RichG

Members-

Posts

14 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Central Florida

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Believe it or not, we’ve actually watched it a couple of times. LOL. It’s what old married people do, watch old movies.

-

More so than my wife I’m sure. LOL,

-

So I know I said I was gonna do stock removal, but I started hammering and It sorta took on a life of its own. This started as half of a lawn mower blade. Tested a part of the blade first and after the test quench in canola oil it was hard, at least with a file test. Hammered out the basic shape then stared refining with my belt grinder. Still a lot to do, but happy so far for a test run. Thanks to all for the help and advice.

-

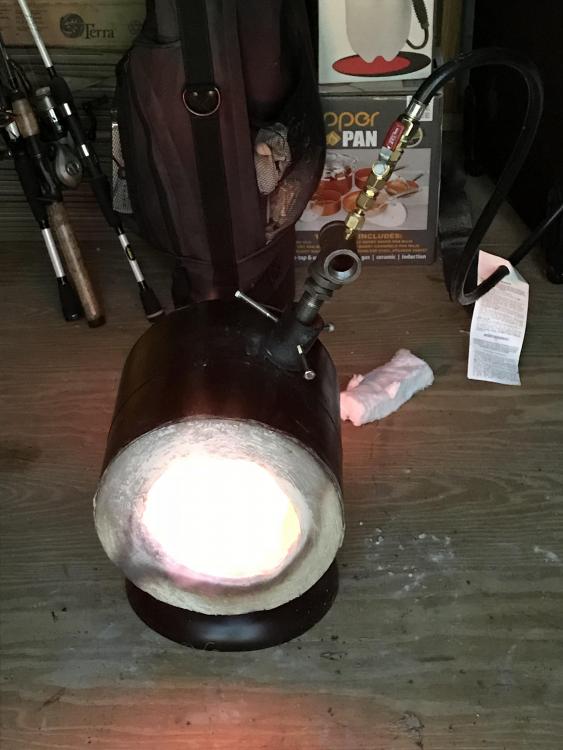

Thanks Mike and thanks much for suggesting the 1/2”. I’m very satisfied with its performance. Still a little tweaking to do and figure out the best way to reduce the front and rear as needed, as well as a floor to raise the work piece a bit. Other than that I’m pleased with how the first attempt turned out.

-

Okay so here’s some pics of the 1/2. T is 3/4 reducing to 1/2. Mixing tube is 4”. Tip is .023 trimmed back 1/8”. It’ll fire at 3PSI and turn up to 30 PSI without spitting, sputtering or puking gets really hot and actually heats the chamber better than the 3/4 flame has a bit of a green tint so looking for advice. Thanks

-

Yeah I really like the T for the simplicity of the build. Just starting out I’m going to initially do stock removal for simple blades and work up from there. Wanna be able to heat treat,etc. I’m sure I’ll start dabbling in moving steel sooner than later. Never been the patient type. Makes me wonder how I spent half my life as a cop and stayed married 32 years. LOL

-

Will do. Started building the 1/2 and realized one of the fittings was packaged wrong. After throwing stuff while the wife laughed at me, I fired the 3/4 inch and threw an old blade from my zero turn in it. Heated to non-magnetic in around 4-5 minutes or so running at 8 PSI. Still wanna experiment with the 1/2 though.

-

Oh I understood you Mike. I did adjust a few things and it seems to have worked. Going to run it a little more this weekend and see how it goes. I did pick up the materials and will most likely build the 1/2 burner and test it as well. That way I can see which is going to be the best and safest application.

-

Thanks Frosty. Do you think the 3/4 T burner is too big for 226 cubic inches? I fiddled with shortening the .035 and adjusting the depth of the burner inside the forge this afternoon. Fired it and ran it at 10 PSI for about 10 minutes and it seemed fine, no flame creeping out of the burner holder. I did pick up parts for the 1/2 inch just in case.

-

Thanks Mike. I think I’ll build a 1/2 burner. Based on info here I know the mixing tube should be 4 inches and I’m assuming a 3/4 to 1/2 reducing tee. What mig tip size would you recommend?

-

It lights at the output end of the burner. The rear exhaust port is 2”X 5”. This was before applying the Satanite.

-

Hey guys, another newbie here. I just heat cured my forge. Dimensions are 226 cubic inches. Shell is a helium tank, 2 inches of kaowool, 1/4 inch Satanite. Burner is a 3/4 inch T burner built to Frosty’s instructions. Running s 30 PSI regulator. Burner collar/holder is 11/4 inch. It lights and fires fine but here’s my concern. I noticed a “dragons breath” emitting Faron the forge following the burner tube up and out of the holding collar which is set 2” off TDC. Obviously this is not a good thing for many reasons not to mention the wife being mad if I blow our workshop up. Any help is appreciated.

-

Frosty et al, Been lurkig for awhile to gain knowledge not available on YouTube. Tonight I tested my first ever T burner based on the instructions provided. The ONLY difference was not having the availability of Tweco tips so I went with another (same size). Once fired it seems to burn well. Nice blue flame, just a little orange feathering at the tip. This was a test outside of the forge, I’m finishing it tomorrow. I’m running a 30 PSI regulator. Here’s my issue. If I attempt to light at the end of the nozzle it chuffs out. Lighting at the jet it starts right up. I’ll try to post a video tomorrow just too old and tired right now. Any suggestions are appreciated. Please don’t yell, I’m a retired Homicide detective now working domestic violence for the DA/SAO so I have a fragile personality. Thanks! Rich