SamJ1425

Members-

Posts

15 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Tacoma, WA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

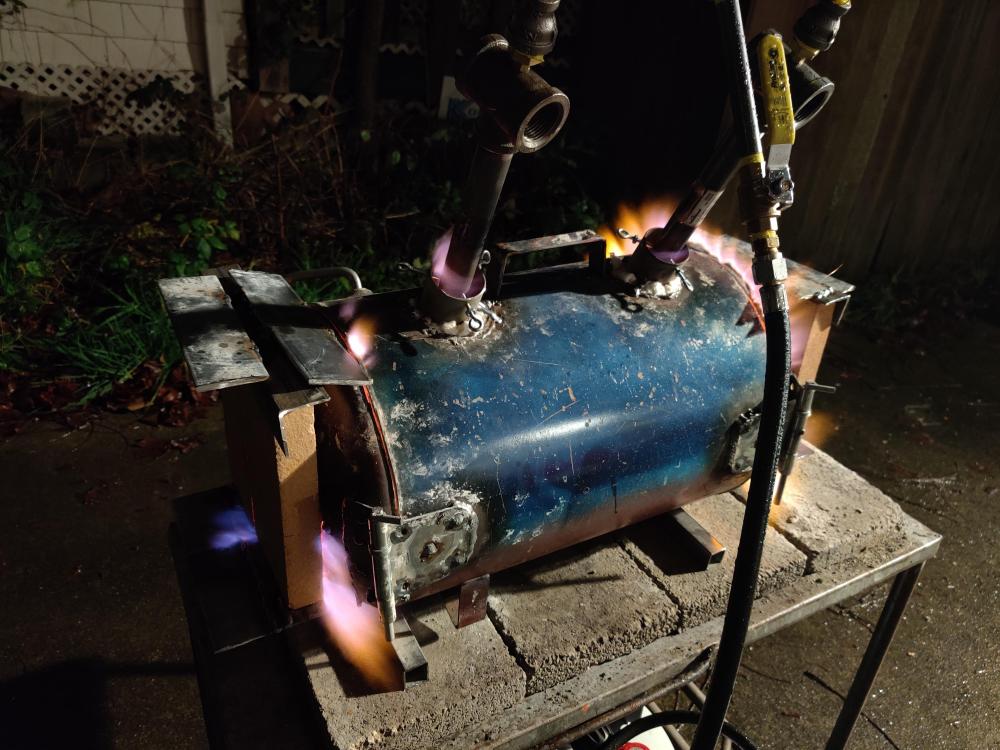

Alright I followed your guy's suggestions and mixed it so it was slightly more wet and it worked well and cured up great. I then got the doors cast and cut out and finished up the last welding steps. I ended up making some frosty t burners and hooked them in they seem to work great but I'm wondering if the flame is running right so feedback on that would be really appreciated. The final product in terms of all specs the inside forge chamber is 17in long and a diameter of 7in. The burners are each 3/4in with a 3/4in to 1in reducer, t joint is 1in with 3/4in chaser and the jet is a .35 mig tip the regulator is 0-30 psi. VID_20191220_212534.mp4 VID_20191220_212829.mp4 VID_20191220_212747.mp4 VID_20191220_212821.mp4 I'm wondering how I could better seal the gaps between the doors and main body so I don't have flames licking out or should I just weld the doors back on to seal it now that I have all of the inside made and cured?

-

I'm having trouble with my castable refractory. I have been buttering my ceramic fiber and I rigidized all of the layers. I buttered the final layer before mixing and applying the kastolite. When I mixed the kastolite with the water(2.7 ounces to each 1lb) it had a consistency of holding together but kind of crumpling after to much handling. It was a pain to get it to stick to it's self let alone the ceramic fiber and it kept falling apart. I'm at a loss as to what went wrong and I'm half a bag into the trash already. Someone please help me

-

Sorry this came from my phone, I'll make sure to edit my earlier post. Pics and drawings will come in a little while.

-

Has anyone tried this? I was thinking you could thread the outside of the nozzle and use it to fit both the inlet and outlet for the Venturi set up onto the newly threaded part. The multiple outlets would be like a small ribbon burner almost mixing the drawing are better with fuel was my thought

-

What about my understanding of the kastolite processes?

-

Also should I do kastolite for my forge doors or more ceramic fiber and kastolite instead

-

I've been to clay art center that's where I got my kastolite 30, burners and rigidizer but they don't have itc 100 or plistix they hadn't heard of plistix and itc 100 they said they stopped carrying because the company had changed their pricing and shipping or something and it became to difficult to deal with for how much they would have to sell it for and logistics So I'm at the stage where I have done all the layers I need of ceramic fiber and now I need to do the kastolite I've been reading everything I can find on the process but I wanted to make sure I do it right as I under stand it I mix the kastolite and after applying it in 1/2across everything I have to keep it enclosed in a 100 humidity while it sets and cures for at least 24 hours(I was planning on doing this by banging and tying it off in a garbage bag for this weekend) and then you have to fire it 2 separate times for maximum hardness first time at a low temp fire and then a high temp fire

-

Mikey I had tested the burner setup outside of the forge and it seemed like it was working well I know it's going to act a little bit differently when shooting into an enclosed space and isolated in its own environment and atmosphere but it seemed like it would work, is there any characteristics that the flame should have in an open atmosphere that will be indicative of how it will act in the forges' enclosed atmosphere and if so what should I be looking for? also the intake tube and flare are all one price that treads onto the burner output so I could change that out if I need to also the intake cap threads off too, is the a calculation of tube length and width and intake ratio that I can somehow determine? Where can I get the itc 100 or plistix in Tacoma Mikey?

-

Pnut I have been looking for plistix but haven't found anywhere to buy it I saw the links for ordering it here but was hesitant to do so because I couldn't even find documentation for it or mention of it anywhere besides these forums and leading about something is one thing but I learn better by watching or doing and wanted to have more confidence of a known quantity before I handled and used it

-

Also I'm planning on making a cut out on the doors with a little plate steel rest for bricks to rest on so I can block it off with them, do you think that is trying to over engineer the doors for the forge?

-

Ok I see what you mean, do you think I should modify my burner setup now or after I have the forge going to see how its working when it gets running?

-

I really like your forge design irondragon but I'm not seeing where the secondary air you mentioned is where did you introduce the secondary air?

-

Ok thanks Mikey, i realized i had another question i have 1/2 in thick ceramic wool, i bought it before i found the forums is it goijng to provid any problems to use it instead of 1 inch thick wool or is it fine to just do 4 layers for 2 inches

-

Any feedback on the forge would be great based on everything I have read I'm going to be using ceramic wool, coloidal silica rigidizer on the inside of the shell and the kastolite for the flame face and a high alumina kiln shelf for the floor ill put on a coating of itc 100 later but its going to take a little while to ship to me

-

I have been lurking here for a little while absorbing and reading everything I can before trying to ask some questions but i am getting to the point where i have most of what i need but i have a few questions I havent found answers to. First one is do I need to give 24 hours for the rigidizer to evaporate I heard that I needed to but then I keep seeing people mention just heat treating it with a propane torch so in that scenario it seems like they are applying it and torching it and then the next layer of ceramic wool without waiting for it to evaporate. Second is how far in do you put your burners into the forge I think I already have the angle right. Ill post some pictures of what i have currently