-

Posts

1,095 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Stormcrow

-

-

Frosty - Nothing too exciting. "Gunnhildita" is intended to be a smaller version of "Gunnhilda" built for Tobin's use. San Antonio is heavily Hispanic, and -ita is a Spanish feminine suffix for "little", which can also be an affectionate term.

One of the nice things about the "Rusty"-style guided helve hammers is that the design can be easily scaled up and down between a 15 lb ram (the original Rusty) and about a 100 lb ram (Gunnhilda). Gunnhildita would be closer to the original Rusty size.

-

Hah!

The Dispos-A-Hammer is something we're building for Tobin as a stopgap solution to him not having a power hammer. We actually wanted to build a smaller guided helve hammer (dubbed "Gunnhildita"), but after spending a lot of time sorting out what material we had on hand and how to design it (I voted for slightly more complicated but more versatile, Tobin voted for simple and get it done), we struck on the plan of an unguided helve hammer as a temporary solution. The plan was to get the Dispos-A-Hammer going quickly, then later down the road use components such as the tire clutch and the pivot, to build Gunnhildita.

And then for some reason we (by which I mean Tobin) decided to make the column supporting the tire clutch out of wood instead of steel tubing as we had already planned (and had material for). And it flexed way too much, as I was afraid it would. That was about the time we had a knifemaker gathering out at my shop, and then Tobin was ill for a long time with a respiratory infection and I was busy with Forged in Fire. So it hasn't gotten finished yet.

But we'll shoot some video and pictures when it is ready to go. Tobin is going to have a table at the Blade Show for the first time this year, and still needs a power hammer, so maybe it won't be too much longer.

-

Thank you!

This is the last of my FiF stuff. It's dominated my week, but now I need to get back to working on Blade Show inventory.

A washed-out look at the push knives I did for the first challenge. They can actually be seen better in the reflections.

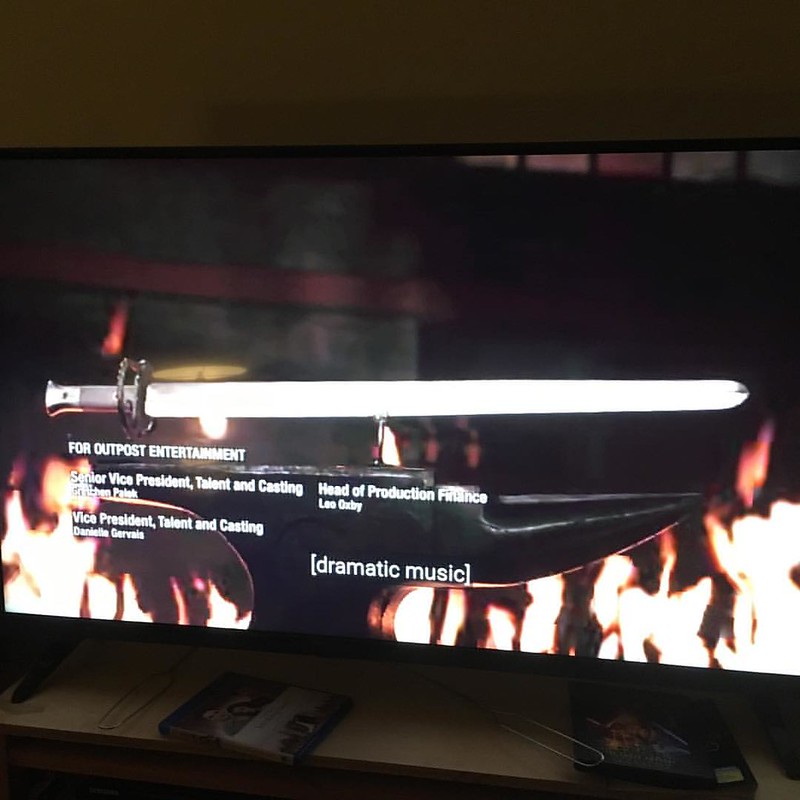

The katzbalger in its hideous glory:

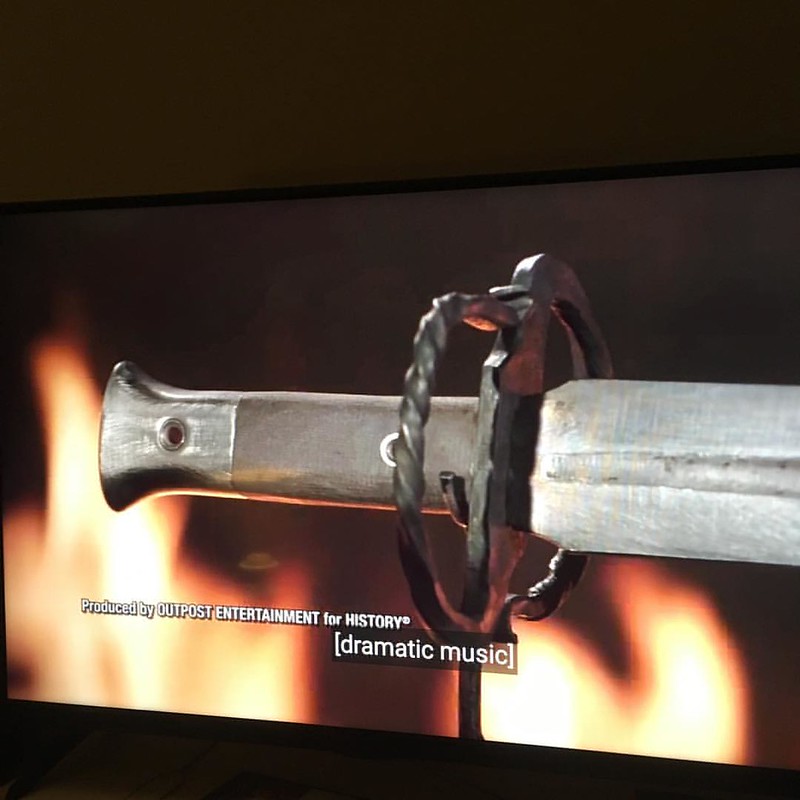

My second take on the guard. Didn't like how the first one fit, so abandoned it before I finished out the quillions.

And my second take on the handle since I ground through the side into the channel for the tang on the last day. So many things had to be done several times on this that I named it "der doppleschwert". The pommel was forged from a piece of pipe with the end cap oxy/acetylene welded on. The TeroTuf of the handle fits down into the pommel and the flared tube rivet goes through pommel, TeroTuf, and tang.

And finally, a YouTube video featuring myself and fellow FiF champion Tobin Nieto (season 2, episode 8, Cutlass) reflecting on the show, our experiences with it, and answering common questions and criticisms. It's as long as an episode of FiF, but I think it's both entertaining and informative.

-

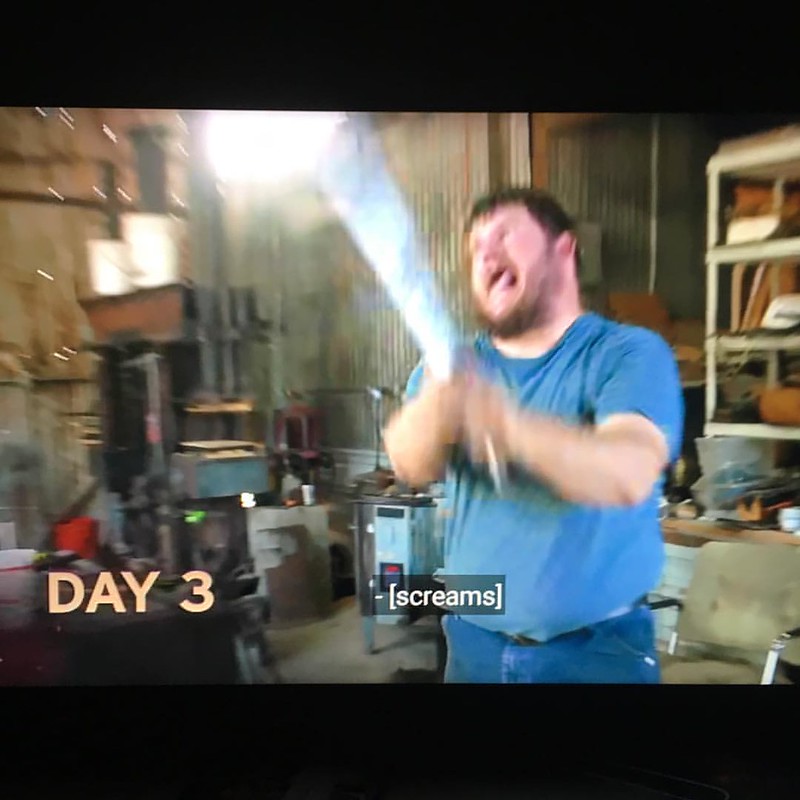

This is seriously the best part of the episode. I laugh to the point of tears every time. I had forgotten I did this until I saw it on international television.

What got left out was after I took a bite of watermelon and said this, I followed up with, "...and sharpening oil."

-

Frosty - It was Jesse Howard. He's ok. Several people have asked about him, so I asked what he'd like me to say, and it is a pre-existing heart condition that he didn't know he had until he started feeling dizzy on the show. It was triggered by the stress, including heat and lack of sleep. It's a good thing he stopped and sat down when he did!

SLAG - I found some pics and will try to get them posted up tonight or tomorrow.

On the question of time during the five days at home, you have 5 hours on the first day and 10 hours on the others.

-

Thanks, guys!

#awesomeandhandsome

#snackbreak

I'm glad we had the challenges we did. They were not easy by any means, but they were doable.

Rashelle -You fought hard for it and it was a close race!

John - It was my second push knife that didn't cut a lot on the sandbag, not Paul's. I had about two minutes before time was up where I could have worked the edge some more, and I had to decide whether to try to get it sharper, or risk messing up the edge I had. Probably should have gone back to the whet stone during that time, but hindsight is 20/20.

Nate - It was very difficult *not* to overheat with the forges. I cut off the center burner and turned down the other two, used a pipe to muffle the heat, and it still was way hot. That's why I went to the torch to harden. Probably should have cut the two outside burners and turned the middle one down. Watch the show for a while and you'll see a lot of folks quenching with steel that's way too hot.

SLAG - I don't have any pics, but I'll dig around and see if I can find some on teh Interwebz.

-

-

Tomorrow night! (Tuesday, April 18, 8:00 CST)

Here's the episode description:

"For the first time ever, the competitors are challenged with creating not one, but two blades in the first round. With double the pressure and double the work, the bladesmiths are pushed to their limits, which leads to another first–a hospital trip. After a grueling second round, the two remaining smiths have just five days to create an iconic 15th century combat sword–the Katzbalger. Which bladesmith has what it takes to burn through the obstacles in their way and become the next Forged in Fire champion?" -

I'm sure looking forward to seeing us on TV, Rashelle. I think it's going to be an entertaining episode!

Weren't no part of it that was easy, for sure! But definitely worth doing.

-

Thomas - It was over on Keenjunk.

It's a small world. Rashelle knows Arnon, who made the dagger that my buddy Tobin used to forge his blade in the first round challenge for his episode.

-

One of the other contestants in my episode is also on Iforgeiron. She's to my right, second from the left in the picture.

-

Forsty - We had the opportunity to change the anvil orientation, but I work from both sides of my anvil so I didn't bother.

They're now showing commercials for my episode (next Tuesday, 8:00 CST), and it's interesting to see myself on the TV screen. The cuts are edited so quickly, that by the time I realize I'm looking at myself, I'm already off the screen.

It should be an entertaining episode.

-

New season starts this week.

And on the 18th:

-

New season starts this week.

And on the 18th:

-

Such clean, meticulous craftsmanship, as always. And "Horn Mohawk" sounds like it should be the name of a death metal band.

-

That is so cool!

-

Some recently finished tantos. All are 80CrV22, with paracord wraps over neoprene hardened with West System marine epoxy, with Kydex sheaths.

This black one was a commission, while the tan one will be on one of my tables at the Blade Show. Blades are around 7".

This o-tanto and smaller, stabbity slicety tanto were a commissioned pair by a son for himself and his father. The o-tanto is about a 14" blade, and the other is about 7 1/2".

The stabbity slicety tanto is about as narrow a point as I can recall doing on a blade!

The son decided he wanted a retention strap added to his o-tanto as a belt-and-suspenders insurance policy to keep it secured while it rides on a pack.

-

Here are a couple of camp bolos that went out to customers recently. Both of these started out as demonstration pieces, showing how I use the dies on my power hammer to forge blades. Neither one of the customers who ended up with them had me build sheaths for them. The blades are a little over 12" long, with false edges on top.

This first one was for the first STAB (South Texas Association of Bladeslingers) get-together out at my shop back at the end of January, forged from 1084. I finished it out with tan over black paracord on top of a neoprene foundation.

The second was forged from 5160 as a demonstration for a fellow who came to my shop to study my home-brewed guided helve power hammer to help build his own. He ended up buying the demo blade from me, and I finished it out in black over black paracord over neoprene.

-

This tends to get called either a raised clip or a harpoon point. It's visually striking and can be quite aggressive looking, and also makes a wider point (and therefore wound channel) for stabbing while keeping the overall blade width and weight down.

I'd say for most knives, aesthetics is the main reason for such.

-

Nicely done!

-

Joerg is a hoot and a half. I enjoyed the opportunity to build a blade for him, and am glad to see him bring it out and cut stuff with it again.

He's done some neat stuff with compressed air guns lately.

-

You did some beautiful work here!

-

Some of y'all may (or may not) recall a few years ago I built an 18" sword blade for Joerg Sprave, the German mad genius of creative and deadly slingshots and other unconventional weapons. He built a handle for the blade that (of course) incorporated a slingshot.

http://www.youtube.com/watch?v=lWI0jqsW4Cc

I was pleasantly surprised to see today that he had brought the slingsword back out, as a basis of comparison for a wooden sword he had made from European dogwood, the hardest wood that grows in his area. The slingsword shows up just before 8:00 in the video.

http://www.youtube.com/watch?v=GCjXZk-vzvg

As far as I'm aware, this is the first time a blade of mine has been used on a tatami mat cut. His comment: "The tatami felt like NOTHING AT ALL when I attacked it with your blade... great work for sure." :cool:

-

Thanks, guys!

Blademithing series on History channel

in Knife Making

Posted

For those of y'all interested in the Dispos-A-Hammer in the video I posted, Tobin finished it up at his new shop, tested it, found it wanting, and cannibalized it into a block anvil and a post vise stand. I never got to see it running for reals, but apparently it was not hitting hard enough to be worthwhile. Tobin has a manufactured hammer on order that should be here this summer. The Dispos-A-Hammer was always intended to be a temporary solution.