-

Posts

90 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by dagr8tim

-

-

6 minutes ago, Daswulf said:

Dagr8tim, hope it works for ya. what kind of jeep?

The brake parts will most likely end up on my 1997 Jeep Cherokee. The parts physically fit the rim (the biggest fear). Now I just need to see if I can bolt the brackets to the Jeep axle (looking very promising).

-

Picked up an early 2000's Dodge minivan rear axle. The axle will go under a 4x6 utility trailer I have to convert it to 5x4.5 (same as my Jeeps), and hopefully the rear disk brake assembly will end up on one of my Jeeps as a rear disk conversion.

$50, and about an hour and a half of my time to pick it up. -

I think I know what you are doing in terms of mods. I'm not going to go into details. I'll just say the whole process scares me.

Back to the original post. Non strut shocks tend to not be under so much pressure if you are after the hardened polished shaft. -

26 minutes ago, SmoothBore said:

For what it's worth .....

Horror Freight has the screw type strut spring compressors, ... for $15.99.

I've used those before and they are scary.

I ended up having to cut one off of a Jeep because there wasn't room to unscrew it after getting the coil in place. -

39 minutes ago, Dave51B said:

Dagr8tim, the jack was just going to be tossed in the scrap, so I had to take it to save it...I'm not sure you can tell from the pic, but there is a foot on the bottom of the jack to lift low to the ground. I think the little forge will be handy to travel with. Life is Good Dave

Looks good.

-

5 hours ago, Dave51B said:

Granted, I don't know much about the jack, but if I saw that somewhere, I would assume the handle was original.

I need to expand where I search, I cannot for the life of me find a little forge like that, but not for lack of trying. -

46 minutes ago, Michael Cochran said:

I will definitely not be taking these apart myself nor will i buy the tools to do it myself in the future. I looked at the cheaper ones and the make me nervous and I looked at them wall mount ones and they are a bit pricey for an item that I may only use a few times ever. The cost for them is still cheaper than the hospital bills I'd get if I got hit by one of these springs but I'll make nice with one of the local mechanics and bring him some little things for helping me out each time.

For the sake of discussion have a seen a few suggestions online that people share for removing the springs and I plan on starting a topic in the safety forum when I do some more research showing the dangers involved with haphazard setups.

I want to be sure everyone knows I do appreciate the concern for my safety. It feels good to know there are still some genuinely caring people left in this world. I sometimes forget that there are.

I agree with your decision 100%.

That being said, *IF* this was something I was doing on even a simi regular basis, I think I could come up with a safer alternative.

Take 2 or 3 of these and mount then vertically on a wall. Then build a floor plate with a hold in the center for the strut to hang down through. Then a top plate that is keyed into "rails" on the wall. Then two chunks of threaded rod and some nuts to do the compression.

Then again, when my wife's car needed new struts and had over 100,000 miles on it. I just ordered 4 "quick struts" that were the whole assembly. No need to swap parts or disassemble anything. -

3 hours ago, Glenn said:

Garages have a wall mounted clamping device for SAFELY removing the spring from the strut. It is under compression and can hurt you when it is being released.

I've done it with other cheap devices I have bought for coil springs. It's sketchy and scares the xxxx out of me.

-

Dagr8tim in Columbus Ohio go talk with Adlai and Terry over at the Idea Foundry about forges and smithing; tell them that Thomas Powers sent you. (Ask Adlai about the time he made a forge from a semi brakedrum!) Start going to the SOFA meetings---we used to carpool from Columbus to Troy to hold down the cost of going.

Thomas, I took a blacksmithing class at CIF many years ago, and Adlai is the one that got me interested in smiting. Infect he lives about a mile and a half from me.

If you are talking about the Terry, I am thinking of. I used to work with him. He talked me through setting up my aluminum smelting/melting furnace. -

Okay stupid question alert... I am brand new to researching making a forge .. I am more of a visual learner so reading all these posts sometimes leaves my eyes crossed and I gain little .. in regards to the sink forge .. I plan on starting with a small forge to play with and learn the attributes of the metal and etc .. was thinking of crafting chisels and other small simple shaped tools and the like .. can I not just clean up the sink and use refractory cement to line the whole thing .. or am I thinking too simple? Again .. just beginning and intending on starting out small.

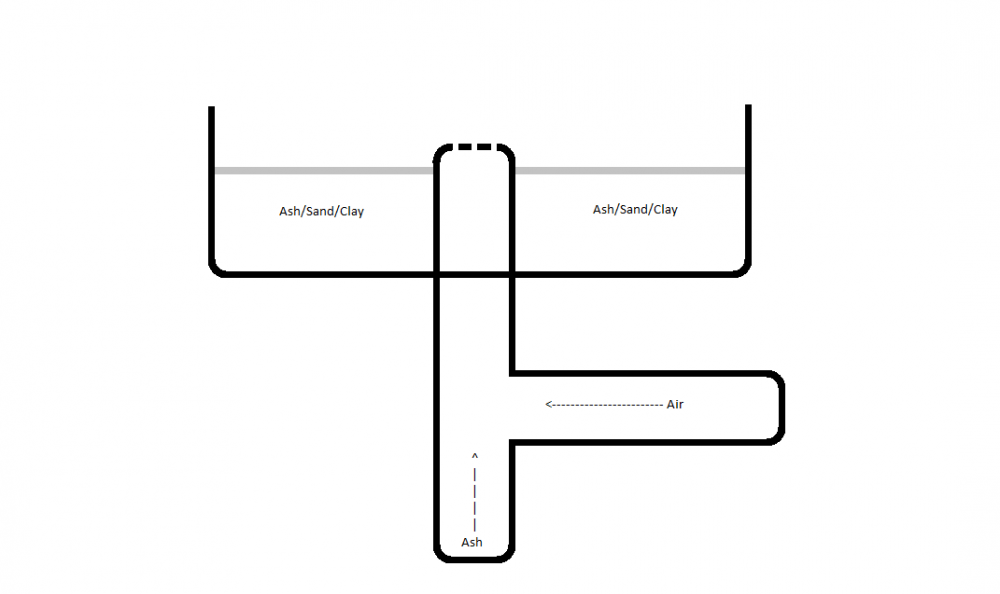

I'm by no means an expert, but this is what I am picturing in my minds eye. A simple angle iron box to sit it on and you're cooking. Here's a simple (not to scale) diagram of my understanding of the setup.

If I'm missing anything, hopefully somebody with more experience will set me straight. -

I'm not opposed to coal. I just have no experience with it. I like the sand idea. That's sorta what I was getting at with the lava rock question.

-

Sink works fine if you do a nice V cut on opposing sides so you can get long stock into the hotspot. Building up the bottom with creek clay and ashes helps too; but makes it much heavier to move. What are you planning to fuel it with---Coal or Charcoal?

Charcoal.

I've seen it done before and have a couple sinks layin around but have yet to try it. http://www.popularmechanics.com/home/how-to-plans/how-to/a4087/how-to-make-a-forge/

Thanks, that's alot of what I was thinking. I've done brake drum forges in the past. I'm just looking for something a bit bigger.

-

Do not over think simple. A hole in the ground has worked for years. Later they put the hole in the ground waist high so you did not have to squat or bend over.

Do a search on the 55 Forge. Quick, easy and fast to build and it can be modified in many ways.

Thanks for the sanity check. I just ended up with the sink and faucet for $2 and was looking for something to do with this chunk of stainless steel.

-

While at a yard sale yesterday I picked up a stainless double tub kitchen sink. I was considering doing a hybrid brake drum forge and wanted to know if anyone has ever done this or has any ever seen anything like this. I know the tub is going to get hot and lose heat fast. I was considering building a metal stand out of some angle iron and lining it with some form of insulation, and then rivet some like 20 gauge sheet metal on the outside.

I'm playing with either cutting the tub down to not make it so deep, or finding something I could fill in the tub about halfway to take up space. I was wondering if something like lava rocks would work if I should stack some fire bricks in it.

My other idea was to use the other tub for the start of a hood for the forge.

-

Not to drag up an old topic, but I figured it was better than starting another topic with the same basic question.

I'm trying to come up with a refractory recipe that will work for a charcoal/coal fire initially and eventually I want to get to propane. The working plan is 10 pounds of bentonite as a binding agent and 50 pounds of fireclay. I'm wondering if I need any sand in the mixture. I know everybody has a prefered DIY refractory formula, and most DIY solutions are not as great as commercial ones.This is a small forge that's made out of an old Balloon Time Helium tank (slightly smaller than a 20 # propane tank). I'm hoping to avoid using sand, but if I have to use sand, using it as a filler material.

-

Picked up a set of S-10 leaf springs as part of some horse trading.

-

I'm not sure if this technically counts. But it literally followed me home this morning.

-

One of the guys who owned a drilling company(drilling for oil)used to buy a new Caddy every couple years and have it delivered to a body shop that would turn it into an El Camino.

You`d see it by his rigs with drilling tools in the bed.I want to say it was King drilling but not sure,it was a while back.

The process wouldn't be too different than the way they cut down Caddy's to make hearses. -

Are you guys sure it's a plating? I thought Chrome Vanadium was an alloy of steel. It also appears that knives are indeed made out of it.

http://www.ehow.com/list_6130902_properties-chrome-vanadium.html -

I've got this old 1/2 inch drive 15 inch long ratchet that I managed to destroy this weekend. I'm wondering if I could forge the handle into something. Mainly I'm worried if there are any health and safety issues with heating the metal.

I was thinking the handle would make a great handle for a knife, then forge the blade out of the shaft of the ratchet.

Here's the ratchet in question.

-

Hmmm. I have a couple of old battery drill chargers . Wonder if one would work as a DC power supply for electrolytic rust removal.

I typically use wall warts with the transformers on the plug. Normally I work with under an amp because I'm doing small things. You'll want to increase the amperage as you get into bigger parts. -

Well, since everyone else gave the Smithin' uses, there are loads of other good things to use fireplace ashes for:

Ten uses for Wood Ashes

Of course, you can also use it in the old Outhouse instead of lime.

Regards,

Tim

Good list. We also used to to shine up the metal runners on our sleds when I was a kid. -

Thanx for the compliments.

It's pretty much free standing. I wrapped the base in such a way as to sit level. There are basically just a couple oversized steel "tent" stakes holding it to the ground.

I didn't wanna cement it in, due to "break away" laws. If a car hits it, it has to be able to give. Last thing I need it to be sued because someone runs into it and breaks a nail, or something equally retarded.

Really, I probably would have sunk 3 concrete blocks in the ground and then used a thinner chain or wire to attach it to the blocks. You could also do something similar with a concrete pad. Just use something significantly weaker than the chain and the bridge and it will break before anything else does. Atleast IMHO. -

So today I cleaned out my fireplace, and I'm left with a 5 gallon bucket of wood ash. I'm wondering if it's usable for forging, and if I should maybe sift it before using it or what to do with it. I didn't burn all the wood that produced the ash, so there could be ash from some of those fireplace logs (wax and sawdust), or even parts of furniture.

Before I go any further, I'm wondering if it's worth messing with or if I should dump it on the ash pile behind the garage.

It followed me home

in Blacksmithing, General Discussion

Posted

Thanks for the tip. Once I get the brackets stripped off, I'll go through the axle well. It seems that the axle is a tube that then has a jog on both ends to offset the hub assemblies From what little I looked at it before the rain came in, it looks like the tube is a straight shot with both ends open.

It'll probably get atleast wire wheeled and rattle caned after I get it cleaned up. I'll have a chance to inspect it carefully.