-

Posts

110 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by hiltsbilt

-

My bellows are big also, 4 feet wide and the piston box is like 18" square. Not too far off on some of the measurements I have seen but it works well and not hard to use. I do plan on making one at least half the size to use on a portable setup I would like to build.

-

Nice looking setup. I'll probably do a side draft in the future, if I can get a ladder tall enough to get on my roof lol.

-

That sounds cool, you have any pictures?

-

Okay, got the video up

-

Box bellows works great, even had my 5 year old helping me pump it. I already have a coal rake that I made forever ago

-

What did you do in the shop today?

hiltsbilt replied to Mark Ling's topic in Blacksmithing, General Discussion

Got to use my new coal forge today made up a fire poker (twist isn't the best, because I still need to remount my vice) and some hooks. -

Just Getting The Ball Rolling

hiltsbilt replied to Mulebrain's topic in Blacksmithing, General Discussion

Nice Find!! -

First thing made in the new forge, New fire poker. The twist isn't as nice as I wanted because my vice isn't remounted yet lol also recorded it, and when I'm done editing together the video ill post a link.

-

To extend on what frosty said, Japanese box bellows are easy to build as well, and are nice to use (its what I have). Mine are a little too big but not that far off from common measurements. I also agree with the others just build a forge, it will be more rewording and you can do it for a fraction of the price, and prices are crazy right now. There is a forge in my area that's like the bigger of the two you posted and he wants $1300 for it lol

-

I just meant the chimney was the wrong size, most people recommend 10" or bigger and straight out the roof. I'll probably be using mostly coal (I can get it 30min away), and use charcoal as a backup or just a change. Unfortunately, I didn't make anything, I was too tired. but I'm going to try to get some stuff done today. I have a coal rake, but I need a poker so I'll make that first, then ill make hooks for the doors, then a tong rack. I also still have to remount my vice and organize the area.

-

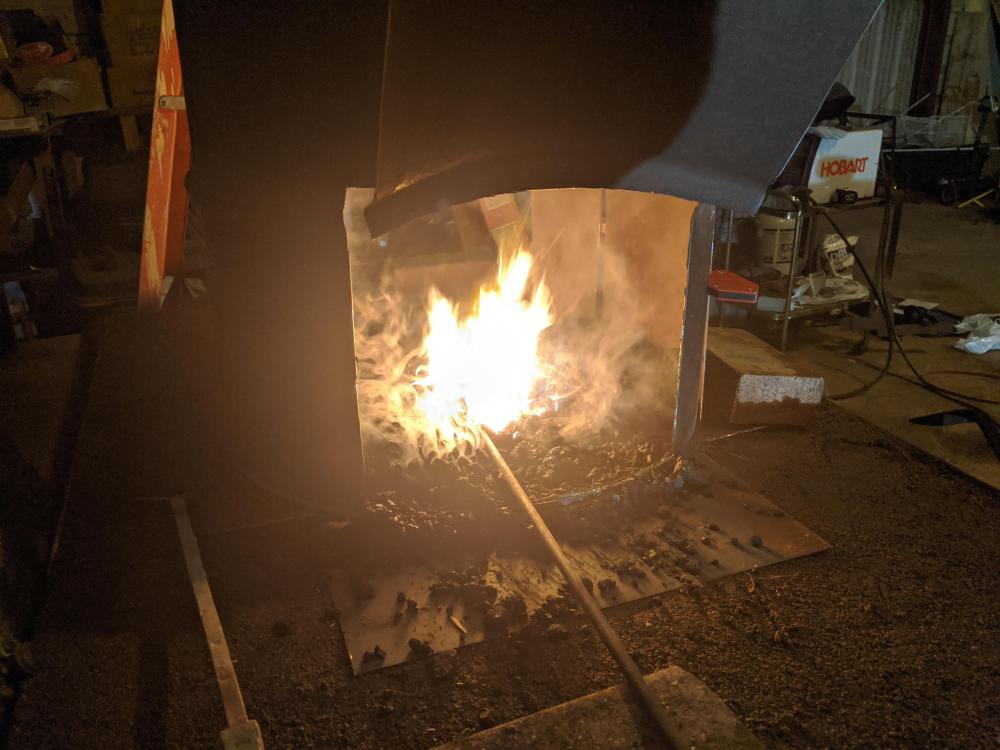

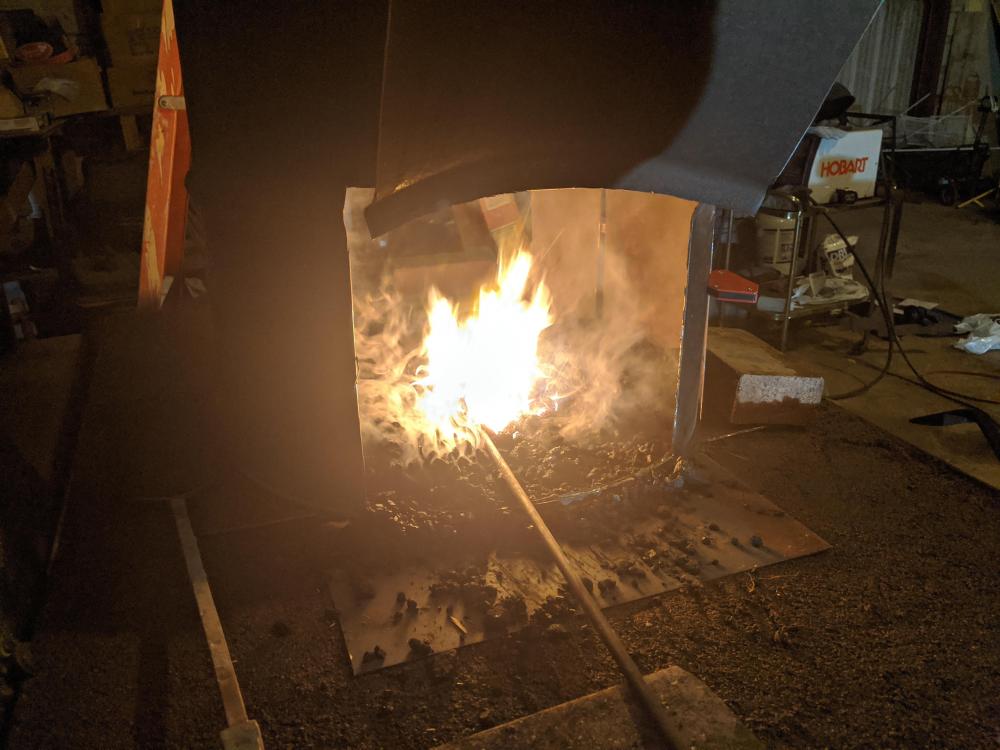

Finally got the forge going. It draws well despite doing everything wrong, 8" black pipe with two 45s and a 90 bend in it. I can close the whole thing up to warm up and prime the chimney so that helps. So happy to finally have it built, my little propane forge is limiting on what I can make. The first fire was just with some scrap wood.

-

on the bigger knifes I cut out the basic shape with an angle grinder then took then to the forge to refine the shape and forge the bevels. then when I annealed the blades I wire brushed them very well to clean them up a bit, after that i did a bet of rough grinding and then hardened and tempered the blades. next I took some 400 gret wet dry sand paper and with some water used it on the whole blade just to clean them up a little and give then the little shiny spots. But I do not smooth and grind the whole blade, only what is going to be sharped, because I like the rustic finish and being able to see the hammer marks looks cool.

-

Ya that part of my shop is not heated, you can see my breath in the video, but with the forge going and swinging the hammer only my feet are cold.

- 6 replies

-

- blacksmith

- youtube

-

(and 1 more)

Tagged with:

-

Thank you

- 6 replies

-

- blacksmith

- youtube

-

(and 1 more)

Tagged with:

-

Made a YouTube video of making some tongs, not a "how too" I'm not really at the stage where I think I can do a how too yet. Here it is https://youtu.be/IFV_1qNAy_U

- 6 replies

-

- blacksmith

- youtube

-

(and 1 more)

Tagged with:

-

I made some knifes and sheaths for my nephews for christmas. They are all mostly the same, just different color sheaths and paracord. I had only made 1 knife prior to making these 5 so they are a simple shape but thick and strong for whatever they want to do with them, and have a bushcraftish shape :-) The first picture is after they opened them, then the close ups are of the one I kept for myself. The last few Pics are of a smaller knife that is more suitable for my EDC, I'm not sure I like the shape but its comfortable to hold and works well, I also did not rough cut the shape, just through it in the forge and started hammering. All of the knifes are made of 1095. This was also my first time doing any leather work thats why i used rivets I could not get all the leather tools needed to do stitching.

-