-

update, got her out of my car and in the garage and on the floor. im planing on using some cinder blocks for a temporary stand then ill make a better one:)

:)~

-

thank you guys.. I will post some pics in its new home probably in a couple days or so. DC, It was in Rice lake WI at a farm. ya black frog thats him :) I loved seeing all those anvils, I didnt even get pics of them all just a few of them, are you buying an anvil BF or just visiting?

-

So I found a an add on craigslist for a 450# German anvil for $975. so I look at my wife and she said go for it :) YEE HAA.. only downside is its 280 miles away. but I drove it anyway. here is some pics of what i see when I get there.

he must have had 80-100 anvils there it was so cool, turns out he is a blacksmith of 40 years and has a shop in Columbia and buys the anvils from all over the world. He bought mine in Germany. So mine is around 450# and has no markings on it but he figures its around 100 years old, and it still looks great, has a few nicks here and there but not bad and he was very nice since I drove so far he nocked $50 off so I got it for just a hair over $2 a pound. so here is what you all have been waiting for PICS...

in the back of my explorer:)

-

ya looks good that way also, ill let my mom decide which way she wants to do it

-

Wow nice job man, but I think the welds are off a little so you'll just have to send it to me and I'll ummm fix it... ya, that's what I'll do but it will take me a looooong time to do ;)

-

ya I know totally sucked but I figured out what I was doing wrong and fixed it so that's good.. got a couple more pics with better lighting

-

thank you frost :D

-

haven't been on in a while been letting my elbow heal, I over did it with a bad swing and killed it. but finally got back out in the shop and made some stuff for my mom. up first is a coat rack that I made. the scrools are not grate but I did make a jig to make them:)

then today I made my first dinner bell its a little off but its all good I like it

thats it for now but ill be making some more stuff for my family soon :)

-

i have my 2 burner economy forge from dimondback sitting on a wood bench i made, with some normal bricks under it and behind it when I dont need to put a long piece in it and it works fine haven't burnt up the table at all unless I drop hot steel on it :blink:

-

don't think the artificial sinew will get cut I jb welded it before i put the holes in for the sinew so there is space.. and if it dose get cut oh well I want to make another one anyway. I didn't put anything on the paracord that way it is still usable if i need to take it off for something, and there is a 2nd lair of paracord underneath with the threads taken out so if I take the top lair off there is still some grip to it.

-

so I have some coil springs laying around so I thought I would hammer out a knife. I also made a sheath but it was out of thin leather, it will work for now but ill make another one when I get some better leather. But I had a lot of fun making it, left all the hammer marks in it to give it some character. All in all I like it, and learned from it :)

-

looken good man. I think you should keep the pink just to be different

-

yes Dave it is, but no worries i fixed it before I put it up

-

ok cool

-

im going to have to try the leaf as a hook that sounds cool

-

thats cool good work. what size stock did you use?

-

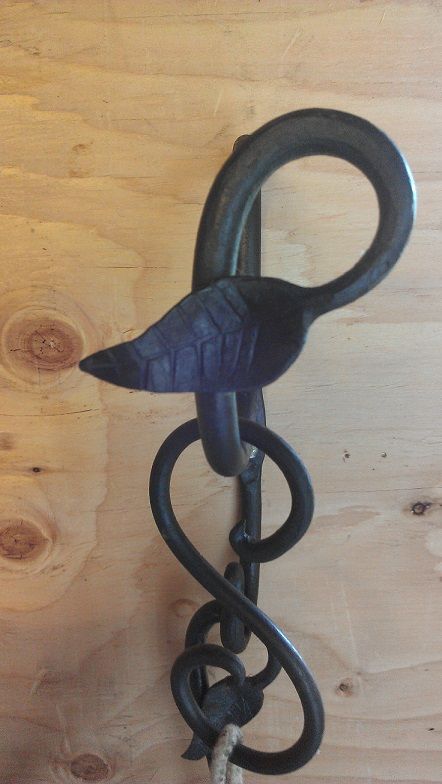

was out in the shop getting my hammer handles just right so I fired up the forge to test them out. Started making a leaf and was thinking about making it a key chain but instead I made it in to a hook :D 3/8" square

-

Ty guys for the kind words :D

-

the boss is 1x1/4 and the reins are 3/8" round so its at least the tallest part, and the rivet is 1/4 to match the thickness so i guess im kinda close to what you described I think

-

the reins are welded on so its probably week there anyway, the reason I went that route is because I hurt my elbow making my first pair. I will learn to make bolt head tongs and other tongs down the road but I needed tongs and there was no way i was going to spend 40$ a pair when I can make them, and I was able to do it without killing my arm so I can get my strength up.

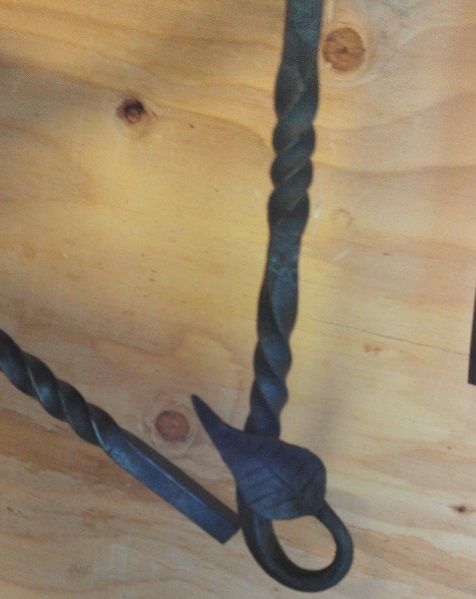

here are my first tongs, I hot punched these but didn't draw out the reins.

Lit the forge!

in Blacksmithing, General Discussion

Posted

oops double post