Chris J Dixon

-

Posts

51 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Chris J Dixon

-

-

-

Wow! Nice score Pedro!

Stopped by an auction today and saw a guy carrying out his pallet full of goodies. Asked if he’d sell me the oil rag can. He looked at me like I was crazy and said to give him $10 and a hand. I gladly obliged. Stopped by my local body shop and picked up an empty laquer thinner can. Cut the top off and presto, a 10 gal. quench tank with a lid. Now to decide what to fill it with.

-

Rebar is to blacksmithing as pallet wood is to woodworking.

-

“Inherited” a couple of cross cut saws. One is 49” and the other is 55”.

What do you do with those?

....:..besides cut trees.

-

It’s saddens me that I have nothing to add to this conversation.

No spice, no flavor nothing but tasteless anecdotes.

-

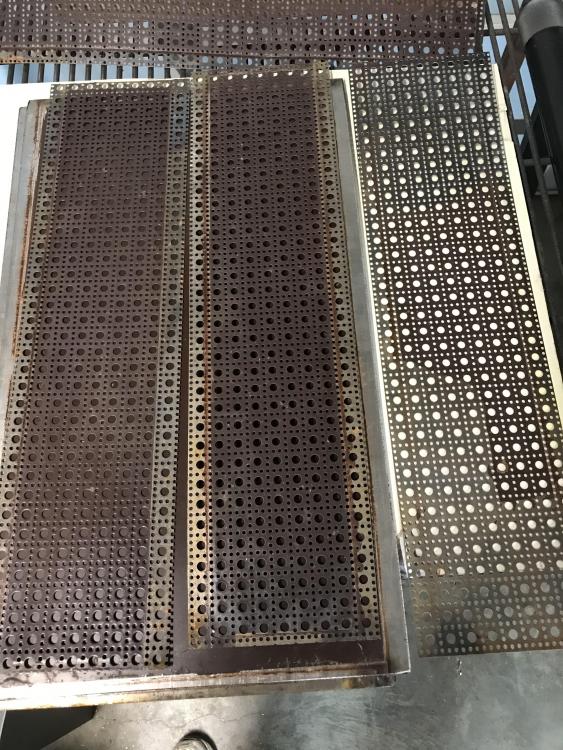

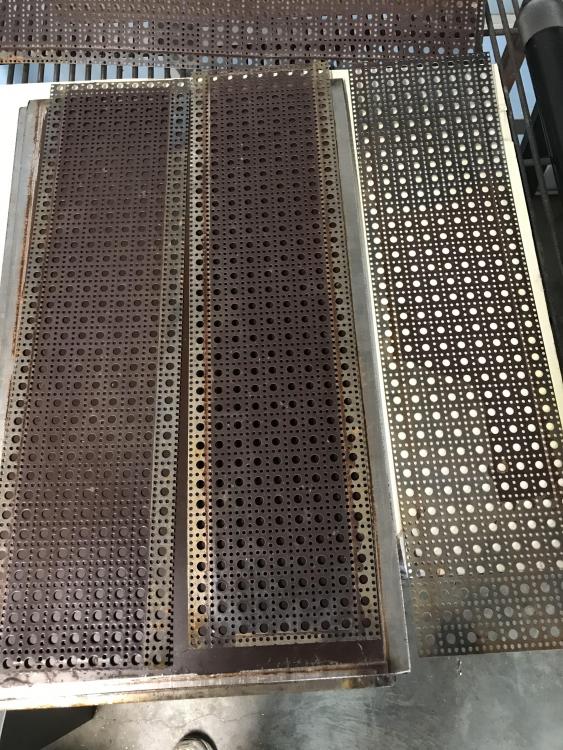

Salvaged some steel from a bed frame. Some nice sheet metal and a few pieces of perforated sheet as well as 2 - 44” pieces of angle. Started making JHCC’s bed rail bolt tongs. Will post progress and pics on that thread. Made a fire striker quenched in water from a piece of the angle too. It sparked nice on the grinder but I forgot to take a picture. Maybe will post results in a fire striker thread.

-

It sparks like medium carbon steel. I folded a couple of 18” sections to make JHCC’s bolt tongs and then made a small section into a fire striker and quenched it in water. Will test tomorrow.

-

45 minutes ago, Frosty said:

The bed frame angle iron is NOT mild steel, it's in the medium carbon range and is tough strong stock.

Frosty,

I found that out when I ground it. I saw someone made a pair of bolt Tongs by folding and flattening a piece of it. I might try that. Dont quench! I know that too.

Yes, perforated sheet. Sorry I’ll try to use proper termination as best as I can from here on out.

By “dump” I meant that someone dumped it. We have proper landfills in our area so anything dumped roadside is free for the taking and I usually take the other stuff to dispose of it properly. Make the world a better place and all that jazz, you know.

-

-

-

On 1/6/2019 at 11:20 PM, Glenn said:

Use the back of your hand to sense if something is hot. Much more sensitive than the front of the hand that does all the work.

Not only this but the instance of heat to the fingertips causes the brain to clinch and pull the hand away. If the piece sticks or you actually "succeed" in grabbing it, you're in for a bad burn not just on the fingertips. The back of the hand pulls away with no clinch.

These are all such great pieces of information. Thanks guys and gals!!

-

I guess it’s who you talk to. Helped a friend clear out a storage locker he bought at auction. This was in the mix and he gave it to me for my troubles. I made a quick little hanger for it and man did it make quick work of that coil spring! Now I can get busy making tools. Had a hard time taking it so I’ll have to use it to make him something nice.

-

I agree. An indispensable tool to have in my opinion. I have a long and short handled set in my tool box.

-

Helped a gentleman haul some hay bales that had toppled off of his truck and scored me a drill press today! It’s a 16 speed Jet on a homemade stand. It has a tiny wobble In the chuck so I’m going to take the arbor (not sure of correct terminology) out and clean the tapered shaft and see if that cures it. It should clean up nicely.

-

Man! I've gone through this thread and I must be talking to the wrong people or maybe talking the wrong way. Seems anything in Alberta is either at a premium price or they're keeping it to sell as scrap. I'm envious (to a point) of all your finds. Maybe I need to hone my skills.

-

Is there a gap where your burner goes through into your forge? I'm talking between your burner and your mount. If there is air coming in around the burner, it will do this as well. I just stuffed some kaowool between my burner and my mount to stop it. Just talking out loud at this point.

-

I know I'm new here but I'm going to comment and say that it is definitely an alignment issue. My burner is a Ron Riel inspired burner, but similar by design and if I rock my tip out of center, I get that same blue flame. I messed with it today and changed tips from .023 - .035 and position to tune it and found that the smaller tip made a smaller flame that took longer to heat up the forge. Once I put in the .030 tip and centered it, with my flare flush with the ceiling, I had a very hot and almost neutral flame. I have to run my regulator at almost 45psi to get a good, hot burn even though it will heat up at 15-20 psi, it takes forever. Truth be told, an .030 Lincoln mig tip is actually closer to .040 and yes I tested the whole pack. Just keep messing with it and listen to the guys above and most likely, below this post.

-

-

Here's my forge. It's made out of 2" angle and 4-1/2 X 9 firebricks with a burner that I copied off of the internet which I believe is a Riel inspired burner. Inside volume is around 245 cu in which I'm thinking is still a little big. I've yet to add a front shelf and I plan on putting refractory cement in the bottom to level it which will cut into my cu in some. This was the first fire and it quickly blew itself out which I realized was air coming in around the burner so I stuffed some of my ceramic blanket in there to stop that and moved the burner to only stick out about an 1/8". It seems to work good for now. I'm not sure how long the firebricks will last but I suppose time will tell. If I end up replacing the bricks, I'll probably make a new top as this one warped when I welded the burner mount on the top but it still hits the center.

I like simple, but now that I've seen these ribbon burners, I'm thinking of a new build. But first to the anvil!!

-

Obviously new to the forum but I've been moving sheet metal back to a predetermined shape for as many years as I can remember in the Collision and Restoration trade. Shaping steel cold has it's merits but the warmth of the forge is what's grabbed my attention lately. I'm very new to the craft but have accumulated tools and equipment enough to dive in head long. I look forward to learning from all of you.

I've built a simple propane forge and will post some pics for your scrutiny and advice in the next couple of days. I would love to use coal but am close to a set of neighbors who complain about smoke when we have a backyard fire so I'll keep the peace and use gas.

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

After I salvaged my treadmills, I tried my hand at a few things. My first bottle opener (was and eye opener), broke the bedrail tings working the too cold. Welded them and will try again tomorrow. Made a handle for my brushes and a couple candle holders. Das inspired me to try making one like his. For a newb, it turned out pretty good. A couple different textures on it. Ball peen on the base and wood grain on the handle. That really tested me but was super fun!