Jim Foster

-

Posts

34 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Jim Foster

-

-

6 hours ago, Nodebt said:

Slag makes short work out of toe jambs!

Thanks for the photos. Nice. I'll look at them for a while before asking a dumb question or two. It appears to me it clamps to the ways. I have one my grandpa made himself, but it clamps in the compound rest. Again thanks for posting the pix.

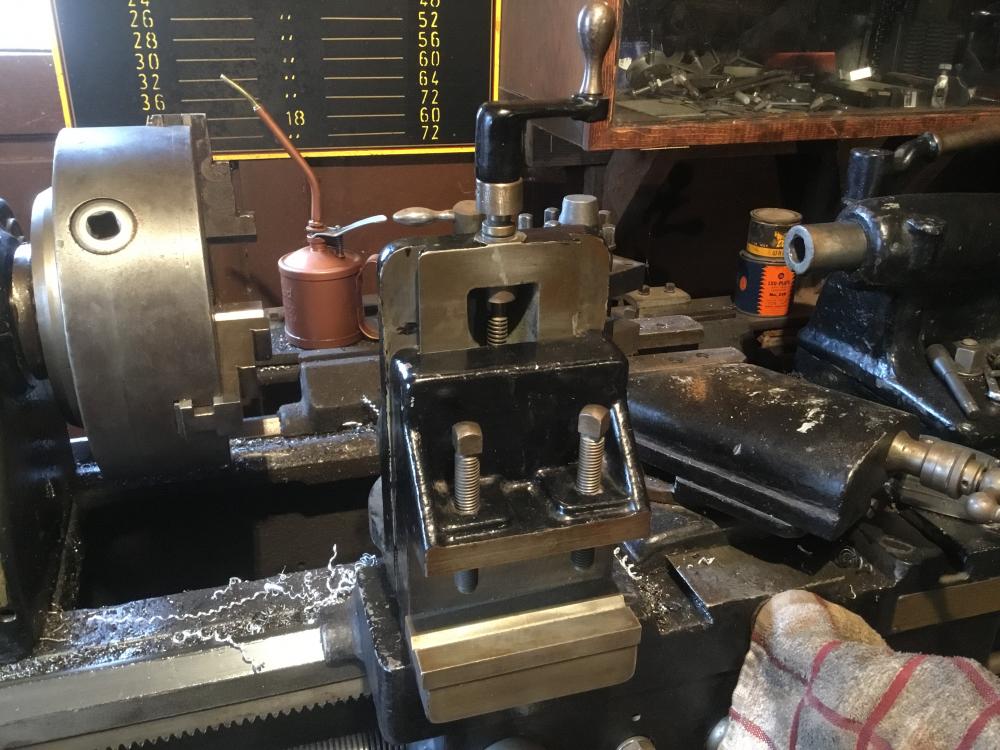

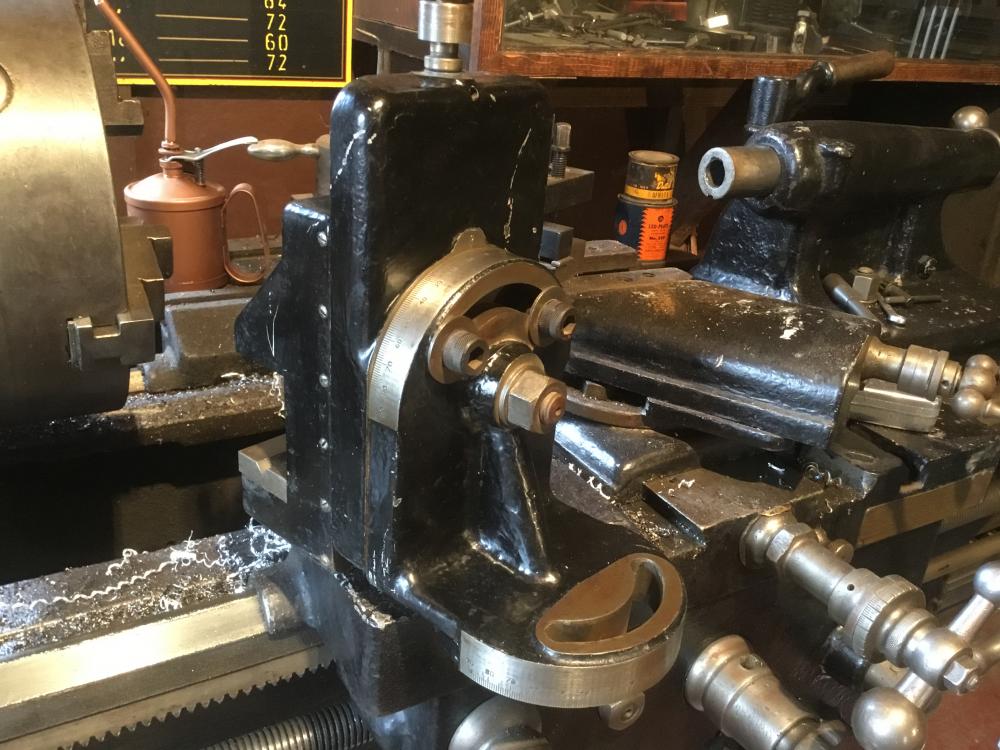

Yup, mounts to the compound with two 1/2” bolts. Chuck a mill cutter in the chuck and advance your compound forward and back the length you want the key way and towards the chuck till the desired depth. Works great but slow as heck.

Yup, mounts to the compound with two 1/2” bolts. Chuck a mill cutter in the chuck and advance your compound forward and back the length you want the key way and towards the chuck till the desired depth. Works great but slow as heck.

Jim

-

4 hours ago, Nodebt said:

Thomas, what are goats heads? In the middle of the night?

A nasty sticker.

-

-

12 hours ago, Greebe said:

Cool lathe, but not sure about the hanging chuck setup. My chucks have always been stored on a cart or a bench. I would either drop one of those on my foot or hit my head on one.

Got tired of stubbing my toes on them laying on the floor. I go barefooted most of the warmer part of the year.

Just now, Nodebt said:*drumming fingers*....

Juuusst kidding.... Still if you get time, it would be fun to look at!

Oh crap, forgot. Will get that pic in a few. Again. lol

Jim

-

9 hours ago, ThomasPowers said:

Looks good to me.

OK. Thanks for the heads up.

Jim

-

-

4 hours ago, Nodebt said:

What kind of machine did you desire? Word to the wise, you can't swear hereabouts. Thomas, I have a armature cutter that works on the same principal....

I was trying to find a decent American made vertical mill. No Chinese xxxx is allowed in my shop. But these mills bring 3000 bucks around here IF you can find one.

Jim

-

5 hours ago, Nodebt said:

Involute gear cutters can be expensive. Sometimes not so much if you can't buy a gear. And sometimes the price of a gear can pay for the cutter. I used to snap them up at auction cheap, others not knowing or caring what they are.

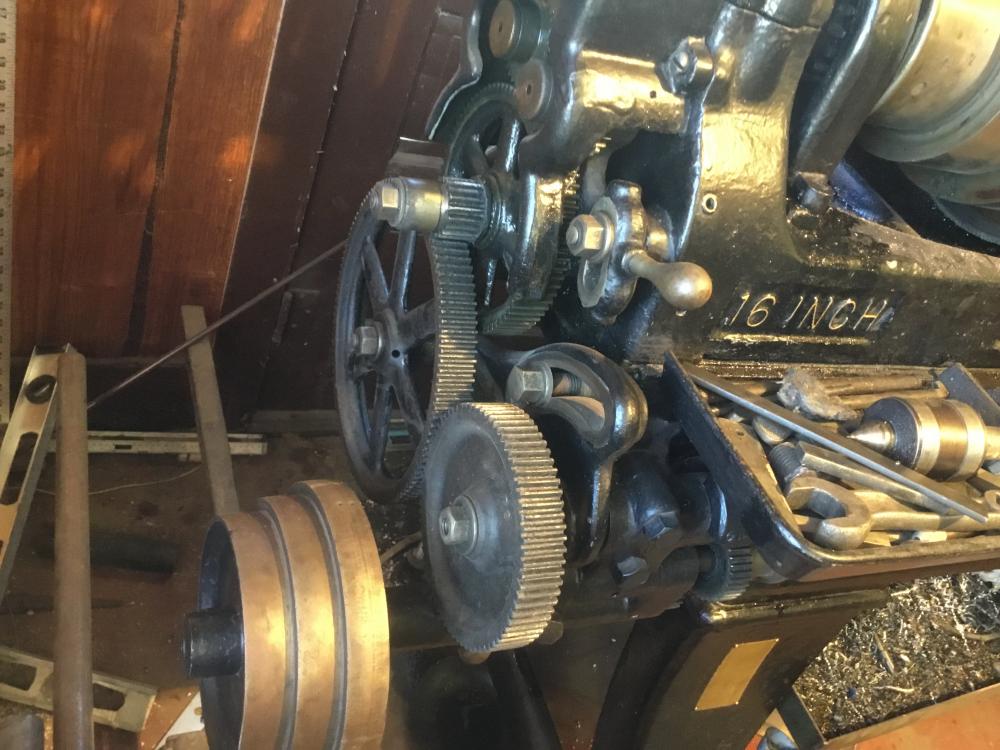

Absolutely. I got this mill with all the goodies for 500 bucks. I had run a vertical mill and was actually wanting one worse than this one but this was the only one for sale around here and the price couldn't be beat so I snatched it up and youtubed the xxxx out of it to learn how to operate it. Ruined the first 2 gear blanks learning the dividing head. Makes nice keyways. lol

Jim

-

5 hours ago, swedefiddle said:

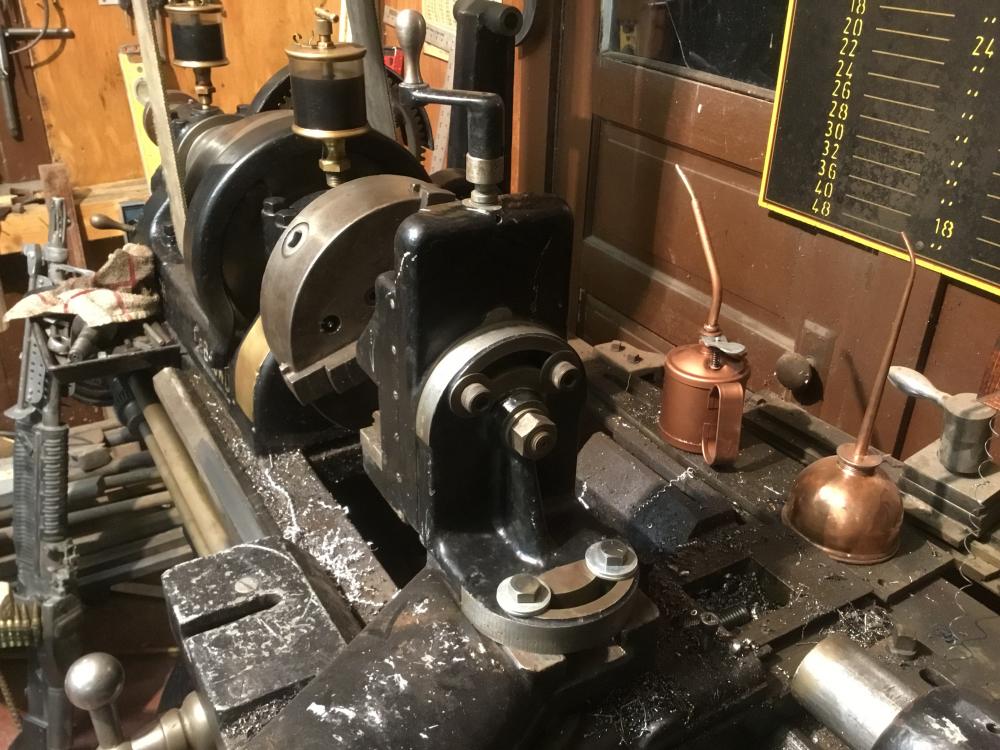

I used to have one. It is still alive in a friends basement workshop. You can mount a vise like thing on the carriage and turn it into a milling machine, etc......

Neil

Yup, a milling attachment. Got one for it too. used it to cut keyways. I'll post it in a bit. First need to learn how to down size my photos.

-

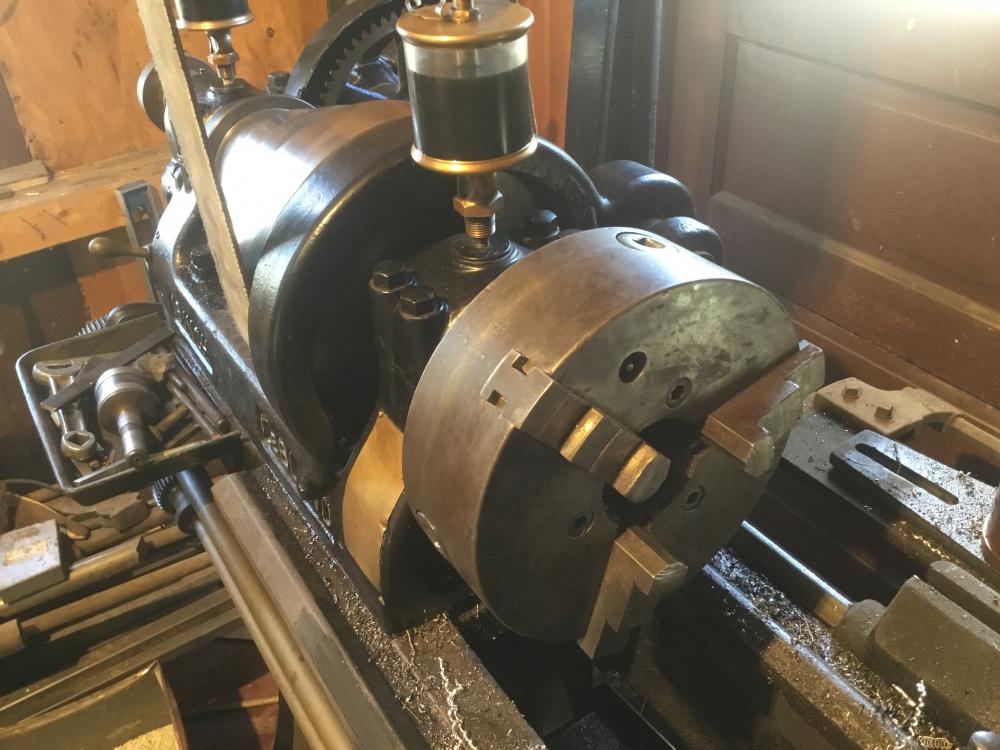

Forgot to say, it’s a LeBlond.

-

-

1 hour ago, TWISTEDWILLOW said:

that’s a nice silver! I’ve found two just like yours but they were both missing parts or had broken parts and neither looks as nice as yours. I’ve still got one rigged up in the shop that I use but it’s not near as complete as that one.

The automatic feed is nice when you want to run another machine at the same time. Traded a guy a small table saw/jointer for it. Found the saw in the local dumpster so the price was right.

-

Marine Corps, l/cpl ‘83 to ‘88. One year at Marine Barracks Concord CA/ Moffet Field for disciplinary action for punching an NCO at Infantry Training Camp Pendleton. The rest of my stint was 0351 anti tank/demolitions, weapons Company 2nd Battalion 9th Marines. Signed up the day the Marine Barracks was bombed in Beirut Lebanon.

-

Understood.

-

1 hour ago, Nodebt said:

You have a nice shop Jim. I used to really enjoy old machine tools, you have some unique ones. I bet you have a lot of fun in there!

Yup. Especially love old tools that I know the history of. The local blacksmith’s tools are my favorites.

-

Yup, I love vintage tools. Made to last. Don’t own a thing tool made in China! I have a drill bit that I used to make my 2nd Gatling gun. I made an 8 barreled .45 auto on a tripod. The bolts were 6” long grade 8 steel 1” bolts, turned down. I drilled half way through from both sides on my lathe. A total of 48”. Never resharpened the bit. Most people just laugh and tell me I’m full of it. It is a Danish Import brand? of drill bit that came in a 29 piece set that cost me 145 bucks. Mind you the drill bit never got hot enough that you couldn’t touch it but that’s obviously how you keep a drill bit sharp. That and copious amounts of 80/90 for lube.

-

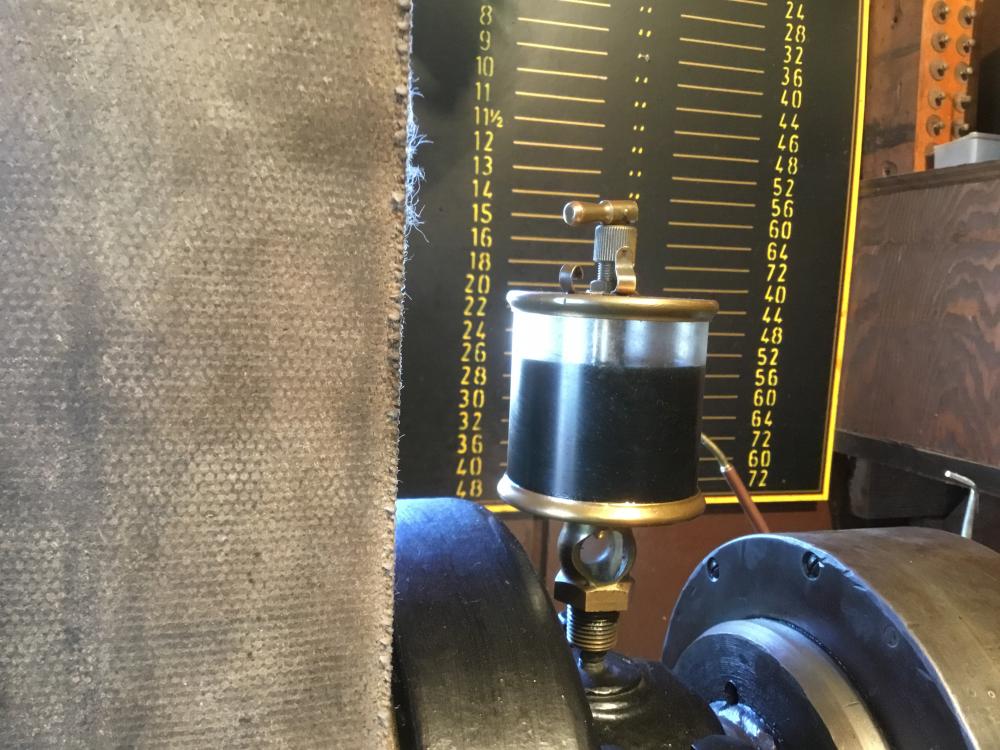

The head stock has a Babbitt bearing. I should know, I poured it lol. Took 3 attempts to get the heat right and not have either a porous bearing or lead squirting all over the place. There are no ball bearings in this machine at all.

-

-

-

Yup, corrected once again. They made 2 sizes of this planer with this one being the rarer small version. Missing the name plate on the reverse side.

-

Lol, yup has lead Babbitt bearings. What do you mean by what does the head stock use? Do you mean tail stock? 3 Morse taper.

-

-

-

A Schneider and Goosman shaper

in MIlls, Milling machines, etc

Posted

It is for sale.