Chad J.

-

Posts

569 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Chad J.

-

-

Just mark on the regulator where it runs best but if v you're having fun it's totally worth it. If the stems broke off you may be working the steel a little too cold, also look at the order you're doing things.

-

-

Wow, thanks! It means a lot coming from you.

-

I'm always reluctant to post after Alexandr. His stuff is simply amazing every time.

I'm almost out of round stock and my steel yard is currently closed on Saturdays, which I just found out today...

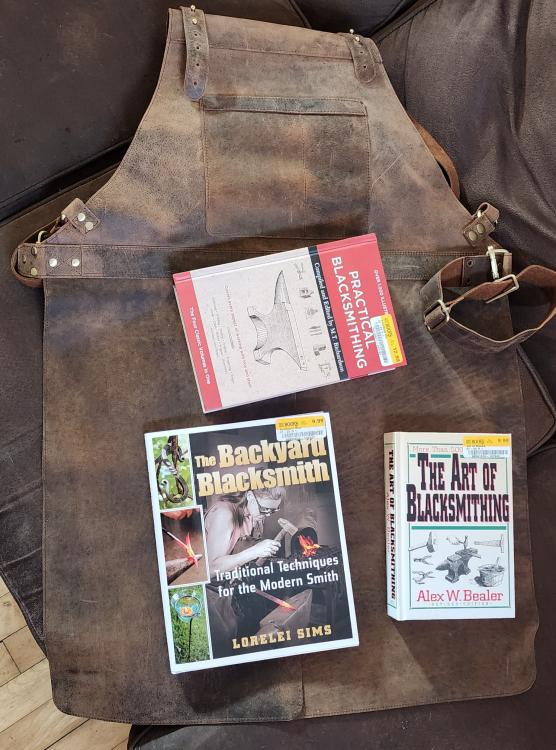

Anyway it's been a blade day. I have several that have been leaning against the wall along with a new arming sword I just started. I think I may start normalizing for a heat treat today. Well, at least the ones that can fit in my oven.

The kukri actually started as another xyphos that I messed up the handle.

-

The place that will fill my hundred pound propane tank had been a pain to get to, closed on Sundays and by 5 so I've been doing finish work as long as I can stand to be in the shop. I did my first stacked leather handle on Monday and did some shaking on it last night while also starting the finish sanding on the blade of this side dagger.

-

-

If ya need a tool, make a tool

-

Knocked out a quick spring fuller last night with 3/4 round welded on for the fullers. I ground them down a bit to be flatter as I well be using these for blades when I get that urge, which is actually really frequent. I also started a new Oakeshot 12 the other day. Learned my lesson on the first and started much closer to what I wanted my final measurements to be. So I got the blade rough forged in about 4 hours as opposed to 2 weeks. Started hammering the fuller and it's looking great.

-

Love the shape and handle. How tough is that coal to work and can it take a beating?

-

-

My ADHD turns every last flat surface into storage, and my focus is equivalent to a sawed off punt gun shot. I do generally put things in the same place but short of having specific plans or goals, my pile of in progress projects has spilled from the rack by my anvil to my tablesaw, grinder table, top of my forge, on my coal forge, the floor under the forge, and any other flat surface including in my kitchen and kitchen table. I have the room and will be putting in some dedicated work benches but propane is currently expensive...

-

-

That looks like a fun build Billy. How long did you make the tined?

-

-

-

I'll post the drawings and take pictures. I think I may need to do these on the coal forge due to size.

-

I've been drawing out how to do a set of bear claws for pulled pork. I was planning on starting with some 3/8 × 2 bar stock, cut and shape and put on some wooden handles. For the life of me I can't find forged versions on the internet. Maybe figure out how to get a bottle opener on it. Anyone made a set?

-

Hey Bug, welcome! I have an issue with bottle openers, every time I make one I have to test it. My liver gets mad at me for it.

That's a great first opener. How did you drift it open? My first bottle openers were curled and it took a hammer in for me to learn how to do punched and drifted openers.

-

Shainarue tongs are something you improve on a you do them. My first 2 sets are ugly, 3rd was better, and the 4th set is great for smaller stuff. But I also have multiple sets laying on the table because I didn't like how I forged them or I made them left handed.

-

Thanks George.

-

Not having a lot of hair myself I took it to work and I was told it was a bit heavy, I'll use a smaller starting stock and try again.

-

-

I have one again let my hammer overtake my senses in pushing myself on challenging blades. This time I have a rapier blade blank that is 42 inches on the blade itself and currently 49 inches overall. 5160 1/4 × 1 inch at the base tapering to 1/8 inch at the tip.

I have 2 options, 1; I go to another shop that has a 5 burner forge and bring the quench tank I'm going to build for it or 2; I do a trench forge with an air pipe and charcoal and laying the blade itself on a piece of angle iron to help keep it straight and heat evenly until I quench.

I will have a straightening jig ready to go in my post vice and I'm probably going to have to torch temper to straw.

Any tips or suggestions? I'm looking for holes and potential problems so I plan for them.

-

Often times I'll go on etsy and research design ideas, also helps me when I'm setting prices. I need to make a full set still.

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

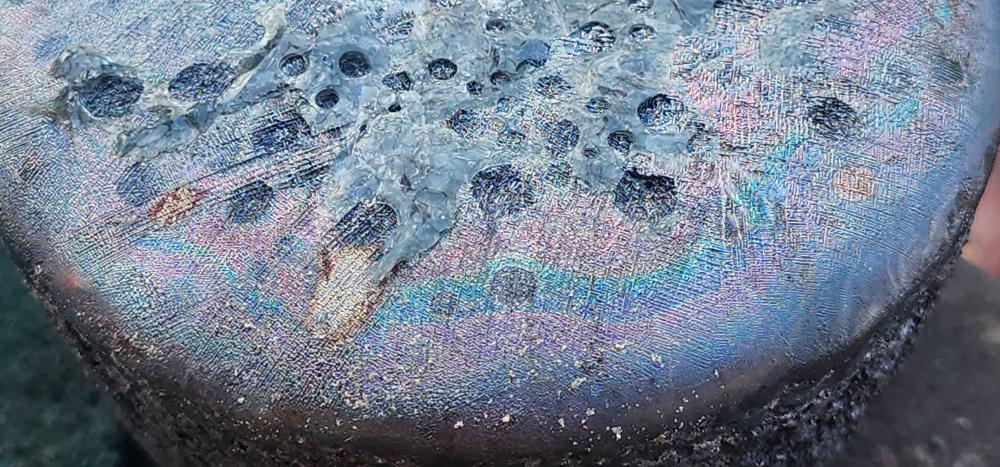

Chimaera unfortunately the one on the right to a warp on ht. I'm going to try tempering it in a jig tomorrow if that doesn't work I'm going to aneal it and start over.