tardster

Members-

Posts

34 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by tardster

-

Eventless, good idea on sharing info on commercial forges... I recently purchased a Hell's Forge duel burner forge, I don't think my homemade forge will get hot enough to forge weld. I'm very happy with mine, it came already rigidized, firebricks for the floor, regulator and hose, and comes with castable refractory all for 300 bucks. I have about the same money in it as I do the homemade one I built. Make sure you follow the directions when setting it up though. I did the leak test and found a pinhole in a welded joint on the piping that goes to the burners. I called them up and they sent me out a new one and they even offered to refund me some of the purchase price. I just told them I'd be happy with the replacement part. Once I got the new part in I put it together and fired it up, it worked great. I forged a railroad spike knife using it, it took about 3 minutes at 4-5 psi to get the spike hot enough to start pounding on using just 1 burner. Honestly for the beginner I don't think you can go wrong with it especially for those who's building skills may not be that good (like me). I don't know yet if it will get hot enough to forge weld but as soon as I get the 15n20 and 1084 I plan on giving it a go and see what happens. I'll let you know how that goes even if it is a failure...

-

Nope, I heard it hit the wall and bounce off a few things I didn't even try lol...

-

Frosty, I did take the tip out but I did not clean it from the threaded end as you asked. I just poked my tip cleaner in from the other end so I will re-clean it from the threaded end. Oh and I made the same mistake and cleaned, or should I say tried to clean a mig tip that way and had the same results as you did lol...

-

I'm not quite sure what it is that's causing it to do that Mikey, you mentioned something about it being clogged up yesterday so I grabbed my torch tip cleaners and made sure it wasn't clogged up. I went through everything and made sure there wasn't any blockages anywhere else in the line. It's a full 20 bottle of propane so I don't think that could be it. Who knows, I'm sure I'm not doing something right. Maybe I will get a new regulator and see if that is the problem, it's the 1 that came with the burner so I'm sure it's a cheap one lol. On a good note though I was able to run the forge for 30 minutes playing around, I just made sure to adjust the choke when I would here it start to act up some. I managed to make me a horrible looking pair of tongs out of some rebar but at least I made something and got to use the forge for the first time so that makes me happy...

-

OK I went out and used the choke from the other direction. This time when I lit it up I got the whoosh and seen the flames come out the end of the forge, kinda startled me a little bit lol. Here is a video of it running at around 15 psi, I'm sure I have more tuning to do but it did seem to run better and got hotter faster. I did however get the same nice blue flame for a few minutes and then it would turn yellow and orange so I would have to adjust the choke to get it back to blue. I'm not sure if I'm just not using enough or to much psi or not because when I would move the choke I would get a real nice deep sound with the blue flame but then it would flutter some and almost go out until I moved the choke back to where it was.

-

Here you go Mikey, the first video is at 12 psi, the 2nd is at 18 psi and the last is at 20 psi. I don't know what happened because out of the forge it keeps blowing itself out no matter if I give it more gas or air or lower the gas or air. Sorry about the shortness of the vids but it kept blowing itself out as soon as I would start to adjust the choke...

-

I'll try to get it out and fire it up here in a little bit, I'm almost done with the honey do chore list for today lol. I thought it was weak myself but I thought it was because I only had it at 18 psi in the 2nd video, the first video it was around 10 or 11 psi. When I went to turn it up it would almost blew the flame out but I also had a firebrick in the back blocking off the opening. I figured it almost went out was because it wasn't allowing it to vent properly with the brick back there.

-

Well I lit up the forge today and had to adjust the burner depth to get a decent flame out of it. I can't go down any farther but with the right pressure it doesn't seem to bad. I did notice after a few minutes I would need to adjust the choke to get the blue flame back, is this normal to have to adjust several times while its running? I took a couple real short videos of it running, the first is right after I lit it. Once I put my phone down the flame started to get orange-ish and yellow so I adjusted the choke and got the blue flame back. The second video I put a piece of 1/4" thick 5160 steel in there and after a couple minutes it was glowing pretty good. I still have a few finishing touches to do to it but I'm happy with it so far...

-

i can do that mikey, should there be any room around the bottom of the burner thats inside the forge. the flare at the end of the burner is tight with the kaewool and castable.

-

LMAO... I'm 48 and was in the army for 10 years so I try to do things the right way or as close as I can get, work smarter not harder lol. I can see what your saying, maybe I'll order up a couple of those 1095 billets of amazon and give them a go or do you think that's getting ahead of myself?

-

Yea I don't have any plans for anything like that for a very long time, I want to get halfway decent at making knives before I jump into anything that big lol. As much as I love the looks of Damascus I plan on waiting on that too, let me see if I can make a knife or 12 out of railroad spikes before I get into using the good stuff. From what I was able to find somewhere in the 300-350 cubic inch range I believe. They say its 130000 btu if that helps, I did a web search and found a few people who said their forges were 20 lb propane bottles and they worked pretty good for them, of course I'm sure there are some that didn't have as good of luck with them but I haven't found any bad issues so far anywhere.

-

Thomas, I'm very sure it was because I didn't have enough pressure going through it at the time. The regulator came with the burner, it's a 30 lb adjustable regulator, here's a link to the burner I have and yes it is on top. Its set up in the 1-2 o'clock position. Link removed

-

Thomas, its only 12 inches deep from the front hole to the rear hole. I mainly just want to try to make some knives nothing very long at all. I figured if I made a knife 5 or 6 inches long by the time you put a tang on it you'd need close to 10-12 inches of room so I went with that. I'm not sure what the cubic inch area of it is, I haven't quite figured that one out yet. I don't know if it would work but I was going to use one of my wife's clothes rulers to measure the curved part and multiply that by the depth but I could be wrong on that one. It's been awhile since I had to do any of that type of figuring lol.

-

Thomas, I'm just using good ole propane that you buy for the grill, thanks for the info, that makes me feel quite a bit better now lol.

-

So is there anything that can be used to prevent a backfire?, I figured a flashback arrestor would do the trick.

-

Ok here's my first forge build, I know I need to put some castable around the opening but I wasn't sure if I was going to put the front on or not. I made it out of an old 11 gallon portable air tank that I didn't need any more, it looked beefier than the old 40lb propane bottle I have so I went with it. I don't know if there is any advantage of painting it or not but I was just going to leave it as it is and just use it.

-

SO there isn't any concern or way for a flashback happening in these burners?

-

Xxxx, that's right I meant flashback not flame, I told you this stuff messed me up lol. Ok which flashback arrestor is best for what we do or at least what I'm wanting to do? Yes Mikey, that's exactly what happened. I'm a welder and I honestly try to be as safe as I can and since the wife might get a bit upset if I burn the garage down or blow myself up I figured it would be better to get one lol.

-

Frosty, I just barely had the gas on so I'm pretty sure that is why the flame was coming out the choke holes. As I said I just lit it up and looked inside the forge at the flame and as I was getting ready to adjust the pressure on it I noticed the flame so I shut it down because I didn't want to take any chances. Here is a link to the flame arrestor I found on amazon, Link removed I feel it would be much safer not to mention I'd feel a lot more fuzzier inside knowing the flame cant go back through the pipe and get to the propane bottle lol.

-

Ok guys n gals, I'm almost done with my forge. I went in to fire it up and let it fully heat up for the first time tonight and before I could get the pressure turned up on the gas I noticed some of the flame coming out of the choke holes so I shut it off. It ran for about 10-20 seconds before I turned it off and once the gas was off the burner area at the top was pretty darn warm. I knew I needed to get a flame arrestor but this just shows me that its better for me to wait to fire it up until I get on. So after searching and searching I'm even more xxxxxxx up about which flame arrestor I should get and use. I've looked online and read about them but there are quite a few out there. I'm wanting to know which one should I get to use since you guys use them. Right now I'm just using a 20 lb grill sized bottle but soon I will be switching over to the bigger 100 lbs bottle. The ones I've seen on amazon and ebay all say they fit and work but when you the feedback there are a lot of them that say they had to get adapters and all of that.

-

Buzzkill, yes that was the flare I cut down. The flare was 3 inches long and with the castable and kaowool that only leaves me 2.5". I can cut a bigger hole in the forge to allow the flare to come through it which would allow me more distance from the castable and the tip of the flare or I could go with 1" of castable which would be easier and have the tip of the flare half an inch from the inside of the castable if that makes since.

-

ok took the tip off the burner, it was 3" long so I cut half and inch off so by the time the castable is on it should be even or inset so hopefully this will take care of that issue, I hope anyway lol... The burner is 1 of the geode stainless 130000 btu burners off amazon. I tried my hand at building my own but didn't like the way it worked so I figured I'd o with this until I get comfortable enough to do one of Frosty's or Mikey's (whomevers design it is) Tburner.

-

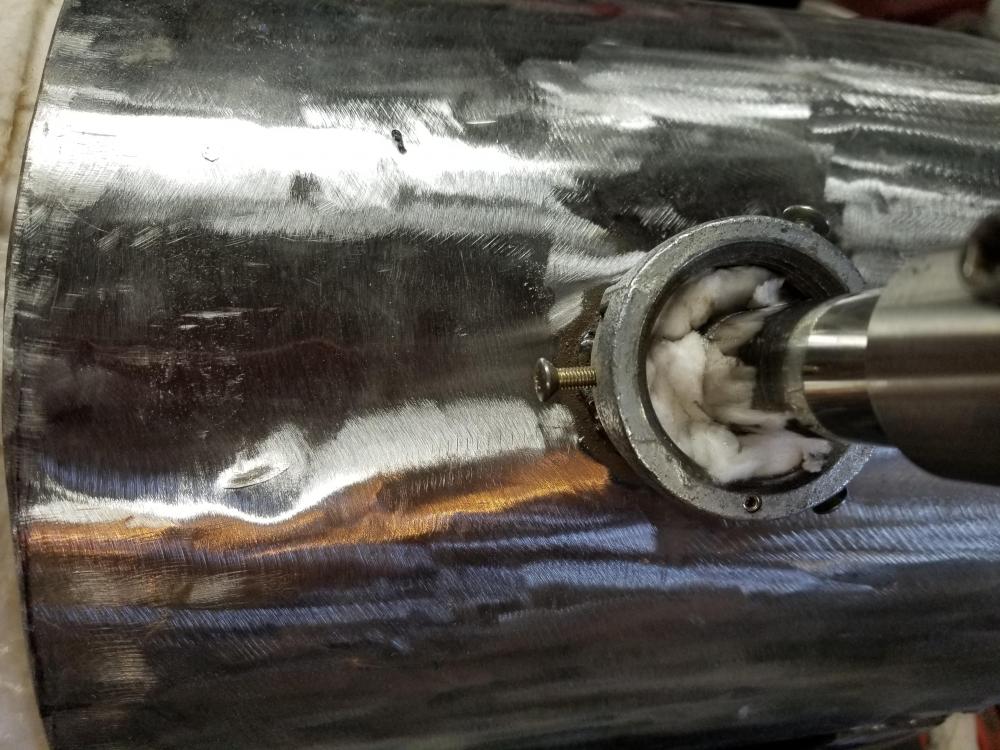

Thank you buzzkill. I put the kaowool in there (its 2" thick) and cut it out to fit most of the tip and lit up the forge just to see if everything was ok, plus I'm excited lol. As you said some of my tip does stick out past the kaowool and it got red hot so now I have to make sure to get all of the tip inside the kaowool and the castable once I finish it all up. My burner has 1 of those adjustable tips so my plan is to leave it where its at and make sure nothing sticks out. I let everything cool off and took a couple pics and noticed that after I shut it down the burner tube was pretty warm to the touch but while I had it going it was cold. I don't know if that's because the lame was being pushed out the end and once it was off the heat went up the tube at least that was my theory but I'm sure I'm wrong since I've been doing this for about 3 minutes now lol.

-

After 3 hours of searching the forums both through google and in IFI itself I still haven't found an answer to my question so I must ask unfortunately so here goes. When installing my burner into the forge how far should it go? Should it stick all the way through the kaowool and if so how far past the kaowool should it stick or sould it be partially through the kaowool like 1.5" of the 2" ? I watched one of those alec steele videos last night where he was building a forge. While building it he only went through the roof material (which was some sort of a brick material) about 3/4's of the way through it. I don't think that would work out to well with the kaowool material but I figured I'd ask just to make sure and finally should I use a little bit of the kaowool to close up the area around between the burner and its holder? Thanks in advance