-

Posts

42 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Horseman1

-

-

Frosty,

Thank you so much for all of that advice! I have noticed that many or most of the smiths in here defer to you on many things so I will be sure to take your word on all the safety issues you described. I am currently at the hardware store picking up parts for my new burner and when I think I'm done I'll send you a picture to see what more advice you may have for me.

Thanks again,

Phil

-

22 hours ago, swedefiddle said:

1/16"=.0625". That is way too large, Mig welding tips are about .025" to .035" and they screw 'into' something, quite often 1/4-20 thread.

The journey is beginning. Make notes in a scribbler so you can go back at any step. Never make 2 changes at one time, only ever 1 change.

You put your right foot in, You take your right foot out....................and you turn yourself around. That's what it's all about!!

Thanks Neil! I'm going to give rebuilding the T portion a try tomorrow. The maker drilled a hole through the T, put the pipe through and welded it, so I'll start that part from scratch. Shouldn't be too difficult.

21 hours ago, Irondragon ForgeClay Works said:Yep... 1/16 or 0.0625 orifice is way too large. That is the size we use in our burners for the propane fired Kiln which is 100 times or so bigger than a forge. When we built our 340 cubic inch propane forge the burner had a 0.0625 orifice which gave us the same result you are having. With some experimenting using different size orifices, I settled with a 0.0360 one that works very well. I would say with your current size forge you will have to go smaller than that or increase the size of the forge.

Huge difference, wow. Well I guess I'll be rebuilding the T portion seeing as the builder welded the pipe to the top of the T. All part of the fun.

Thanks for the info.

Phil

-

23 hours ago, ThomasPowers said:

Exactly; it looks like someone mixed up a blown burner with a naturally aspirated one---sort of like trying to build a car engine mixing up plans for diesel and gas engines.

If you can retrofit it to have the sizes and locations of a T burner then it is a T burner and is known to work and instructions for Tuning it are already on this site! Did you read the "READ THIS FIRST" thread that explains how to efficiently search for info on this massive and twisty website?

Please remember that we want folks to succeed in getting into blacksmithing; but we won't be bottle feeding them. (I'd worry if you were safe with smithing if you need too much help with the basics that have already been covered here many many times. I had a friend die from making a stupid mistake and he was an experienced smith and knew better!)

GIGO is a major factor on the net, the more and better information you can provide when asking a question the more likely the result will actually apply to your situation.

I'm really trying to learn the craft here. I thought asking for help here would be wise considering the number of people on here looking to help each other. I didn't realize that I couldn't ask questions before researching. I'm not looking to be spoon fed or bottle fed. I jumped in over my head like so many people do and now I'm asking questions and I'm doing my research.

Honestly, since I've only been on this forum for less than 24 hours and I asked my questions within the first 3min maybe cut a new guy a bit of slack. Or not, that's up to you, but assuming I'm here for the easy answer or quick fix or whatever you think I'm here for and responding to my questions like a xxxxxxx only makes you look bad.

I haven't much liked how you've approached me here and I've tried keeping my cool, so my apologies for if this offends you, I'm just trying to let you know how your approach was received.

-

Right on! That's the kind of attitude I was hoping to find here. Thanks again for reaching out. Going to figure out how to get to the hardware store before they close so I can maybe get this thing going before I go to bed tonight.

-

23 hours ago, ThomasPowers said:

Making the forge larger has NOTHING to do with the location of the orifice in the plumbing T. The Orifice size and location is what controls how much air gets entrained and mixed for the burn. Please read the Frosty T instructions as that seems like what the people who sold this to you were working from only messing it up with mods.

Are they still selling these poorly designed burners on Amazon?

I realize that the size of the forge has nothing to do with orifice placement in the T. I was thinking that the possibility of there being too much pressure in the forge because of how small it is might have something to do with why it's burning the way it is.

What I'm hearing you say is that if I use the pdf plans for the burner that Frosty put out in the forum I can make the necessary modifications and my burner will fire correctly and I shouldn't need to change my forge size any. Is that what you're saying?

I have no idea if these burners are still being sold on Amazon. I can see if it's still in my purchase history and look into it.

23 hours ago, Welshj said:"I'm absolutely here for the learning opportunity to become more proficient in forging and blacksmithing as a whole."

Then you've come to the right place. There's alot of very knowledgeable people on here.

You've gotta understand that there's many who just come asking the same questions repeatedly... versus researching a bit, or any. They just want the quick fix answer.

Not that you have- but you can then see why some responses seem... snippy.??

Thank you for the clarification about responses being "snippy" I realize that I am entirely new here and want to have the best experience I can, learn as much from those that know as I can and maybe someday contribute to helping someone else just starting out.

I am not a huge reader and learn more by doing, trial and error, and by watching and listening. This is as close as I can get to talking to a bunch of different professionals about my questions and possibly getting some of the best advice to set me on a solid path.

I totally jumped in over my head right off the bat and realized that as soon as my forge wouldn't heat steel. Hahaha. I'm now finding this forum to be extremely helpful.

I actually found Frosty's pdf and printed it out about an hour ago. I'm going to pull apart my current burner and make the necessary modifications and see how it goes from there.

Thanks Welshj for pointing me in a good direction.

-

I actually bought this burner off Amazon a while back. I didn't build it or tinker with anyone's design, it came as is. I'm here to ask questions and to learn from people who know the craft far better than myself not to step on anyone's d***. I'm absolutely here for the learning opportunity to become more proficient in forging and blacksmithing as a whole.

2 hours ago, Welshj said:Well, horseman- I'm going to leave the burner to the guys that are the experts on them... the one who designed the style you're using- you've already met. As in the FROSTY "T" burner.

That is a way nicer setup than what I'm working with.

So with the burner I have I'm hearing from people that my orifice is too big and too deep in the T. What would your recommendation be? Make my forge bigger with thicker ceramic wool and refractory cement, or scrap what I've got and build something else, or just buy one that's already dialed in?

-

6 hours ago, Frosty said:

Welcome aboard Horseman, glad to have you. If you put your general location in the header you'll have a chance of hooking up with members living within visiting distance.

Hi Frosty,

So I'm gathering that there is allot more to this than I originally thought. Hahaha!

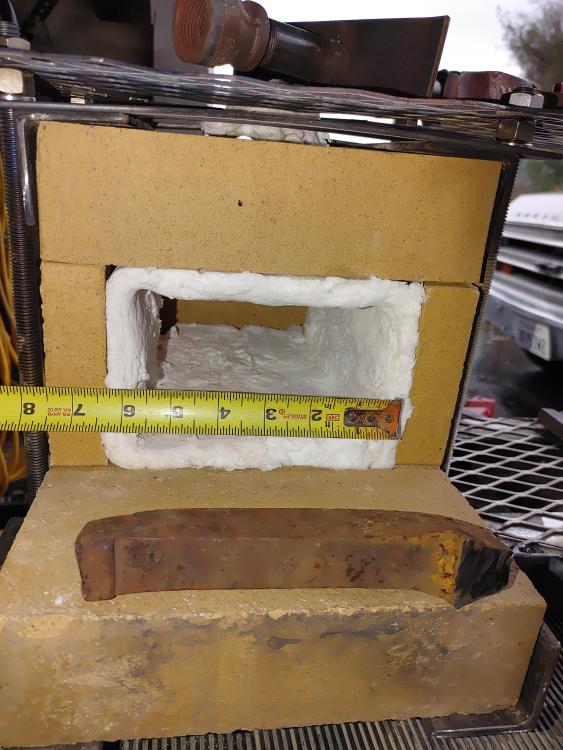

The cu in of my forge is approx. 173in³. The hole for the jet is 1/16". All the air ports and the burner flair are threaded. Do you think I should remove the threads to decrease drag/air turbulence?

Here are some pictures that might help.

-

6 hours ago, ThomasPowers said:

Now we are getting somewhere---what size is the orifice?

The opening is roughly 5.5"x3.5" and 9" deep.

From what I've been reading, my burner appears to be to big for my forge size. I'm only at 173in³ and this burner from what I've been reading should be good to hear at least 300in³

6 hours ago, Irondragon ForgeClay Works said:From the pictures of the dragons breath it looks to me the gas jet orifice is too large. What did you use for an orifice and how far into the T is it located? I'm pretty sure Frosty or Mikey will give better answers than I.

4 hours ago, Horseman1 said:The opening is roughly 5.5"x3.5" and 9" deep.

From what I've been reading, my burner appears to be to big for my forge size. I'm only at 173in³ and this burner from what I've been reading should be good to hear at least 300in³

The hole in the jet is 1/16" and all the openings are threaded. Should I remove the threads to reduce drag/ turbulence?

-

Hi Frosty,

I'm totally new to blacksmithing and I probably jumped off the deep end blindfolded so I'm struggling a little bit now trying to get my forge to heat the steel even above workable temperature. My burner does not seem to be burning efficiently, and I'm having a bunch of cold spots in the forge. I'm currently running propane at about 2-2.5psi. I've included a few pictures of my forge so you can see what I'm working with.

Some things I have already tried include raising and lowering the burner height, opening and closing the doors on one side or the other, or adjusting the doors on either side for airflow. I originally had full bricks on the sides, then switched to split bricks to increase the size of the interior of the forge.

Any suggestions you have for me would be greatly appreciated.

Thanks, Phil

-

6 hours ago, Irondragon ForgeClay Works said:

Only make one modification at a time,

I completely understand the value of the process of elimination and the scientific method of one variable change at a time. Thank you for the input. I have updated my profile a bit so maybe that will help.

-

It is not closed off on either side. When I close off one side the burner begins to chug and I get fireballs out the door. If I lower the burner down a half inch it sputters and gurgles like flames are backing up the burner. The steel doesn't get any hotter than a full orange color and that takes about 20min or so.

-

-

Thanks to both of you for your responses. To answer some of your questions Swedefiddle, I am using propane as fuel, my burner is in the exact center. And though I have thought about doing a forced air system using a blow-dryer I have yet to set that up.

I'm going to make some modifications tomorrow morning to see what happens, but will get some pictures for you tomorrow.

Thanks again,

Phil

-

I have built a gas forge and am having issues with cold spots in it. I've adjusted the fuel to air by regulating the fuel to between 1-5psi and lifted and dropped the height of my burner. I'm still not able to get the burner to jet in the center. The fuel seems to ignite toward the edge of the door. I'm thinking that I need more interior space in the forge to allow more space for the fuel to burn properly.

Please help me solve this puzzle as I'd really like to get on my way with trying this craft.

Sincerely,

Phil

New to the game

in Gas Forges

Posted

Here is the new burner that I built following Frosty's guidance. My mix tube is 4" x 1/2" at the 8:1 ratio and my mig tip is a 0.024 which was the smallest I found at the hardware store. Here are two pictures, one of the burner itself and the other of the flames it's producing from propane at 5psi. I'm sure I probably have a bit of tuning to do.

What do y'all think?