unimog

Members-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by unimog

-

Show me your anvil stands

unimog replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

-

Pre3ssure, we enjoy the farm and the area here. We planted 500 trees on the farm 3 years ago and they growing well

-

No I don't have any attachments for the unimog

-

See attached pic above for the 404 unimog ex Belgian military troop transporter When 15 years old I started working for a blacksmith/ truck/ machinery mechanic in Denmark. I worked mostly on trucks and farm tractors but also helped out in the blacksmith shop. Remember many times where we young kids had to use sledges to work the hot iron before it got cold. The smith would use his small hammer to set the tempo and we had to keep up I have collected the tools over a 20 year period or so. Was too busy with in a professional job involving much travel to set up shop. Now retired and still having the interest is what motivates now. I have made tools, fire pokers and the like from time to time by moving the setup outside with a forklift

-

-

Thank you all for the comments. Very helpful Regarding the Ducks Nest is that a circular steel plate bolted on top of the clay lining to create a fire pot of sorts. Is that similar to using bricks to create a center for the fire to raise the fire up and save coals. Searching for it did not clarify much. Yes the machine shed is also the corn crib on the sides of the building originally filled from openings in the roof. The machine shed in the middle has a concrete floor. Originally it was used for horse wagons as a drive through being open in both ends. It dates back to the early 1800s. The first deed for the farmstead was dated 1802. The first building was the log cabin with a live spring running through the basement used for drinking water cooling milk etc. Good to have during Indian attacks also

-

Initially I was thinking about using the smoke house for the shop but it looks too small to spread out in

-

Here are a few pics of the old corncrib building that could be used for a blacksmith shop. Should be easy enough to close it in and add hood and smoke stack Have several sections of insulated stack pieces 6 inch inside diameter. Not sure if that will draft enough. 12 inch would be better I think. Or leave the building semi open and use as is? Or as Twisted has suggested add a wall fan

-

Jeep & Willy's & Lovers of old vehicles

unimog replied to Irondragon Forge ClayWorks's topic in Everything Else

I bought this unimog almost 20 years ago from military surplus stock in Europe and had it shipped over to Maryland. It is titled and runs well. It has a very flexible suspension with all coil springs That allows good traction in rough terrain and also you can difflock any axel or both together. It has a 6 cylinder Mercedes gas engine and has 6 speeds forward and two in reverse. The wheels are driven by portal axels that raise the axels up to give amazing ground clearance. -

Yes the larger anvil is a Hay Budden. Thank you for the suggestion to line the forge with clay. To use it inside the building it needs to have an exhaust. I have a duct fan I maybe able to set up to exhaust the smoke to the outside. Normal draft without a fan may not work? What is the experience here? The truck is a Mercedes Unimog model 404 50 years old this year It was a European military truck for most of its life

-

Collected the tools you see on the pics and now getting ready too set up a dedicated area on the farm. The old corn crib seems to be a good building for it with a 20 by 30 ft floor area. I need to mount the post vices on the welding table or perhaps on a dedicated stand I only have the rivet forge so will not be able to heat longer pieces. Next project should probably involve building a better forge and an exhaust system. What else would you recommend? What else woul

-

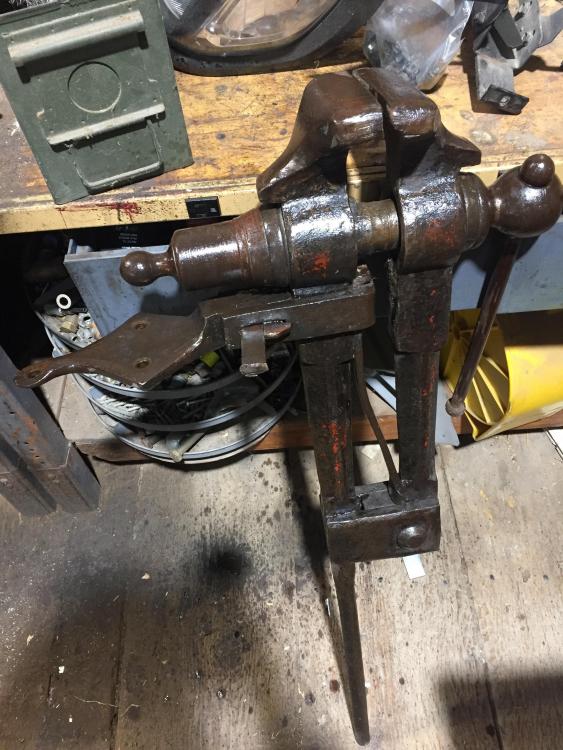

Had this old post vise for 20 years or so. Now retired decided to pull it out to to get it mounted. It works really well and has little to no wear in the screw. It is heavy and the jaws measure close to 6 inches across. Did not see any markings it. Also have a smaller one about 4 and a half inch jaws. Any thoughts on origin and age?

-

JHCC thank you for the tips for the forum. The Unimog is a unique off road truck with a very flexible suspension that allows all four wheels to touch the ground under most circumstances and coupled with the ability to lock up all four wheels for traction it can travel where others can't

-

yes Texas is a huge place. We lived in Houston at the time but I was doing some large scale construction projects in the West Texas area ( Permian Basin ). Also was working on a Power project in the Four Corners area of New Mexico so I am familiar with the wast distances

-

agreed your area is ideal for Unimogs and off roading We lived in Texas for 17 years

-

-

-

The customers were mostly local farmers that needed repairs made to their farm equipment and that was how the blacksmith shop was established in the late 1800"s. Later when cars trucks and tractors materialized a second shop was built to repair those as well and that was where I worked mostly except when they needed help in the blacksmith shop. The farmers were always there to complain about the weather and gossip and make deals on new or used equipment. We worked 6 days a week with Sundays off. Also we did repairs in the field for tractors and trucks as well as complete overhauls in the shop. I was able to overhaul a Diesel Mercedes truck engine by myself when I was 16 starting Friday afternoon when the truck was dropped off and having it roll out the shop Monday morning. Completed my apprenticeship when 18 but had a severe motorcycle accident. After getting out of hospital I was not in good shape so I decided since I could not work anyway to try to get an engineering degree instead. That turned out to require a lot of work initially since I had left school at 15 but 4 years later I graduated. Over the years here in Maryland I have collected some blacksmith equipment but never had the time to do anything with it. Between raising 9 adopted kids and a heavy travel schedule for my job it was hard to find time. But now I am retired I should be able to set it up. On the farm where we live there is a building 20 ft by 30 ft that I think will work for it.

-

Sorry I don't have any pictures of the shop. The shop was a separate building about 50 ft by 50 ft with the forge located in the middle of the shop. The anvil was huge perhaps in the 400 to 500 lb range. There were work benches with several post vises and an area with overhead pulleys and belts driving drilling machines and grinders etc. The upstairs had room for storage and there were racks outside for lengths of steel bars

-

Neil, thank you for your comments. Small world I grew up in Denmark and worked at the black smith shop in the mid 1900's. After my apprenticeship I studied to be a mechanical engineer and worked for a few years in Denmark as an engineer before immigrating to the US.

-

I am new to this forum. Used to work in a black smith shop many years ago as a teen apprentice. There was the master black smith and one other smith and 3 teen apprentices. I worked on ag equipment over the road trucks and also in the black smith when needed. The black smith work was mostly repairs to equipment, horse shoeing, steel tire replacements etc. There were no power hammers but the black smith would use us to get the most out each heat. He would line us up at the anvil with sledge hammers and set the tempo with his smaller hammer to work the hot iron. If we were slow to hit it there would a lot of "comments" from him. Started out when I was 15 and worked for room and board plus a very small salary.

-

Show me your anvil stands

unimog replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

OK location added Maryland -

Show me your anvil stands

unimog replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc