-

Posts

521 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Jobtiel1

-

-

A picture might be a good idea. A location as well.

~Jobtiel

-

-

Can you post a picture of the problem? I'm having difficulty visualizing what the problem is.

~Jobtiel

-

I haven't been able to forge yet, I'll have to find some time soon and make a nice letter opener. I've got an idea but maybe I should try getting it on paper first.

~Jobtiel

-

I feel you, when I was selling on Etsy I also got stressed sometimes when someone placed an order and the piece didn't come out as well as I wanted. I stopped due to time constraints but if I ever get back I definitely won't make to order anymore. Just make a couple of the things you want to sell and then sell it. Like a craft fair.

-

I got a WI wall anchor recently, like 30 by 50 mm bar. Very coarse stuff It cracks open at the slightest mishap. Would also make sense to use some more bendable stuff since the wooden, often oak, church frame in this case moves with the elements it would be nice that the anchors can give a bit.

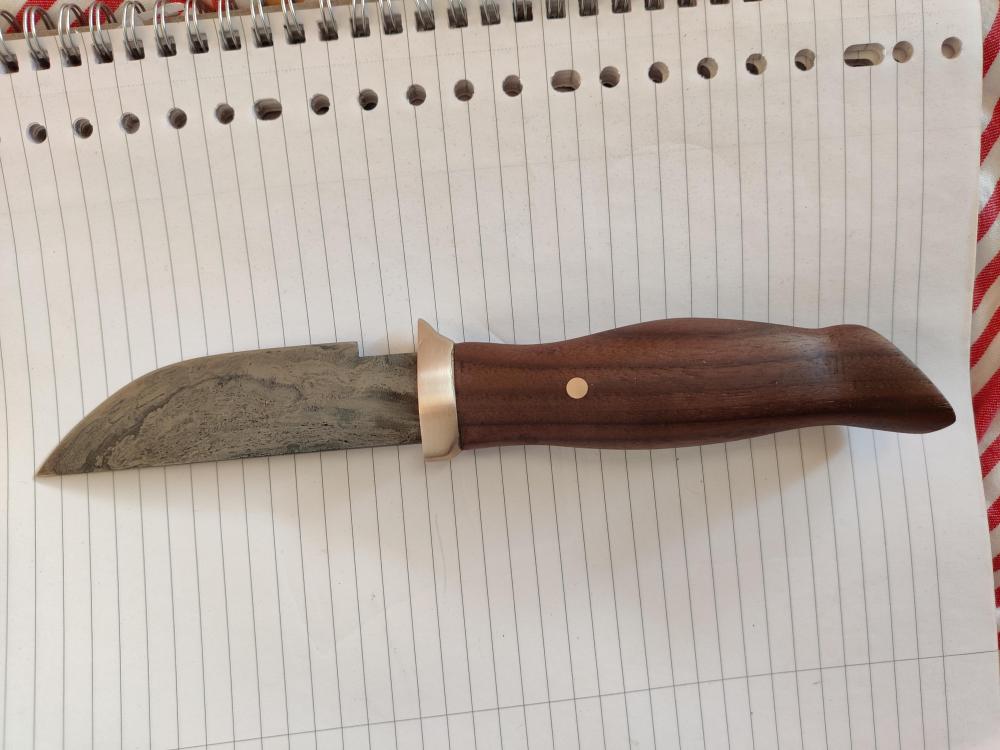

I made a san mai knife a few weeks ago using the stuff and the grain popped out pretty nicely.

~Jobtiel

-

Thanks Steve!

~Jobtiel

-

I get the "you do not have permission to view this topic" error when I try to open the BP.

~Jobtiel

-

Thomas, that wrought iron is a nice find, its a lot of iron indeed. Did they generally use highly refined wrought for wagon wheels or the poorly refined stuff?

~Jobtiel

-

Yes, it's an old saw blade ground to shape on the bench grinder

-

Little update on the oak chest, I've been working on the lock. Now it's just the latch that locks in the bolt left. That might involve some forge work as I haven' decided on the stock thickness for that. Also I have to wire brush the plate and apply some finish.

Here you can see the spring the keeps the bolt in place at the open and closed position.

Here a better picture of the bottom of the bolt where the key moves it left and right to open and close the lock.

The thing was all cold work. A lot of filing and chiselling. Now to make the latch and install it in the chest.

~Jobtiel

-

That sounds like a pretty good anvil! total weight of that bar would be around 83 Kilos, that's quite the farewell gift.

~Jobtiel

-

I've seen this type for sale some times over here, maybe even this exact one as I've seen one for sale recently that looked a lot like this one. I think you are supposed to put in dirt or sand to create your firepot kind of like a JABOD.

~Jobtiel

-

Can you post a picture? AFAIK only cast iron forge beds need to be lined. I have a steel forge bed and haven't lined it and it has been working without problems for over 2 years now.

~Jobtiel

-

That's also a good use. If your using the swage for multiples it would allow for easier consistency that way. and indeed seeing that there are spoon swages and a dishing form it would make sense that that curve is for a handle for those things.

~Jobtiel

-

I always thought that "french curve" was used for shovels or something of the like. If we're referring to the same part. Nice swage btw, it looks like it has all the useful components of a swage block.

Does it bounce around much due to the smaller size?

~Jobtiel

-

This seems like a nice challenge, and Brian has made some amazing stuff already. I've never made a letter opener, so I'll have to get my creative side up and running to think of something nice!

~Jobtiel

-

Looking good, looks like it will work well!

What are you going to make with it?

~Jobtiel

-

Yeah I agree, it's not something you think about and interesting to see the process like this. It looks to be somewhat true to how it used to be done too with the different tools and stuff.

I'm still deciding how I will mount it, either with some forged hardware, or mounted onto something wooded and then nailed to the wall with forged nails. I do have to make sure it can't fall off. I will mount it in the shed on the wall across my anvil.

~Jobtiel

-

-

Nice vise, looking good! How's the screw doing? The part that shows is looking good.

~Jobtiel

-

We put corn on the cob with butter and salt in some tin foil and grill that on the barbeque, absolutely delicious. Never heard of microwaving it, have to try that sometime when it's not bbq weather.

~Jobtiel

-

-

I'll just try it, worst that can happen is wasting fuel, and then I would know what I need to practice before a second attempt. Thanks for the links anyway I'll study them for some pointers.

~Jobtiel

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

Beautiful work again Alexandr!

I finished of a small adze I have been working on, and I started working on hardware for a wooden vise for the woodworking bench. I'll update with how I made it once it's done.

The adze is from 25mm square with a piece of 1095 forge welded for the edge. Hopefully it can do some bowl cutting work when out and about.

~Jobtiel