Iron Fangs

Members-

Posts

165 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Iron Fangs

-

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

Thanks to Daswulf (again. Thank you very much) I have been able to get my hands on a proper anvil stand and a forge that won't crumble when I build a fire in it, today I added a pitchel hole to the anvil stand with a little improv -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

External? My plan was internal frame like a canopy tent, so more external like a camping tent? -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

I'm going to try my first plan and just angle the roof a bit more, if it proves to not be stable then I've learned a lesson. And if it works then good! -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

Yeah, I was originally going for a Baker tent set up, the amount I bought would have probably worked for that -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

I'll look around for some, I always get home after dark on weekdays -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

I'll put in the extra work then, PA has no shortage of Maple trees -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

I'm sure he has been told once or twice? I have (roughly) 160 square feet of Canvas sheet, and I am now going to need to source poles, my goal is cheap and effective, and my options are PVC pipe and cut saplings (which are free but time consuming to fine proper candidates that are legal to cut down) -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

An interesting idea, seems like it would be more simple to construct and a bit more efficient too maybe? -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

I agree, that's why I am putting so much emphasis on it being able to be taken down in the design, until I actually own my property and can build a permanent structure that will hold up to wind and snow (saw a lovely Gazebo that would make a nice outdoor smithy yesterday) a well supported pop-up is my best bet. Yo help with the snow accumulation my plan is to make one side 2 feet higher than the other with a slope to encourage it to slide off (not going to be perfect but hey, I'm not the carpenter my dad was) That said, I will gladly take some advice or design recommendations! -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

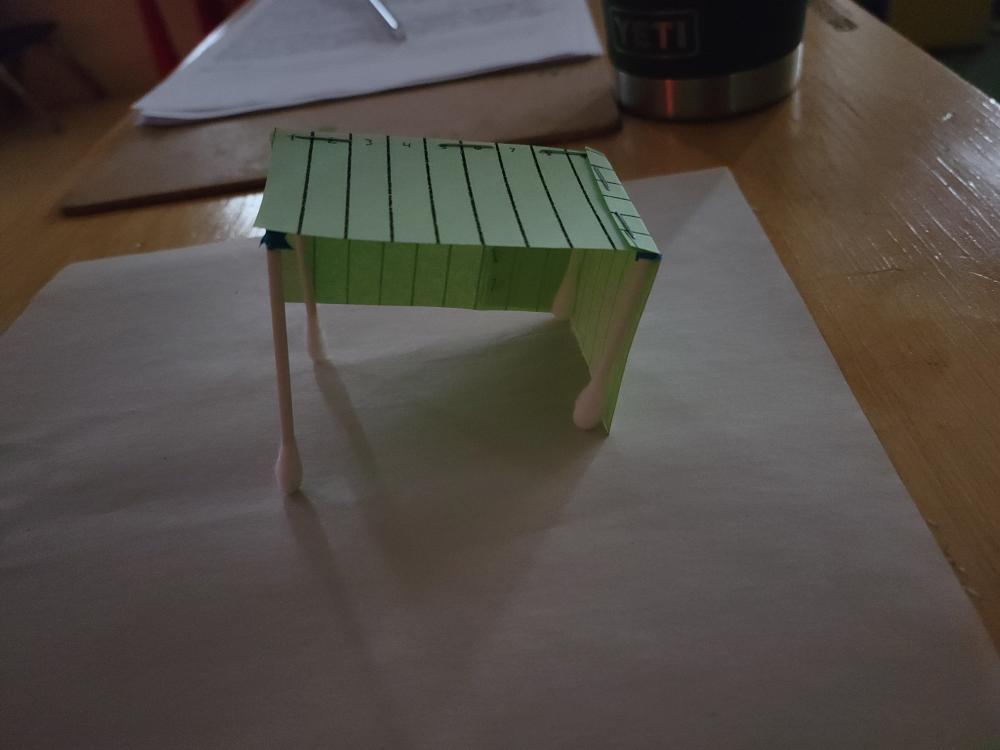

Update: I made a small paper model of my idea and figured out how I am going to stabilize it and keep it portable, attach brackets to the poles and fashion 3 removable horizontal support beams to keep it upright -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

I got some Canvas, four 6'x9' sheets, my intention is to use one as a roof, and sew two of them as walls to leave walls open for ventilation, my idea is to make a sloped roof with the high side being 8' and the low side being 6', and I'm thinking I'll need to cut saplings so thst I have two 8', two 7', and two 6' to keep it stable, with some creating sewing and using the fourth sheet to patch where needed to keep it together I should have myself a nice little pop up tent I can take down in extreme weather. I'm basing my design off a Baker tent setup -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

Speaking of books I just picked up "the Backyard Blacksmith" by Lorelei Sims and have been reading through it -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

I'm moreso using the suggestion of materials and trying to make myself a nice little pop-up shop I can stuff in the shed when I'm expecting a blizzard or thunderstorm that would blow my setup halfway across the greater Pittsburgh area, some saplings as tent posts due to how many Maple trees like to spring up around my area. The canvas to keep the rain and snow off my hearth, and probably some sort of makeshift foot on the poles to help keep it stable, I got some sandbags I can weigh the posts down with It's also worth mentioning that where I'll be doing most of my forging is several hundred feet above the nearest body of water -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

On another note, I am going to assemble myself a smithy tent because i am tired of rain, I think I'll be using the example set by Jake Pogrebinsky in another thread using a 15x12 canvas sheet and a few saplings -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

And there solves a mystery from my childhood -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

Oh, alright, that's more simple than I thought, well. Simple to conceptualize, not about to try it at home, not my department (anymore!) -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

I have seen the term "Die Cast" numerous times since I was a kid, mostly printed in nice big letters on hot wheels cars as a special feature in some design series, what is Die Cast? And is this referring to steel, cast iron, or something completely different like aluminum? -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

As promised yesterday I retested the pickaxe and compared it to that anchor, and I believe I was mistaken, looking again that pickaxe is definetly less than 2% carbon -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

Happy new year everyone, hope it's iron clad! -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

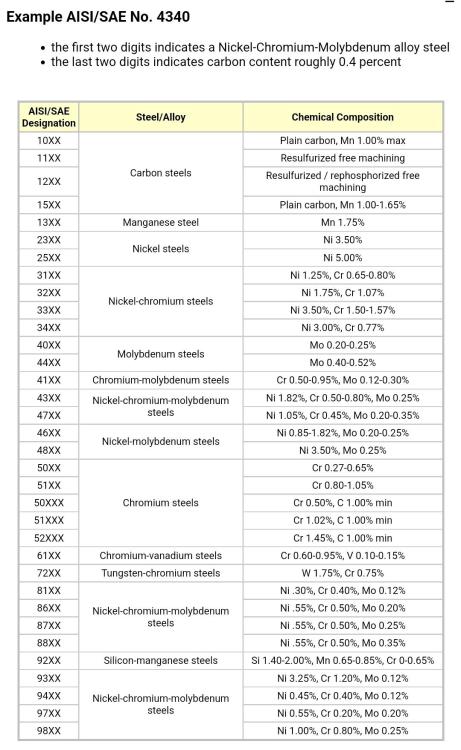

In regards to the steels in the 1000 digits, I'm not sure what these numbers mean? Is it a direct correlation to the amount of carbon? Because I've also seen in the 2000 and 3000 digits, I'm not trying to get a full understanding on the ins and outs of metallurgy on this thread (there are books Thomaspowers has recommended on several other threads on that) just a reference to help me understand a little better Is this chart a good reference? -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

Still seems like a good place to start, I recall reading in a thread that a nice mild steel ingot would make an 8th century blacksmiths head spin with delight due to the quality compared to their pattern welded steel and wrought iron, just gives me more to play with right? -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

That was a lot of info. But I'm assuming number after the listed part in the first paragraph listing the junkyard steel parts is the grade? As in "Hay Rake Teeth" was grade 1095 and "Axels" was 1040? This is example is from the second line of the first "table" -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

Can I get a thread name or link for that? -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

I'll keep my eye out for that stuff when I go! -

New and looking for advice

Iron Fangs replied to Iron Fangs's topic in Blacksmithing, General Discussion

I'll bring a selection of my stock, I'm interested in what those gears I have are made of, and I'm also making plans to go to a junk yard with my dad-in-law and brother, any parts I should target when I go?