-

Posts

535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Chimaera

-

-

On 11/20/2022 at 1:03 AM, Shainarue said:

I don't have a brass mallet yet nor do I have a wooden or rawhide mallet

Looks great! I've more than once grabbed a thin log from the woodpile and used it as a mallet

-

Looks great! I just know that if mine wasn’t symmetrical I would forget to mirror it

-

Congratulations to your nephew. I like the kukri esque blade

-

-

I think my trigonometric education was more recent than many of the other good folks on here. I also have an innate love of math that I have found not everyone shares

-

JHCC has it correct. You could also determine the volume via the angle, but that is far more work.

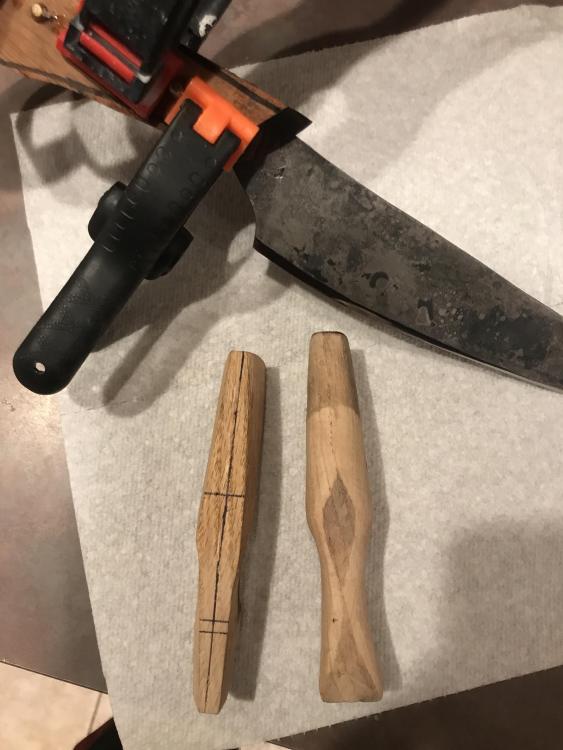

Got my first handle of 5 this week rough shaped and glued. Amazed by how much I’ve improved in getting my tang and wood flush.

Started prototyping a coke bottle hidden tang handle. Definitely still a lot of design work to go, but certainly better than the first one. Wishing I had a contact wheel to sand the radius, but apparently they don’t make those for 1x30s.

-

Just to back up JHCC with a couple of hard facts-

The volume of a cone can be modeled via the formula V=1/3B*H where B is the area of the base (cross sectional area of the original bar) and H is the height (length of the original bar). In this case, B can be modeled as either pi r^2 for round bar or L*W for bars with a rectangular cross section. Of course square bar is L^2. If we look at this again for a piece of square bar of side length L, we find that our cone (the taper) can be written as V=1/3L^2*H. With some simple algebra we can rewrite this into H=3V/L^2. Therefore, our final H (bar length) is equal to three times the original, if brought to a perfect cone and ignoring material loss due to scale formation etc.

His chisel argument relies on similar facts of geometry, but I’ll let you figure those ones out.

-

They look great! I think your rivet is fine.

-

Thanks les! Hopefully the handle is even better (though I’m not confident in that haha). Looking good MJL!

-

-

I think I understand now Les. Thanks for the help

-

Buzzkill, I really appreciate your guidance and expertise.

-

On 11/7/2022 at 9:21 AM, Melancholy Rivet said:

My brain interpreted it as a whimsically anthropomorphized knife, with a blade for a head and their hands on their hips!

haha, that's exactly what my brother said. Actually, verbatim it was, "Your tongs give very 'I'm not angry, just disappointed' vibes." It's definitely a confusing angle.

Billy, I like your knife. Padauk is one of my favorite woods, from its color to its workability to its smell. Only things better are burls. And maybe walnut.

Shaina, that's a beautiful brooch. I agree that it looks a bit big and heavy, but definitely a great proof of concept. Good luck on the smaller ones!

20 hours ago, Les L said:Chimaera, I would grind a bevel 1/2way through one side, weld that side turn it over and grind the crack to clean metal weld, normalize then re heat treat and temper.

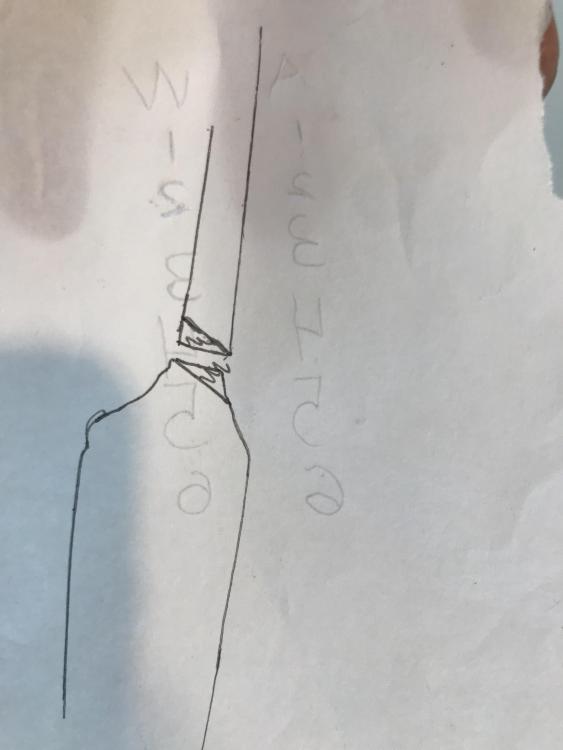

Les- I dont think I quite understand what you're saying. Do you mean something like this? Grinding both pieces to an angle so its not a straight vertical weld?

-

40 minutes ago, Irondragon ForgeClay Works said:

I have welded several tangs back on like yours and they have held just fine.

Great, I’m glad there’s hope. I already have a friend doing a welding project for me so I’ll see if he can do that too

-

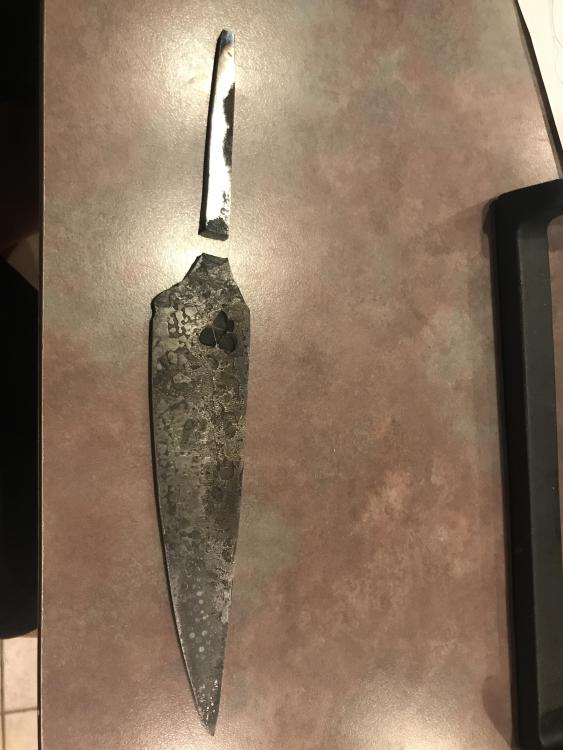

Had a couple days recently. Some triumphs and some failures. As for triumphs: made a new coal rake, a pair of offset v bits, a little herb chopper and a work in progress full tang kiritsuke. As for failures- my first three attempts at a hidden tang knife. They failed (in order) by: melting in the coal forge, almost immediately cracking (think the steel was bad) and snapping while trying to fit up the guard. Im about ready to lose my mind. Would it be possible to weld this final one back together? Even if not for use but just for decoration? Since it’s not in the blade I think it would work, but I’m not a welder

8 hours ago, BillyBones said:Out of 12 panes of glass 2 are left in the window. And of course they fell onto

Sorry to hear that billy. In Cincinnati it was pretty bad too. Had a fun time this morning trying to put the grill back on the deck.

-

On 10/7/2022 at 7:48 PM, TWISTEDWILLOW said:

ive still got a few piles of tools

That’s a good problem to have, willow.

Recently my brother got me a leather working kit for my birthday. Here are my first two sheaths- a squirrel tail neck knife and a nice EDC fixed blade. Still kicking myself for screwing up the stitching on the EDC. Overall though, I’m quite proud of myself.

-

Les, that's a lovely hawk. I've dreamed of making one for almost a year yet, but so far I haven't had any success. I need to improve my forgewelding. Chad, those look scrumptious!

-

Thanks simian. My understanding is that no, it doesn’t typically give as good of a contrast as regular pattern welded. However, I know some people are able to get pretty good contrast. I wonder if I had the wrong cable or screwed something up while welding it?

I’ve also tried instant coffee with no success, but I’ll try it again. I agree that this one did end up pretty cool even if it’s not what I wanted

-

Hey guys.

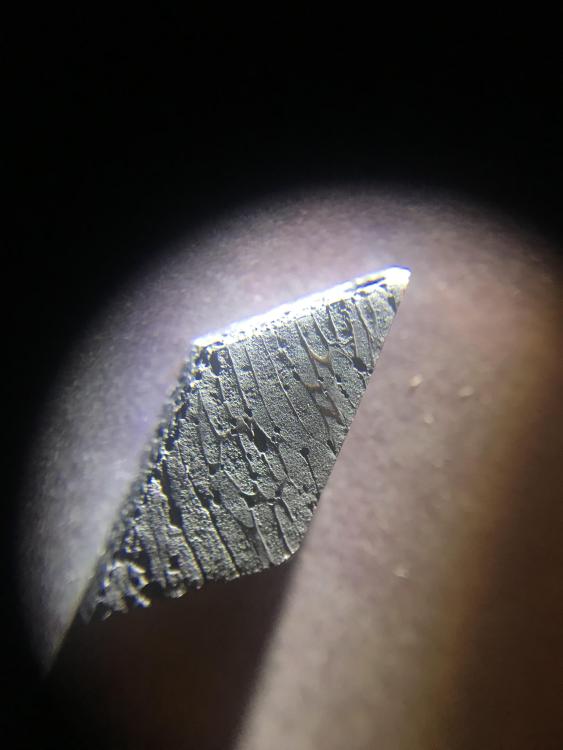

Recently I was able to, on my third or fourth attempt, finally make a successful billet of cable Damascus. Although it looks and feels pretty sound, I decided to keep this piece to decorative work only- no blades. I cut out an earring and got to etching- with very unsatisfactory results. No matter what I try, I can not get a good etch. I’ve tried several combinations and still nothing. I’ve tried it soft, hardened and tempered, hardened without temper- nothing. I’ve tried putting it in 40% ferric, 10% ferric, and boiling vinegar- nothing. The whole thing will turn black, but even with a very long etch I can not get much depth contrast. There is some depth, but even a light sanding with 5000 grit will remove it.

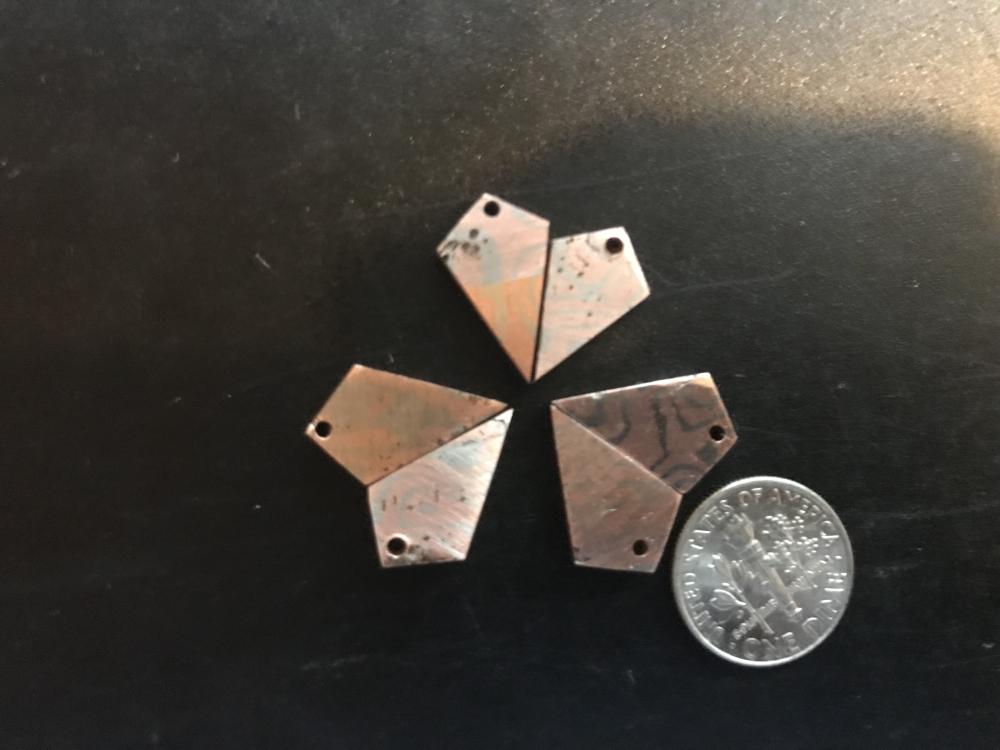

Attached is a photo of the earring. This time it was hardened without temper, etched for 24hrs in 10% ferric, wire brushed, then etched for a few min in boiling white vinegar. Finally I hit the high spots with 5000 grit wet paper. You can see that there is very moderate height and color contrast, but nothing close to the black and silver deep etch I see some people achieve.

At this point I’m desperate. I’m losing my mind over how to etch this stuff. I’ve etched mokume and wrought iron and those both went perfectly. This just isn’t working. I appreciate everyone’s help.

-

That's very interesting DH! I might have to try that next time I forget to oil my stuff, haha.

-

Everyone's stuff looks as amazing as always! I took a summer break from smithing, but I'm finally back in the "shop" and it feels great!! Forged out a little EDC fixed blade for my uncle. 5160 with Jatoba handle. I made a few leaves with varying levels of success (they all resemble leaves at least!) I have a very much work in progress kiritsuke looking thing. Not sure whether I'll continue with it or start over (it has a lot of problems). Just today I made three sets of somewhat matching mokume earrings. I think I might try sandblasting a pair for a nice matte finish, polishing another, and I'm unsure of what I'll do with the third. I also have a cable damascus earring currently etching. I ended up drilling through the side on the other one in the pair

. Struggling to get a good etch on my cable.

. Struggling to get a good etch on my cable.

Finally, I just recently got a new two burner propane forge. I've only lit it a couple times, so I'm excited to put it through the paces. I think it will be especially great for forgewelding.

-

Yesterday I visited my cousin, who is a master cabinetmaker. His work is simply breathtaking. While I was there, he gave me almost 20lbs of beautiful hardwood, cut to 3/8” (my go to knife scale thickness). The small yellow pieces may be Jatoba, but he’s not sure. The medium red brown pieces are all cherry, and the long ones are sapele (a kind of mahogany). He also gave me some walnut and a few knife blades. As they’re some unknown tool steel, I’m not sure if I’ll be able to use them, but I’d like to.

-

Pat- that sounds like a good deal. What weight hammer do you think works best? I’m wanting to make a hatchet/ tomahawk and am having limited success in the wrapped eye department.

Thomas- that rasptlesnake is awesome! The scales really make it pop!While I’ve only had a couple hours at the forge, I was able to knock out this little kiridashi. Probably my cleanest knife yet, mainly because it was mostly grinding. Scale finish on flats, satin finish on handle accents and file work, polish on bevel and edge.

I also made a blacksmiths knife that I’m too ashamed to post here.

Yesterday I visited my cousin, who is a master cabinetmaker. While I was there, he gave me almost 20lbs of beautiful hardwood, cut to the 3/8” (my go to knife scale thickness). The small yellow pieces may be Jatoba, but he’s not sure. The medium red brown pieces are all cherry, and the long ones are sapele (a kind of mahogany). He also gave me some walnut and a few knife blades. As they’re some unknown tool steel, I’m not sure if I’ll be able to use them, but I’d like to.

-

Yes, but I was trying to make it still look like a wrench, ie not drift it out

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

Got my first hidden tang finished. The blade is snapped and welded, the guard is scrapped, and the handle is rough- but it’s a knife. Oh, I also had to use my tan epoxy which looks like trash. Got two old knives reforged into more pretty and practical shapes, and have two itty bitties started for next time- a squirrel tail and a hidden tang. Also got my new flatter back from a friend: just need to find a handle and dress the face.