Paradigm11

Members-

Posts

35 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Paradigm11

-

Yeah, we'll see. I'm took extra care to super reinforce the chimney right before the penetration so the biggest risk is probably the twist lock coming undone, but that's heat taped and clamped so I'm pretty confident I'll be fine. Like I said in other comments, the wind in that area is pretty seriously negated due to various barriers in the area. I can leave an un-secured tarp on the ground in that area on a windy day and it won't move.

-

Chimney is up! Now THAT was a pain. It's a little janky and I ended up using a roof support kit to hold it in place because I couldn't find the part I needed for a reasonable price. As with all of this thing, it's not the prettiest but it meets all the clearance requirements. Hopefully I'll be done with everything but a couple more boards and more gravel this weekend. Chimney stack is about 10' not including the cap. The T is something I'm trying in the hopes that the turbulence of the capped end will kind of work like a smoke shelf.

-

A couple more pictures! Winter is coming and it's been a really busy few weeks. Got the roof flashing on (waiting for another warm day to put on the actual roofing). Big step today was to have enough coverage to be comfortable bringing my forge out and starting to figure out the positioning. Had a REALLY windy day and it didn't budge despite all the wind catching in that back corner so I'm pretty confident I'll be all set with it "floating." After putting down those pavers I really like how they look so once I get the rest of my gravel I'll probably slowly make most of the floor those. $6 each adds up fast, but there's no rush. Still need to level it off better, this was me getting a position to line up the chimney bracing. As you can see in one of the pics, I've got a lot of wood to stack and I had foolishly blocked my shelter with all of the building supplies so its it's going to be a busy week!

-

Yeah, turns out I didn't know him as well as I thought I did (in a good way). Pretty cool thing I learned today after talking to my dad is that he worked at the Portsmouth Naval Shipyard as a welder in the 40s right after WW2. The way he talked about woodworking I thought he'd been a logger / millyard guy like my grandfather (Google Berlin NH). Turns out it was just a hobby and he was a metalworker!

-

Haven't seen it in person yet, as I'm travelling for work but my dad said he found his uncle's old vise in the basement the other day and asked if I wanted it. To which, I obviously said yes. Looks like it's in really nice shape. My great uncle was awesome, so it's not only a cool find but fairly sentimental. I had no idea he did anything but wood working.

-

In my area we don't need a permit for any accessory building under 200 sq ft so long as there isn't a solid foundation. Concrete pilons / sonotubes are allowed, but the effort of digging that deep isn't practical without machinery. Regarding the wind thing, I'm not sure I have the right way to explain it. Basically, its a wind dead-zone. I have some pictures from winter I can try to find that kind of illustrates the point. There are no requirements for it to be firmly attached to the ground, but I do intend to do some anchoring with cable and ground anchors because it's cheap and practical.

-

Appreciate the replies, as always! I think I may try it without the fan for starters. We're getting close to done now. Got some rough cut pine for $0.85 a board foot and I'm nailing that up as siding. Looks really nice if you're into the rustic look, imo. Getting a truckload of fill soil this week to fill in that back corner, it's all level I swear! Waiting for a couple dry days in a row to get the water barrier up. I'm very glad I decide to build this myself. Costs keep climbing but it's still been cheaper than buying one and it's nice to learn as I go. Still can't believe I built this. Fitting the top board (not pictured) was a bit of a bear. The 10' high one is going to be stressful.

-

Ok I think I've gotten the information I need. Final question regarding the chimney. I know 8" is on the small side of recommended already, and if you look at the pics of the forge you can see I'll need to do an immediate right angle out of it to go straight up, which I know is generally not recommended for creating a good draw. Since it's directly at the entrance to the hood will the bend really cause that much of an issue? The chimney is probably going to be around 12' tall after the hood. Probably will be doing the T right at the hood that Frosty suggested.

-

I actually talked to the fire chief already and he said just to follow the manufacturer instructions and don't store accelerants in the shed. I've also read that the fumes cool quickly, but fire codes don't really care. The pipes are double wall insulated, yeah. I was kind of considering just doing the required clearance of the non-insulated because I have the room. The 10" pipe thing sounds clever, I may do that. Thanks for the advice as always.

-

Ok, so I'm a little stuck on the requirements for penetrating a roof (went that way after some thinking). I purchased a supervent ceiling support kit from Lowe's which is for 8" ID double walled insulated stove pipe (more on the 8" thing in a bit) which requires 2" clearance from combustibles. No problem there. Roof Flashing Assembly (including Storm Collar) is required when the chimney penetrates a roof. I've got that, no problem either. Here's where the confusion comes in: Rafter Radiation Shield: Required when the chimney is enclosed immediately below the roof (I don't have this). Bit in the section on RRS it says the following: A Rafter Radiation Shield (RRS) must be installed where the chimney is nclosed immediately below the roof line. An example of this is when the attic space of a house is being used as living space (ie. bedroom, guestroom etc.). This, to me, seems to imply it's only required in living spaces. Here are some pics, we got the plywood up yesterday: here is the spot where I plan to put my forge with the chimney going straight up and out. View of the section it will go through (still some minor framing to do, was waiting to do it while framing the chimney support). I believe I should be fine with just the roof parts and the ceiling support, but wanted to run it by everyone to make sure I wasn't crazy. Regarding the 8" thing now, that's just the size of the hood I have. I bought my forge off of Facebook marketplace a few years ago and the guy who had it was using it fine in a much smaller shop than mine. Here are some pics of that: Firepot dimensions are 8" x 10" and 6" deep. Exit is 8" Hood detaches so I moved it around to find if one way worked better than the other. Can see where I burned the paint with a bad config / windy day tried it without a chimney in my yard). Need to repaint it. I apologize for the lengthy post. Really into this project right now.

-

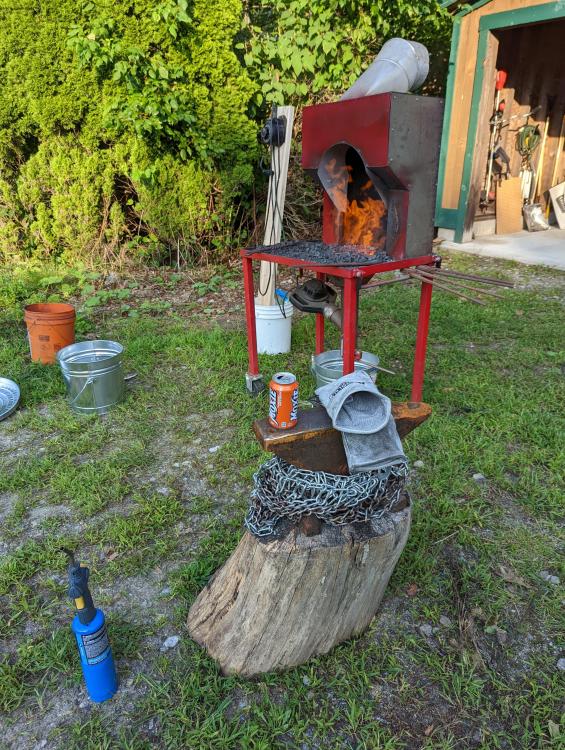

Apologies for the double post but for whatever reason I can't find the edit button to my previous comment and I actually do have a question: For the roof I'm planning on just doing 1/2" plywood and corrugated metal / plastic on top. My question is whether or not I should go for metal / use insulation or heat tape for the chimney? I've got a coal forge and the chimney will likely be pretty tall. A minimum of 8 feet vertical gain. I've attached a picture of my my current setup that I drag out whenever I do anything. Not anything special. I plan to do take that chimney and go straight up through the roof and use high temp caulk for the sealant.

-

The recommendation was for swinging it up. I'm not planning on doing that currently, but I've got an idea of how I would if I ever choose to change it. Nice thing about building my own shed is that I know for certain what I can change without goofing it up too bad. Big reason I used nails instead of screws for the stuff that wasn't critical to the structural integrity. I do plan on making a big ole door, though. My first project in the new area is to make hardware to hang a big, heavy door in that area in the left where the planks at ~5' are missing.

-

Just posting an update to let everyone know I hadn't given up! Coming up quite nicely and I think I'll have it done for under $1000 thanks for a bunch of scraps I've gathered. First time building any structure so it's not the prettiest, but it's square and it's held my 250kb weight as I've clambered around. 4 more 2x10's for the roof and then I can slap a top on it and nail some old barn wood to the outside. I plan to do corrugated metal on the inside with a sand/gravel floor. Last step will be building out a retaining wall in the back to level the actual ground instead of just the key points.

-

I follow a youtube guy that goes by Black Bear Forge and love his stuff. Recently I was watching a video where he espouses the reasons to own a post vise, I've got a big ole antique vise I got out of a barn sale years ago and it does a great job. Big, heavy thing. The advice on how the floating mechanism is preferred vs the screw / machinist vise because of the possibility of heavy blows torqueing the screw out of alignment makes sense to me. I'm currently happy with my vise, but I'm curious if people have noticed significantly different quality of life between one or the other. Constantly on the lookout for them in my area, but as you might expect the market for heavy duty post vises is a fairly small one.

-

Yup, I'm avid skier, snowmobiler and general lover of snow. Very familiar with it's risks. NH doesn't get the snow that the west or Buffalo gets, but we're good for some big storms. I'm taking the advice of a steeper slope on the roof, though I'm not too worried. My carport has a pretty gentle angle and handles the snow fine. I've gone with the wood build because I like having a DIY project. I'm taking plenty of photos so I'll share a full album when I'm done. I appreciate all the information and discussion, it's a big part of the fun!