-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by FinnOnTheTank

-

-

-

My scrapyard has shopping carts full of coil springs. I’ll probably go by there Since it’s .50¢/lb for steel.

-

Thanks for all the ideas guys. I’ll get some steel to work with for the tools soon. I just found a steel yard close to me. All I have is a few pieces of hot rolled steel from Home Depot right now.

-

I’m not sure if this is in the right section of not. Please let me know so I can put it where it needs to be.

I am brand new to this. I’m trying to figure out where I should start, and what I should make first. I have an anvil, a forge, a vise, and hammers. What tools should I start first? I have no tongs, or chisels, or anything else for that matter.

-

I think that leg got banged up enough for a pass. Haha. I did catch the other shin on my horn a few weeks ago.

-

Thanks for the input Thomas and Frosty. All I was thinking about was something heavy. Not weighing something down with my own body weight. Lol. I need as few trip hazards as possible. I trip around enough since my left leg is a prosthetic below the knee.

For the anvil tie down all I need is the chain and to make the brackets.

-

Frosty, I wanted to do the router idea before. But I have no router and don’t know anybody with one. I don’t have a drill press yet either. The only tools i had before i started venturing into blacksmithing last month were automotive specific. I only have a little 60lb anvil right now, so I’m doing the wrapped chain attached to L brackets by and eyelet bolt. When I find a larger anvil I hope to have a router by then and I’ll probably do the depressed fit then.

I do like the idea of keeping the tong rack a little mobile. I plan on making some form of hammer hold for the stump. As for my vise I still have to make a stand for that. I’ve seen people make a portable one with a semi truck brake drum. That may be the route I take.

-

I already have the stump lined out and I have 2x4s screwed together around it to guide the chainsaw. It’s a large piece of white oak. It’s about half a foot too high right now. After I cut it I’m gonna smooth it a little with a belt sander. I already cleaned off the bark, and I plan on making some iron bands to put around it and hopefully minimize the splitting. I might use the remaining piece of log to gorge on since it will still be significantly thick. Maybe use it for forging bowls or the sort.

-

Thanks for the advice VaughanT. This is my first forge. It’s going to be an ever evolving project. I already planned on upgrading the corner posts later on with some stronger angle iron and also adding a rack for tongs. I’ve also found a half good that fits perfect for the cart. All I’ve done is heat up a 1/2” square rod in a temp forge so far. I just tapered the end and put a 90* bend in it. I almost have my anvil set up. I just have to borrow a chainsaw from my step dad when I see him in two weeks to get the log to the right height. After that I should be ready to really start.

-

-

11 hours ago, Frosty said:

no reason to quote the entire preceding post

So should I just have it under the firepot, or make it fit the whole tray? If I make it fit the whole tray, then it will be more flush. I feel like doing just the perimeter of the firepot is going to get annoying since the firepot will be sitting up a lot farther than the tray, so scraping the coal in won't be as easy. I'll probably just use a utility knife for it, that way I dont have to deal with a ton of dust.

-

1 hour ago, Irondragon Forge & Clay said:

If you have a store that sells wood stoves near by, they sell insulating boards to put under them and are easy to trim.

I'll have to search for it around here in Georgia.

-

13 hours ago, Frosty said:

no reason to quote the entire preceding post

Thanks for the advice! I was wondering if i would need to insulate it. I just looked up the cement backerboard and I'm not seeing many that are smaller than 3'x5'. I'll have to find some that are smaller

-

On 7/13/2018 at 9:14 PM, iron woodrow said:

no reason to quote the entire preceding post

Scrap pile find? You are officially the luckiest man alive.

-

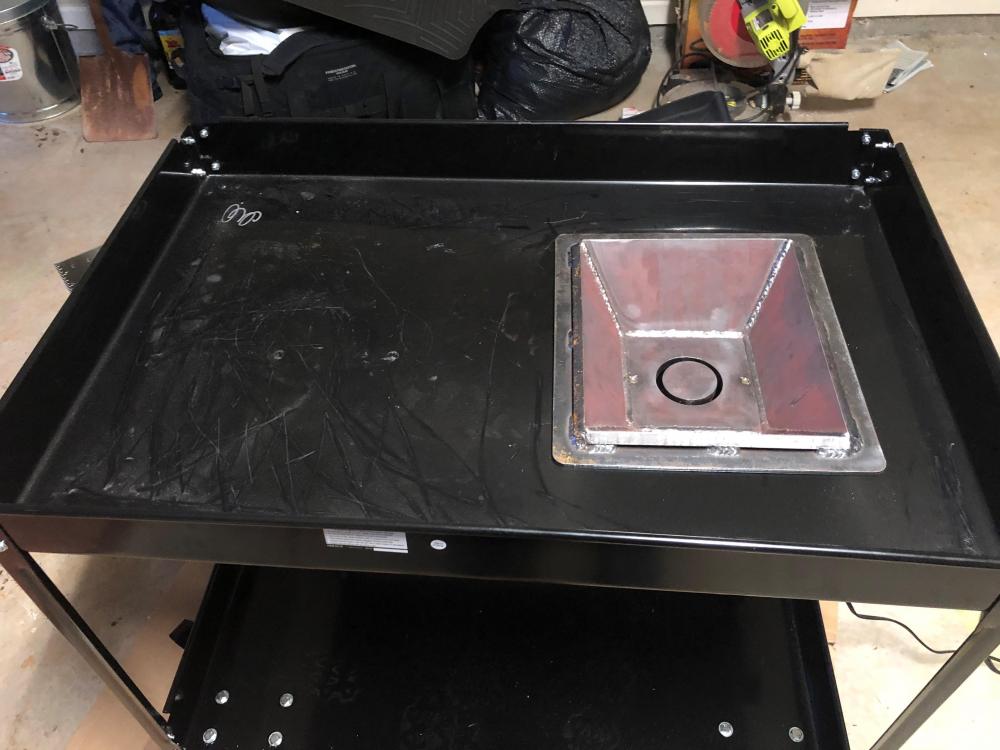

Since I will be moving into a new house soon I needed a forge that was portable. I'll be forging outside under a canopy until I'm able to build a shop/storage shed. I used a firepot from Fiery Furnace Forge, and a $55 36"x24" service cart from Harbor freight. I'm using a hair dryer for a blower right now until I can afford a hand crank blower. I do plan on cutting down some of the walls later on if i end up forging larger pieces. After a few uses im going to assess everything, and i may end up welding in a frame on the buttom of the top tray for better suppoer of the firepot.

-

1 hour ago, ThomasPowers said:

Looks like a lot of rebuilding on it; what's the rebound test numbers for it?

For my first anvil it was a good price to start with. Rebound is close to 70%. It's a better start than the harbor freight anvils for sure. I've found some other anvils at some antique shops around me, but for right now they are a little out of my price range. When I get settled in my new house in a few months I'll be forging a lot more, and wont have to worry about moving costs, etc.

11 hours ago, stevomiller said:I don’t know but did find this thread: Click here

A google search turned up other posts here and other forums concerning anvils with 6 point star in circle logo.

Thank you, hopefully I can find some more information.

-

This was the first anvil I came across when I first started getting into blacksmithing at the beginning of July. It's 60 pounds. I haven't been able to figure out what brand it is, but it has really good rebound. For a first anvil it's not too bad. If anybody knows the brand I'd appreciate some feedback.

-

On 7/31/2018 at 11:40 PM, Daswulf said:

no reason to quote the entire preceding post

I'll be using it for sure. I should be moving into my new house withing the next few months. I won't be doing much forging until we've moved. Right now im making a stand for my anvil.

-

4 minutes ago, Daswulf said:

Nice vise. What'd ya pay for it if you dont mind my asking?

$150

-

A couple weeks ago I went out looking for a post vise. I hit a few antique shops and didn't have much luck. I left a note with the largest antique shop I went to. 2 hours later an older man called me and had this. An old Iron City vise. It's a little over 5 inches. I cleaned it up with a wire cup and BLO. The next project is building a stand for it.

-

I love this idea. I may have to take some cues from this design.

-

I fired up my forge for the first time tonight after building it. This was all unplanned because i don't have my anvil mounted yet. With my anvil on the ground I practiced tapering a little bit. Also, I practiced bending a 90* angle over the edge. I guess I'll use this to move around coals after I cut a little bit off the other end.

What should I make first?

in Tools, general discussion

Posted

To make some S hooks.