-

Posts

44 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Dan_the_DJ

-

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

Thanks, Ill try my best the next time I get the chance. Id work in the night no problem, since I cant sleep anyways, but the neighbors wouldnt find that quite polite of me -

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

Im having a tough time finding time to work in the forge. And the weather is not giving me a pass either -

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

There are some of course, but those are all mystery steels. I need plain HC of known compositions to minimize the variables of HT. I buy some old files and leaf springs on occasion, but Id like to be able to buy new stuff too -

What can one expect out of a camping/survival knife?

Dan_the_DJ replied to Dan_the_DJ's topic in Knife Making

Thanks guys. Im downloading the app and am actively searching the forums to find someone with a similar problem to mine. -

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

Pnut: This is just a test piece to see if the stock was large enough for what I had in mind. I will try to carburize this edge but in the future I will weld in a steel bit. As I said, I have access onoy to 4mm 1075. I dont know if thats too thin but I suspect it might be... -

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

Ill certainly try that sometime, thanks. But the problem is that I live in a very small town with only a few locations where steel is sold, but its only construction grade steel. Nothing hardenable. Well, not if you dont count some rebar which can be quenched and hardened to some degree, but its definitely subpar. The only places I can buy proper steel is a few places in the capital. There might be a lot more, but they have no presence online so I have no means of finding them. I have contacted blade makers from my country a number of times, some either outright refuse to tell me where they buy their steel and some that do either order from abroad or simply buy in bulk. None of this is an option for me really. Id have to start doing this as my livelihood to be able to justify spending the sort of money Id need to equip myself. There are some indications that the company I got my first commercial 1075 from will adjust its selling capacity towards small knifemakers and blacksmith shops in the area, so I will wait for that to get up and running as it is my best bet to date. I dont know the prices you guys pay for 1075 for example, but I paid somewhere around 3.5$ per kilo, which doesnt seem to bad for me -

What can one expect out of a camping/survival knife?

Dan_the_DJ replied to Dan_the_DJ's topic in Knife Making

I still have to learn forge welding, but it seems easier since I started using coal. I just have to be mindful of clinkers :) -

What can one expect out of a camping/survival knife?

Dan_the_DJ replied to Dan_the_DJ's topic in Knife Making

I use either an axe or a machete for nearly aything if I have them at hand, but if I dont, well... The knives are perfectly fine for almost anything save chopping and splitting large trunks. But theyre are still lacking in some ways. Maybe Ill get better over time, I should hope! I used to avoid files because theyre usually too thick and narrow for knives. Now that I started forging, its a different story altogether -

What can one expect out of a camping/survival knife?

Dan_the_DJ replied to Dan_the_DJ's topic in Knife Making

I ought to do just that... I reckon it would be easier with commercial 1075 I have. I cant be 100% sure with unknown files or springs that they would be the same every time. Europe has and my country in particular have more variety of different makers from all around the western and old eastern block xD You cant tell which is which so its less reliable to just assume each time that leaf spring are 5160. I mean maybe, but I doubt the soviets used the same exact alloy as the rest of Europe -

What can one expect out of a camping/survival knife?

Dan_the_DJ replied to Dan_the_DJ's topic in Knife Making

I didnt understand normalizing at first, for no good reason. Since I started normalizing, things have improved, but I still get some damage if I contact steel. Regarding the containers, its some type of steel for sure. Its magnetic and not stainless per say. Ive seen the same cans rust after a long while... Id ideally like my knife, labeled survival knife in the albums, to be able to do almost anything I might require of it, which it does. But there is that little problem of having an easy to "break" edge if Im not careful. I have whacked my knifes into rocks numerous times. When there is a flood, paricles of sand and larger rocks get wedged in trees close to the rivers and after it grows for a while, the tree owergrows it and then I come along and chop a branch hitting the rock and ruining my edge... I have also found pieces of metal in this way... Not to mention splitting pallet wood for example, on a camping trip or something like that. I always can find a nail it seems Edit: yes, I warm up the oil with a scrap piece of mild steel each time. The steel always gets hardmartensite formation is clearly visible in some of the pictures Thanks! Could it also be that Im over or undershooting with my tempering? I swear, my small survival knife seems to always chip while my other large survival knife tends to roll, other than a direct rock hit. Then it chips as well. Either way, Im really sensing some kind of weakness/brittleness in all my edged tools. And Im not really sure is it simple geometry or grains being somewhat enlarged. It they were outright massive, I guess my machete would be the first to break in half. But Im not lighty using any of my knives as well. I chopped more wood with those three than with an axe in all my life. True, my small survival knife lost its tip, but thats because it got used as a throwing knife a bit too vigorously. I can vaguely remember the grain on the break site. It wasnt perfect, but it was a long time ago. Back when I didnt really understand the meaning of that... Ill try my best to fine tune my HT as much as thats possible with my methods, might even try sending a couple of pieces for HT amd then finish it my way and do a comparison. -

Hello everyone, Didnt know how to frame this exactly, but Im interested to hear your experienced opinions on what a knife can and cant do. What is sort of expected of a knife? Let me explain: Obviously, the first thing would be that it doesnt bend or break easily or at all, but what about edge retention? Can you cut regular mild steel nails with a knife and expect it to still shave afterward? Im mainly asking because Im insecure about my heat treatment... I can get my knives shaving sharp and do bushcraft or skin animals, even shave without any problems. The edge dulls after a while, of course. But nothing really serious that a few passes on a clean leather belt wont fix. But trying to open a can of beans for example, the edge will get visibly dull immediately and will require sharpening. Touching any type of steel, be it food containers, nails, what have you, there is always visible damage and some rolling, sometimes little micro chips of the edge and considerable dulling. Im constantly seeing people using their freshly HTed blades to chop nails in half and shoving no edge damage at all! Is that even possible or do they leave their edges beefy on purpose as to pass the steel nail test? They usually shave to show all is well, but Im doubtfull to what degree is that "shaving" edge ground... Imma tell you, whacking a nail (or a rock, which happened more than once,when trimming weeds) with my knives, its not pretty... I have to mention that the edge is a relatively fine full flat with a slight convex without a micro bevel, usually shaving sharp. I get that there are tools that are made to cut other, softer steels, but those have a way different geometry and shape in general. Knifes are not dedicated tools for that obviously, but sometimes you really need to get that can opened or there is a nail stuck in a log youre splitting and Id like to not ruin my edge after an encounter like that every time. Im just afraid my knifes are not good enough... Im actually terrified to even give a knife to my friends because of this. I dont actuaoly mind any of this for my sake, Im used to it and I take care of my knives, but giving it a s a gift or some day selling a knife like that? It just doesnt seem like a kind thing to do... Im using old files and leaf springs mostly and I HT with a magnet, wait a couple dozen seconds past magnetic and quench in regular cooking oil. No problems with warps or cracks whatsoever, nor getting the steel hard. I temper to straw in the forge or in a kitchen oven. Maybe its large grain, but Id have to do a separate test on that to confirm. Im basically following any guide you can find for beginner knife makers and using the very same steels and methods. I bought a piece of 1075 to try and see if the problem lies with my HT or those mystery steels. If thats not the case, can the problem actually lie in my bevel and edge geometry? Ive never owned a knife made by a renowned blacksmith or some high end company to be able to see what a properly made knife can do. So to sum up, Im asking can a knife that is made for firemaking, general camping stuff and skinning/shaving if needs be, so a relatively sharp blade with a thinner edge be expected to get in contact with other steels like I mentioned above, albeit not hardened, and survive? By survive I mean that it will not suffer any noticeable edge damage so you can continue to do what you were doing... Sorry for the long post, Im just trying to understand what seems to be the problem with my knives. Am I simply expecting too much of a knife or is there really some sort of a problem? I dont expect much help without you all being able to inspect my work or actually watching me work in person, but the best I can do is show you what I have done in photos. Maybe some of it can help? Thank you all for your time and help. P.S. Ill be posting an imgur link to my albums so you can see some of the stuff I made so far. http://imgur.com/gallery/r7KHcRT http://imgur.com/gallery/hSunljh http://imgur.com/gallery/QJioC4h http://imgur.com/gallery/9fIWCMy http://imgur.com/gallery/NpBuxMf Here are the albums. Im always having trouble with imgur, hope they all work this time.

-

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

To date, Ive only found one place that sells 1075, but only as a sheet 4mm thick, which is a little bit limiting. To clarify, there are more places of course, but they either dont sell to individuals, companies only or they sell to individuals, but either in sizes/quantities that dont make sense for a beginner. There are some people who can afford to buy the whole sheet which is two square meters and then cut and resell it, but the prices are too high in that case. Regarding making high carbon steel... Im not, Im just following a recipe that has worked for me in the past and for some other people too. Im messing around because I still dont know forge welding -

Need some help with understanding forge welding

Dan_the_DJ replied to Dan_the_DJ's topic in Blacksmithing, General Discussion

I only have 1075, so nothing fancy there... I was only curious what would happen to it after welding temps Thanks yall. -

Need some help with understanding forge welding

Dan_the_DJ replied to Dan_the_DJ's topic in Blacksmithing, General Discussion

So basically, forge weld successfully > forge some more and grind to final shape > normalize and HT as you would any other axe ? -

Hello everyone, After reading for quite a while and learning that better preparedness is key, Im going to try forge welding for a second time very soon. Now armed with coal instead of charcoal, which makes managing heat higher and for longer easier, for me, I think Ill have better success than last time... I have just one question regarding the whole thing: Lets say I succeed to forge weld a 1075 bit to mild steel axe body, but what then? As far as I understand, the grain will be very large and otherwise unsuitable for an edge, so should I just do regular normalizing cycles and proceed with HT as usual or are there some more steps in between Im not aware of? Sorry if this is a stupid question to ask, but I couldnt find any information regarding my particular concern. Im just trying to better understand the process and maximize my chances of success. Thank you all for you help, cheers.

-

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

I had the same issue with carbon distribution. By logic, the surface should absorb more than the interior. But I wanted to know, could you solve this problem by heating that same piece of steel you just carburized in an inert atmosphere? In my mind, the inerior would want some more carbon, while the exterior has it in excess. Since there is no oxygen or anywhere for that carbon to escape to, shouldnt diffusion take care of things, giving you an end result with more or less equal carbon content in all places, except maybe for the core if your piece is too thick? Edit: I know of blister steel and how it was made, but Id really be interested to hear if you could make due using the way I just described. Its way faster, but certainly not better. -

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

I used charcoal until now. I think Ill use coal from now on. The one I have access to is a little bit unsuitable imo. To much smoke and slag. It wasnt meant to be used in a forge, but it works fine. For starters, it lasts way longer... The forge is a "V" type with a perforated pipe runing down the bottom to increase the length of heating area since I mostly work with longer, thinner pieces of steel. There are a few metal working shops, but none work with hardenable steels. At least not simple steels like plain high carbon. Im not sure about your doubts about the method of case hardening Im using. I used it with great success in the past. The best one being making a spring from mild steel. I cant atest to its longevity though. I guess we will have to see. The real test would be this axe Im working on now. Lastly, I totally agree that I picked the most labor intensive way of going on about it, but it was the only one that didnt include any forge welding. Ill try to remedy that in the future, but I first have to finish this one and see how it turns out thanks. -

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

Instead of lying the square with one side flush on the anvil and hammering the opposite one, I want to turn that square bar on one of its edges, and draw the blade out like that. Im uploading a sketch to hopefully make it a little bit clearer... Yes, thats what I meant. And I beg your pardon, but it does work. Super nice as well. I always hear its not viable... Well not really. People just take it as is I guess. Ive tried it and it works just fine for me. Heres a link of a guy doing it: I followed his recipe with slight alterations, but its basically the same deal. Dr. Fabrice Cognot used a similar method to make a viking age sword out of wrought iron, with limited success however. But his problem was that he added too much carbon (too much heat or too long of a bake time) which to my understanding made cast iron which then melted away his blade tip which only meant he had to make a shorter sword in the end. The point is, it does penetrate relatively deep. A few mm at least, which is more than enough for a sword, or my axe. Okay... This thing wont quote you anymore. Ill have to do it manually... "Learn how to forge weld. It's a necessary tool. Basically your approach will not work and forge welding is the key." Yeah, I always avoided it when using charcoal. I just couldnt achieve the necessary temperature consistently. With coal now, it seems more manageable. So Im trying that the next time Im free. "Steel is cheap and even easy to find for free." Not in my country it isnt xD I mean, you can find some, but shipping is abysmal to my house and there simply isnt a dimension that suits my needs. Its usually both, so yeah Well, too late now. Ill try it as is, see what becomes of it... Its a test piece anyway Ill definitely do that on the next go around. -

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

I kind of understood, but kind of didnt... Ive been thinking on my own a bit and Ive read all your replies. Im starting to get the picture, but I still like the idea of using the diagonal to spread out the material without ever forming a fishmouth. I use this kind of approach on arrowhead sockets. Usually gives me a bit more width to roll the thing around itself comoared to drawing a socket out with the little square flat on the face of the anvil. But like I already said, that would mean that Ill then have to punch the eye along the diagonal as well. And that is whats bothering me the most... -

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

I meant to ask would it have been better to draw out the blade by laying it on one edge, with that one diagonal being vertical on the anvil? That way, I can utilize Existing tapers to a point on both sides and thus, hopefully, eliminating fishmouth on either side. I guess that could work well enough for the blade, but I end up with the edges where the hole for the eye needs to be. Thats whats bothering me... And I know axes arent typicaly made from 1in squares, but this little axe can take it. I havent finished forging on it and it can already fit more or less. Its a 9-10 century battle axe anyway, it should not be very thick, so I have tons of material if the need arises to spread it a bit more. In fact, I might be left with decent bit of steel to grind off in the end... I dont have access to the kind of stock you guys usually use for axe making, but the design would allow it, so why not use what I have at hand, eh? I was kind of avoiding forge welding for a long time, but since I started using coal, I think it would be easier to achieve the prooer temperatures more reliably and evenly, so I might do a folded one in the near future. and lastly, you are correct. This is mild steel. I dont intend to weld in a high carbon bit, I intend to carburize the edge part for about an hour, which should add enough carbon to through harden such a thin profile, so no worries there I never really intended for this to work out so well as did... I dont have a pair of tongs at the moment, so leaving the thing attached to a meter long handle seemed like a good idea And besides, I wasnt really sure how much material I would need for my blade, so I went for that first. It turned out okay, so the next thing I did was to drill some holes and file them in to make a little slot where the drift will eventually go. Currently, Im working on a new pair of tongs and when I complete them, its onto the drift next. Only then can I make the eye... I know Im working a bit out of order, but I had free help that day, so I had to take advantage of that and forge out the blade fast This piece is kinda like a tomahawk anyway. Only its European and way older. -

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

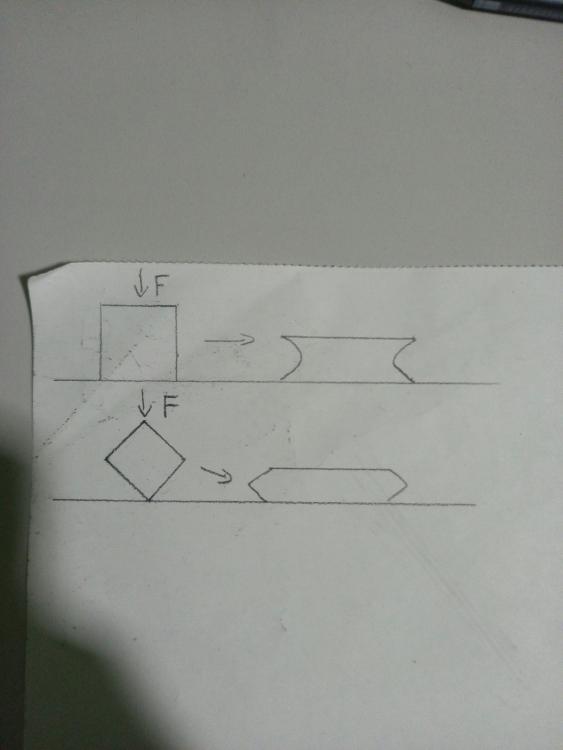

Yeah, I meant fish mouth, sorry. Edit: This part is meant for another atempt, Im posting some pictures of the current one. Could I possibly start spreading out material not by laying my square bar flat on the anvil, but on an edge, 45deg from one flat side? That way, at least in my head, there can be no fish mouth happening since there are edges on both sides and I might get a bit more material drawn out giving me a wider blade. The only problem I can see in this case is the eye part of the axe. Having the piece tilted 45deg will leave one edge directly where Id need to punch my hole and not enough material from the sides... This might not be such a problem Im perceiving it to be, Id like to hear your thoughts on the matter. Could I forge on that part a bit to make it more suitable for an axe eye and how to go about it? Edit: Here is the very rough forged piece next to the axe Im aiming to make: -

Trouble forging 1in square stock

Dan_the_DJ replied to Dan_the_DJ's topic in Axes, Hatchets, Hawks, Choppers, etc

Thanks guys. Ill try to fix things as best as possible. This was just a test piece anyway -

Hi everyone, As the title states, Im having difficulty forging one inch square bars. Whats happening is called fishtailing I believe. Im widening the bar for a small axe blade with a crosspien hammer with a striker buddy to speed thing up and Im getting cold shuts along the ends. Or I certainly will if I dont do something soon. There is only minor cold shutting along the future edge which would need a trim anyways, but there are some massive shuts in the making along the other two bar edges, the ones that are getting stretched apart from each other. How to fix and avoid this altogether? Is there a way to fix it now without grinding or any material loss? Im sorry if this is too obvious to most of you, but this is the first time Im doing such a large shape deformation and the first time Im encountering this problem. Thank you all for your help and understanding :)

-

Sorry Thomas, I didnt get a reply notification. I might be able to, but thats a longshot. They dont keep steel scrap here, its collected and sent elsewhere to be recycled. I can buy regular structural steel in many forms from a depo nearby. That will have to suffice.

-

Ill keep an eye out, but the chances of finding appropriate pieces are slim. Its a small place where Im from, not a lot of variety. Seems to me, the easiest thing would be to learn forge welding once and for all