Ted Ewert

-

Posts

557 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Ted Ewert

-

-

Multi tong

in Tongs

I've seen various designs for tongs which will accommodate a variety of stock sizes. I thought I'd throw my hat in the ring with my own version.

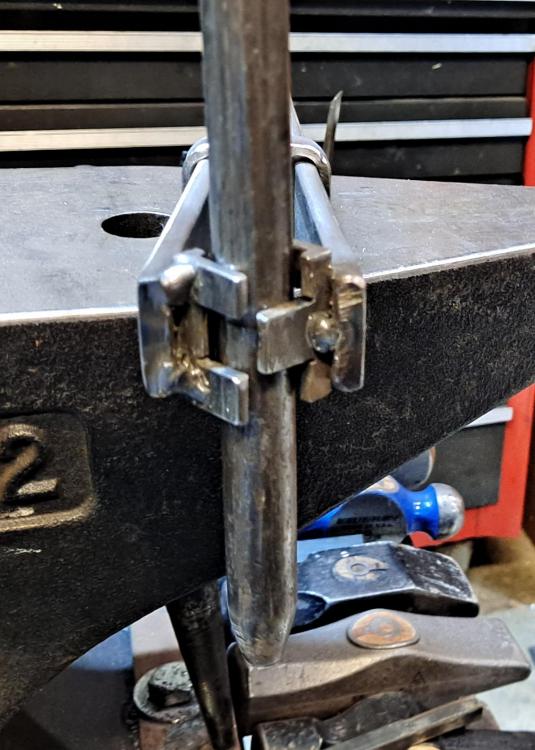

This prototype uses a piece of angel iron which clamps against a flat jaw. The angled jaw pivots and is self aligning with the stock.

This provides 3 solid points of contact with the stock, as well as preventing lateral movement.

I was frankly surprised at how solidly it held a variety of stock, from flat bar to round and square.

It will securely hold anything that fits in the jaws. The reins expand too far for the bigger stuff to be practical, but extending the jaws out further from the pivot point would mitigate that somewhat.

Although improvements could be made, this is a viable concept for a multi use tong.

-

1/4"-3/8" should give you enough material for the tennon, assuming a 1/4" tennon. You could always do a test piece to get more accurate.

Do you have a monkey tool to square up the shoulders? Easy to make.

-

I think it's easier to forge the jaws and boss on the ends, but whatever works for you.

Tongs are one of those things where many different ways to make them are possible, but tried and true works best.

-

-

Pat, I got one of guillotine tools a while back and they work OK. The problem I found is that the bolts will loosen up after a while. I finally got tired of it and welded it together.

I eventually built my own, which is completely different.

-

I'm using a simple "H" beam for the anvil on my hammer and it works fine. I don't think you'll have any problems no matter how you configure it.

The foundation is more important IMHO. That's where all the force is dissipated.

My hammer has a 40lb tup and it shakes the house. I have 8" of concrete below it which is not nearly enough. Should be closer to 36", or more, and isolated from the slab.

As to your anvil height that depends. I prefer to sit while using the hammer. I find it to be a more stable position and I can see what I'm doing much better. Easier on my back too. Otherwise you could check what the nominal height is on commercial machines and go from there.

-

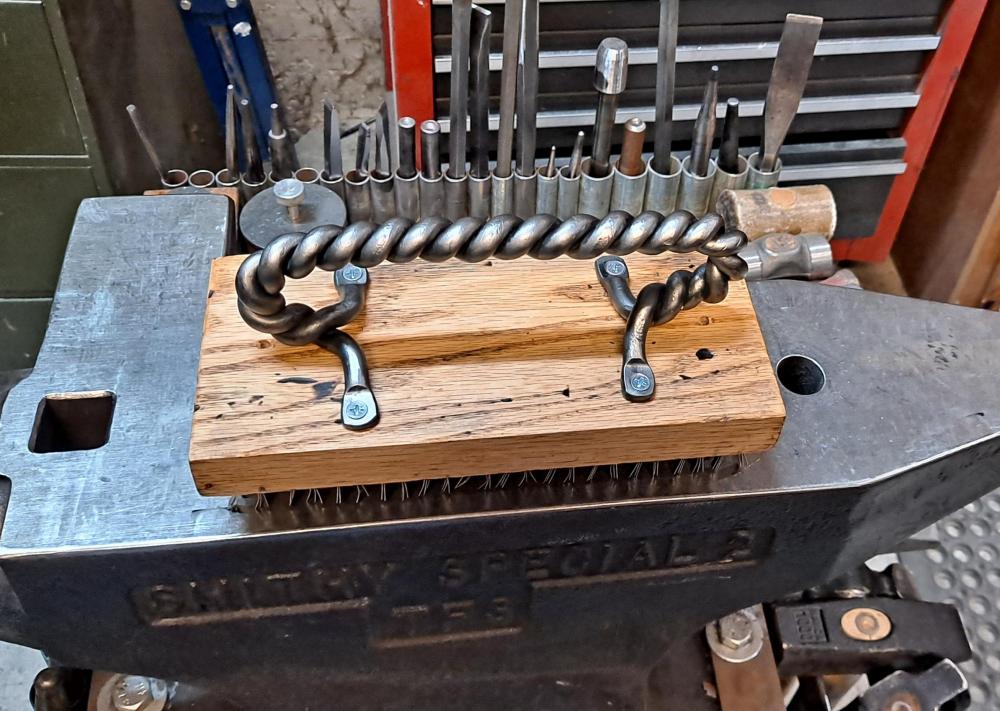

Globe looks good Pat. Nothing ever turns out as good as you want the first time (not even on the second or third for me). Nice tool rack.

-

I did, and that's what got me thinking. I still like yours better.

-

Is that a weed harpoon?

-

I just made it for fun really, sort of a challenge. It certainly wouldn't survive under the power hammer, but would be handy around a big piece of hot steel.

-

I've been thinking about different ways to make a punch holder. It had to be simple yet able to hold a punch securely. After several aborted attempts, I came up with this design. I welded two pieces of interlocking angle iron on the ends of a length of bent 1" flat bar. I squared up a slice of pipe for the keeper. It will hold anything from 1/4" to 3/4", round or hex.

-

Dennis CA, nice work so far. That beam looks heavy. I assume you get a fair amount of snow there.

How thick is the floor going to be? Do you have a power hammer, or plan to get one?

-

Yes it is. Works good and I use it quite often.

-

-

There's 1 inch between holes. That measurement was arbitrary. Also, the rods don't stay straight back after twisting. You have to realign the rods to move the jig back, which is easy while it's still hot. A piece of thicker stock would keep the rods straight.

-

-

-

-

Thanks for sharing that BD. I'm 65 and never did find that job I loved. Like you, I have a good paying job but it bores me to tears. I'm just waiting for retirement.

I don't think a particular line of work is necessarily the reason we're all here anyway. It helps to love your work, but sometimes our lesson is sacrifice.

-

The contactor assembly looks to be a European version as it's 50 cycle, 220v. As long as 220 volts going through the control system is OK, should work.

The minor damage doesn't look serious unless it cracked the casting. It's just an insulation flange.

You've done an amazing job at resurrecting an old rust bucket. I look forward to seeing how it works.

-

PB, I hear you about the hobby part. The fun for me is getting a wild hare idea and then trying to build it. I rarely build duplicates of anything.

I'm a blue collar guy living in a very affluent area. If I had the skills and ambition I could do quite well locally. I've often been tempted, but I'm afraid it would take the joy out of it. Blacksmithing is my escape, as well as a creative outlet. Those two things have more value than money to me.

-

-

14 hours ago, Haywood71 said:

Ted, I am using James Batsons book "Build your own hydraulic forging press"

Thanks for the heads-up.

-

Frosty, TW. Chickens running without a head really throws a wrench into the brain controls everything theory. Running is a highly coordinated action requiring balance. Random nerve impulses cannot account for this.

Multi tong

in Tongs

Posted

This jaw handles all small stock except 1/4" round. It will even grab 1 1/2" flat bar. The variety of interchangeable jaws is numerous. You could make square channel jaws for particular widths of flat stock for example.

For an improvement, I would make the flat jaw longer. I would also make the curved jaw a bit wider and thicker. That way it could be moved further out.