Toolgal

Members-

Posts

25 -

Joined

-

Last visited

Profile Information

-

Location

Gainesville, Florida

-

Interests

19th - 20th century tools: farming, turpentine industry, woodworking, blacksmithing, and others, including handmade tools. Museum collections management and object care.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Depends on if it is on the floor or on the workbench. Great discussion guys! Yes, the proper name is always what I am looking for but picking up all the other info is a bonus!

-

Hi All, For once I don't have a question, but I thought some of you might be interested in this - On the Blacksmith Wikipedia page (https://en.wikipedia.org/wiki/Blacksmith) and the Forge page (https://en.wikipedia.org/wiki/Forge) both say they need some help confirming and/or adding to the information they have. I realize that Wikipedia is not the authority on all subjects; with info from the general population you always have to beware of incorrect attributions and misinformation. Be that as it may, they could probably use your help on these sections. If anyone has a desire to share good information and wants to write or edit some sections click on either of those two links above. Happy Writing! Tool Gal

-

Who made these diagonal pliers?

Toolgal replied to Toolgal's topic in Tools, ID, and pictorial reference

Thanks to every one who chimed in on the Imhoff connection. Slag, did you know that if you type John Imhoff, Chicago Pneumatic Tool Company into Google your quote from this site comes up as the second hit? Woo Hoo, you are famous. Thanks all! ToolGal -

I was going to have to make a big decision, was it a center drill, like Biggundoctor and others said, or was it a countersink bit, like Das Wulf and others said? Two pretty worthy camps to have to choose from. Thank heavens Marc1 spoke up and confirmed my belief that bits can be used for a variety of things. I took my image and added a countersink bit and a center drill, and it's pretty hard to tell the difference. I have a few tools called Screw Hammer Wrenches, so perhaps this will be called a Countersink Center Drill? Take a look at the three bits together. If you see a difference between them please let me know so I can differentiate. That leads to a question I still feel comfortable asking due to my Newbie status - why are some bits called drills? To me a bit is not much good unless it is attached to the drill. Why are some bits called drills?

-

I'm not surprised, they are really beautiful. I had never seen cooper's tools prior to working in the barn; they are the first group of tools that sent me to YouTube to see what they were for. You probably know that the tool with handles in the top left of that same photo is a pit saw box. That one had me stumped for awhile too. Obviously it wasn't the box the pit saw came in! Once I learned how a pit saw worked it was easier to understand what it was for. Couldn't it have just been called handle?? Live and Learn, ToolGal Fire is always always a concern, yes there is a fire suppression system in place and the fire station is less than a mile away, but that doesn't mean I breathe any easier. Gainesville is known as the lightning capital of the country (I think every state has one of those places ). So lightning strikes are always a threat. We are currently in hurricane season until November, so for now my biggest fear is that the barn and I will get scooped up in the wind and deposited somewhere far, far away. As Roseanne Roseannadanna used to say, it's always something!

-

They seem to be fairly unusual I can't find another set exactly like that one. You're right that they are sort of like an off-set seamer, made to accurately bend metal but it doesn't seem that the bits could close forcefully enough to get a decent grip. With that high arch just before the bits I thought they might be might be fire charging tongs to place things into a crucible, but the bits meet more like an anvil than a pincer. Another thought is that they are box jaws tongs, but again the jaws don't meet in a way that would hold things. Clearly help is needed! Thanks very much, again. ToolGal Sorry, I was replying to a comment Daswulf made about a set of tongs, T284, in one of my photos. I didn't want to leave everyone else wondering what I was talking about.

-

I couldn't agree more about the peg board and pine, neither are known as materials that are friendly for longevity. Preservation is a delicate balance, what I weigh is the duration that the objects have been in the environment vs. how they will react to a new environment. Anything that is made of more than one material already has structural problems in a poor environment, parts of objects expand and contract at different rates so they are always in some sort of moving state. In a framed painting for example you have the canvas, the pigment, the frame, the framing hardware, all dealing with the temperature and humidity they are stored in. I always imagine a "push me-pull you" sort of thing going on. Of course we want to rush these objects into the perfect climate, that's in our nature, but sometimes that is exactly the wrong thing to do. My board offered to add air conditioning in the barn but I turned them down, I don't think the building would stand up to that much change. Putting tools, let alone a building, that have somewhat acclimatized to a poor environment into a totally different one sets them up for self-destruction. Replacing the peg board is already on the list, I'm not thrilled with anything sitting on wood, so the shelves will have to be dealt with too. The main thing I can try to provide for them is stability, along with the oiling and cleaning that you mentioned, that is an ongoing chore that I am happy to do. If the environment doesn't last 500 years I won't be worrying about hammers and saws.

-

This one should be easy to figure out, but I can't find an exact match so I am, as always looking for answers in all the right places. It is a double ended bit, one end has a slight point, which I suspect is a nail starter hole tip, the opposite end has no such tip. Each end has what looks like a small channel in it that makes me think that the bit removes the wood as the it turns, somewhat like an auger. Because it can be flipped around to use either end I am tending toward an electric drill bit, but I really need more of a name. Any BIT of info would be appreciated. Tool Gal

-

I have thrown some pretty difficult tools out to you and you've done a great job figuring them out. Now here's what should be an easy one... I have some diagonal pliers, fairly ordinary, but they have a maker's name (I believe) on the side of the handle that I am unfamiliar with. It looks like IMMOFF & LAN or IMHOFF, I'm not sure. I can't find that maker's name in any of my reference books, nor can Google help (again), If anyone has heard of pliers made by this company please let me know. Thanks very much. If you are more interested in ID-ing photos than discussing makers, I have one for you, check the next post. Tool Gal

-

It has been suggested that I post some photos of the barn where I work, so here you go. I'd also like to let you know how important the contributions you have already made are, not just to me, but to the world. In the museum world absolute accuracy is the standard we try to hold ourselves to, that's why I am consulting my team of experts (y'all) for the names of these tools I can't ID. Museums as a whole are one of the most trusted institutions that offer educational information, so we don't like to screw up. Identifying these tools is great fun, so is the banter about their possible uses; I can tell some of you are having a good time with it too, but I want you to know that I consider your contributions worth more than gold. Most of us museum folk consider what we do in caring for objects to be a stewardship, we are saving our history one piece at a time in order to educate future visitors. Many of us work behind the scenes conserving, stabilizing and preserving, making sure these objects last at least 500 more years. Few of us make much money (except the directors) but we have the satisfaction of knowing that we are doing important work. The things you tell me about the objects gets recorded and added to the catalog, along with measurements, lengthy descriptions, photographs, past usage, its condition with abnormalities noted, location where it came from and who it came from, and any other info we have. I like to add reference pages, videos, and any articles that describe a similar piece. Researchers can view our objects and information online from anywhere, so the thoughts you have shared with me could have circled the globe already and be a part someone's doctorate. Yes it is a bit scary. Here are some photos from my world.

-

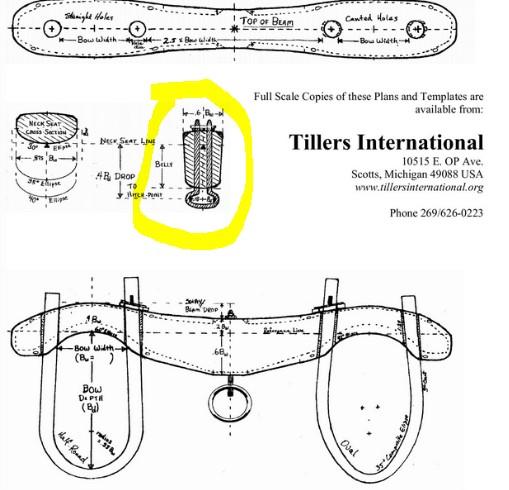

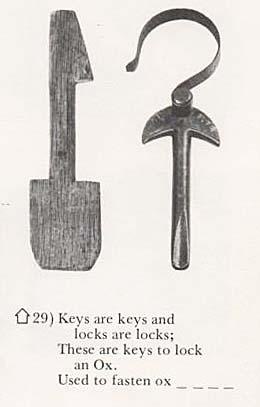

No, no wax but it sure seems shiny and buffed, doesn't it? That's one of the mysteries. Thanks for the Tiller's TecTalk article you sent, were you referencing the circled image below? Actually it is one of only two images I had already found that looked anything like my piece. The other image I found that first led me on this path may convince you a little more. It is from an old Yankee Magazine publication, Book of Whatsits (1975). Take a look. There are two versions shown, one wood and one metal. If you merge the two images you come out with something that looks a lot like mine. (Spoiler alert, the answer to the puzzle in the image is "bows"). Best, ToolGal Yankee Magazine pub. TA648

-

If indeed it is am ox bow key (and that really seems the right direction) I am curious why it is in such beautiful condition and like you mentioned, why it was made from wood. I do have some ox bows but they are obviously very well used. My object may have been carved just as a carving exercise, or perhaps the carver wanted to memorialize an ox bow key and use it as a paperweight. I understand this, I found an artist's drawing of my favorite tool, a turpentine hack on view at the National Portrait Gallery in D.C. Never thought that would be used as a model in a work of fine art, but I loved seeing it. If anyone could find a drawing or a video showing a key in use that would be great, I can't quite wrap my head around the attachment process. If there are other ideas for this wood item, I'd love to hear your thoughts. Thanks, ToolGal

-

This might be the hardest identification of all, but I know you are up to the challenge. It's not made of iron but I know many of you have a wide range of talents. I hope we can figure this one out. This was found among a batch of what I suspect are handmade tools, all beautifully done. It is 8 1/2 x 5 x 1 in. I don't know if the dowel or the arms ever moved, but they are stationary now. The other tools in the group are a molding plane, a block plane, a hammer, and a spokeshave. They all have the same wood type, carving marks and are well polished and seem unused. Of course nothing says that the company my tool kept had any relevance to what it is, but that is all the info I have to offer. My only thought is that it is some kind of "key" for an oxen yoke, I saw one in a book of weird tools, but it didn't explain its use. Thanks very much! ToolGal

-

This is not for cookie making!

Toolgal replied to Toolgal's topic in Tools, ID, and pictorial reference

Holy Cow, you guys are great! Not only did you figure out the rosette iron, you made me hungry at the same time. It took a little convincing to make me believe it was really a baking implement, it is fairly heavy and in pretty rough shape. I was thinking it could be another one of those implements that was made to be one thing but put to use in another way, who knows how. Just shows you that if it looks like a duck and sounds like a duck, it may really be a duck! JHCC put us on the right path and Farmall cinched it with the cooking site link, confirmed by the likes of Daswulf and BIGGUNDOCTOR, - yahoo! I appreciate hearing y'alls thoughts on what it isn't as well as what it is. I had considered many of the possibilities that were eventually discarded as well. Learning more every day. Gratefully, ToolGal -

With the tiny spoon taken care of I submit this next item for identification. It is labeled as a "Rosette Iron", which traditionally refers to an implement used in cookie making. One dips the iron into batter and then into hot oil. I don't think my tool was ever used for that purpose. The flat bottom would not be suited for making fancy cookies. Nor does it seem that it is a branding iron, it wouldn't make a distinct enough brand, I don't think. It may be something that is inserted into a similarly shaped hole and twisted, but for what purpose I have no clue. Looking for answers with thanks! 19 1/2 x 1 1/2 in. dia., Iron with wood handle ToolGal

PliersDiagonal1470.jpg.a5030664b3c0b92bbb513049c40ac659.jpg)