-

Posts

17 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Chriscarte82

-

-

-

-

Great advice thank you

-

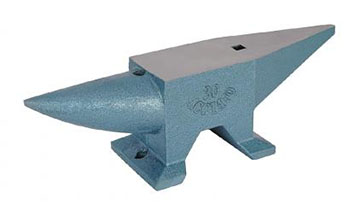

Good morning all, I wondered if anyone could shed any light on this anvil, from my online searches I think I've deduced that it's a mousehole anvil, however I'm stumped as to why there's no hardie or pritchel on the face. I am just negotiating a price with a guy and he's offered me this for £100. I currently have an anvil from Amazon, one of the Chinese 66lb Orions and wondered if it's worth upgrading.

-

Hi thanks for all the advice up to now, I posted a pic of the gauge to show which value my forge operates on as I know some use different readouts, not to confuse anyone but my issue was not that the bottle was empty the forge was off at the time the picture was taken, having spoken to the manufacturer they recommended a good running pressure of 0.1 -0.12 which along with frostys advice of listening and looking should see me through. I am in the process of ordering some suitable fire bricks to block up the back and some of the front to retain heat. Fingers crossed I should get a lot more use from my gas bottle

-

Yes I hardened it with the refractory coating rigidizer

-

Good afternoon all, I've had my devil forge 2 running for a few sessions and wondered if anyone could advise on correct running pressure. I think with experience I'll get the hang of managing the forge but I've gone though a 13 kg tank of propane in no time at all. I think I've probably been working the steel too cold so had to heat it multiple times meaning I've probably been burning it longer than necessary. Anyway any advice on running the forge would be greatly appreciated and hopefully save me a bit of cash

-

One step at a time for this rookie

-

-

Brilliant, very succinctly put, I'll take this on-board and reference YouTube for a few demos before getting to work. Thanks so much Thomas

-

Simply stunning

-

I will have to look that up, I'm assuming you mean drawing a file over the blade

-

-

So I've been eagerly sourcing supplies to start a home forge and have been itching to make a start. My forge has been sat waiting for a week for me to fire it up and get started. I thought I'd try make a blade from an old file from my hoard of flee market scrap. I'm sure to the weathered eye it's not that pretty but personally I couldn't be happier. Just need to cut down the tang l,drill the pin holes, heat treat, attach some scales (easier said than done for a total novice) polish and sharpen and I'm hopefully done.

-

Show me your anvil

in Anvils, Swage Blocks, and Mandrels

Posted · Edited by Mod30

Remove excessive quote.

Richard Postman is from what I have read is a legend regarding his knowledge of anvils I would love to hear his thoughts. Is he available through this forum or should I look him up. Thanks Thomas