jack hollingsworth

Members-

Posts

90 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jack hollingsworth

-

From the album: jacks things

-

another pic, it has since been glued and now im waiting to get a go with the stainless mig at work so i can weld on the butt cap (the stick tang goes through a hole in the stainless because i had no access to a tap and die set) The blade is W1 by the way and the fittings are 316 stainless. The handle is called Kwila, it is a Papua New Guinea hardwood. I cant wait to start shaping the handle, ive been busy doing long hours at work.

-

Tanto style second knife

Images added to a gallery album owned by jack hollingsworth in Members Gallery

-

From the album: Tanto style second knife

-

thats such a nice blade Rich, i like how its not so "busy" or complex, its refreshing. How do you secure the handle on? is it peened at the end cap or some other method? Do you have a picture of how you put the billet together to start off with that you could post?

-

-

hello all, Here is my second knife so far..

-

From the album: Tanto style second knife

-

From the album: Tanto style second knife

-

From the album: Tanto style second knife

nice fit! -

From the album: Tanto style second knife

-

From the album: Tanto style second knife

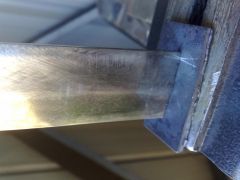

the stainless steel gaurd after polishing -

From the album: Tanto style second knife

forged to shape -

From the album: Tanto style second knife

blade after polishing -

From the album: Tanto style second knife

the blade after polishing -

From the album: Tanto style second knife

looks about right so far -

From the album: Tanto style second knife

the guard, hot punched and filed to a pretty good fit! -

From the album: Tanto style second knife

after heat treat and tempering -

From the album: Tanto style second knife

after heat treat and tempering -

From the album: Tanto style second knife

trying the heat treat with the clay method -

From the album: Tanto style second knife

ground after forging, ready for heat treat -

ok did a search on the website and got the answers i was looking for. http://www.iforgeiron.com/forum/f52/fuller-13311/

-

hello there, I have a question thats been nagging at me for a while. How do you put a "blood groove or fuller" into a blade, do you forge it in or have you got some stock removal method.. The ones that i have seen look so perfect that it makes me think they could have been milled or something. Anyway if anyone can help i'd appreciate it. Cheers.

-

hello, this is my first forged knife, its made from half of a nicholson file i found. forged to shape in my 'wok forge'. The bolster is actually a chunk of black plastic.. I dont think i would use it again, but it worked fine for my starter knife. Copper spacers (i found that too) and a mystery wood that was in my shed when i moved in. If you know what wood it probably is please let me know as i dont know much about wood. The but cap is mild steel (welded on). I know its bent. I didnt plan on that and probably should of fixed it before i heat treated it but i was impatient and my weekend was running out. Overall, though, im happy with how it turned out. I know what works and what i have to focus on more for the next one. Let me know what you think, and what type of knife it is! Alot more pics in my gallery first knife project - Blacksmith Photo Gallery