Ted Ewert

-

Posts

557 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Ted Ewert

-

-

I used to play golf, but it was too easy and cheap compared to blacksmithing.

Owning a house pretty much eats up the rest of my spare time besides work. There's also my son's house, the mother-in-law's house, all the cars...

If you're handy, friends and family will always have work lined up for you.

-

Our facilities building has copper air lines running all over the place. Best way to go for permanent air lines IMHO.

What size air compressor do you have Roger? Do you have any equipment running on it, or is it just utility air?

-

Getting the two halves goofed up is a mistake many of us have made. I know I sure have.

I follow the three left turns method for my set downs to avoid that problem.

Tongs take some practice to get right. Each set you make will be a little better than the last.

-

Really nice shop Roger, I'm happy for you. Love the oak framing.

Wood isn't really a big fire hazard. It takes a lot more than a little flash fire to start, and continue burning, thick wood.

I assume you buried the power lines out to the shop? What size service are you installing?

-

I've had a Dremel tool for years, very handy. Never done any polishing with it though. I use it mostly to grind the corn off my foot.

A carbide drill bit would probably work, but then I'd probably have to get carbide tap too. My wallet's feeling lighter just thinking about it.

-

George, threading did occur to me. However, I can't drill a hole in a ball bearing without normalizing it first, which then gets back to the finish. If it was a mild steel ball threading would have worked great.

The application also doesn't warrant a lot of strength. The small impact pushes the bearing back against the socket, which provides ample support. The epoxy merely keeps the bearing in place.

Nice progress John. Tongs are a great way to improve your skills.

-

13 hours ago, JHCC said:

Now I’m thinking ball-and-claw….

I spent a lot of time thinking of different ways to attach the ball. The main obstacle for me with forging around the bearing is heating the bearing to the point where it changes color. How do you then restore that bright shiny surface?

I don't have the polishing expertise or equipment, so I opted for a cold attachment.

I'm sure that the knife makers here would have no problem with it.

-

Thanks all. George, I wound up holding the bearing in with epoxy. I welded a piece of wire on the bottom of the bearing to anchor it in. I wanted more of the bearing exposed than a wrap would allow.

-

-

3 hours ago, SinDoc said:

Ted, I think I would kill to have your climate lol. It has been 88-94 degrees here for nearly 2 weeks straight and the humidity has not been kind either. I think our weather is supposed to finally break and cool back off into the 70's next week. This summer has been a hot and sticky one.

When it warms up in the central valley of California, the hot air rises. This pulls colder air from the ocean inland, which has to go right by my house to get there. Free air conditioning!

The downside is that it has become quite popular to live here, driving property values to ridiculous levels. I also find that I don't have much in common with my neighbors anymore. Too much money can spoil a place.

-

We're having a bit of a warm spell out here on the left coast. Must have gotten up to at least 78 degrees today. I almost had to open a window.

My shop is in the garage, which is under the house. It's always cool in there no matter what the weather is like. I have a couple of speed controlled 8" axial fans mounted through the wall to move heated air out.

The pacific ocean is just over the hill from my house. I'm close enough to get the sea breeze, but far enough to avoid any salt air.

This area is designated as having a "Mediterranean climate", which is a perfect blacksmithing climate. Rarely too hot or cold for the shop.

Yes, I am spoiled weather wise.

-

We sometime fail to realize that most people are completely unaware that blacksmithing is still alive and well. I'm still pleasantly surprised at the reaction I get from handing someone a simple bottle opener.

Computers and robots are bound to replace some of the workforce. Humans are still far more adaptable and capable at complex tasks. Humans are also infinitely creative. You can't get that out of a robot.

-

No, but that's a good idea, especially for a little girl. Thanks.

-

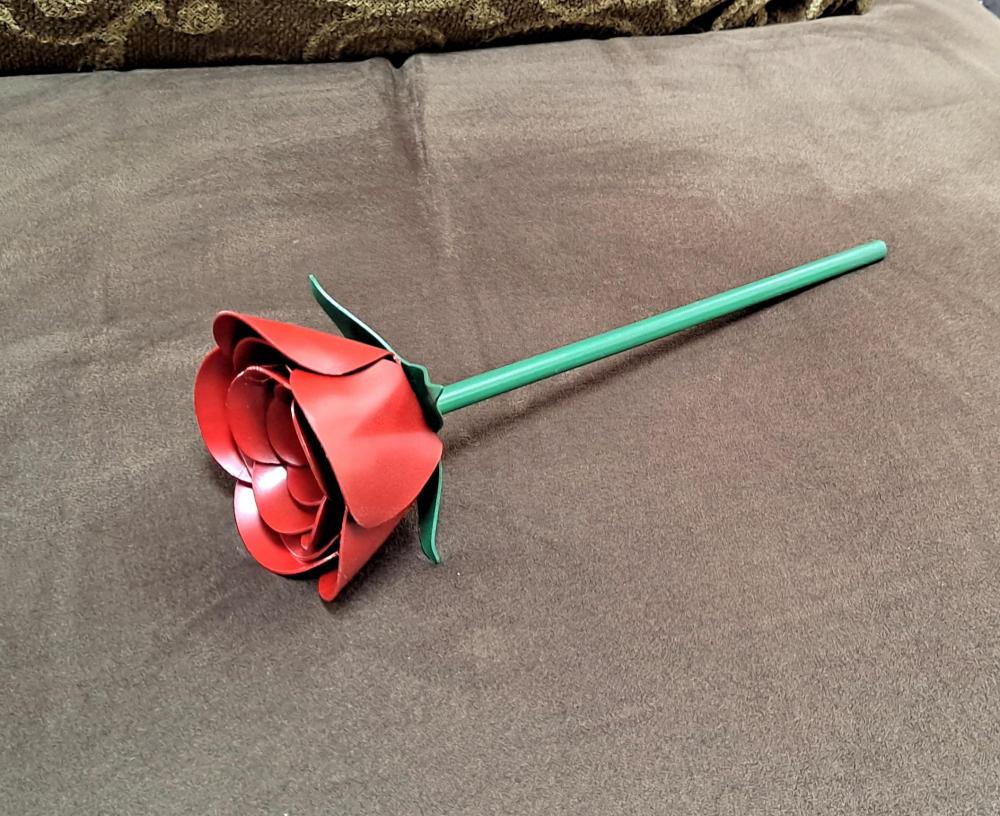

I made this rose for my granddaughter using a no heat method.

I bought the blanks on ETSY and they work easily without a torch. The petals are formed in a swage using a ball peen, then bent using pliers.

The stem is cold peened in the vise on one end for a stop. All the pieces are then painted.

When the paint is dry, everything is epoxied together. I put a little piece of tape over the stem holes before painting to give the epoxy a grip on bare metal.

This method allows for more creative paint schemes, and it's much easier. The green on the stem is a much more natural color than what is depicted.

-

-

I see that the affliction is not unique to Croatians.

Sometimes there's a fine line between humor and a clinical concern.

-

I would guess painted wood, they're just props.

I'll ask my daughter to send me some more pics.

-

My daughter recently returned from a trip to Croatia. While there, she went to a Stuffed Frog Museum (that's my daughter!).

Evidently, some guy spent half his life stuffing frogs and creating little scenes where these frogs replaced people. She showed me the pictures and it's hilarious. School rooms full of these frogs.

Anyway, one of the scenes was a smithy. She knew I'd get a kick out of it.

-

The wife wanted a pair of large leaf hooks for a charity auction she's involved with. These are made from 1/2" × 1" bar. Hooks are 2" dia.

The piston in my hammer cylinder decided to part company with the shaft during operations. Surprisingly there was little internal damage. Reattached it with some locktite on the bolt and it works fine. Cheap Chinese parts aren't worth the initial savings.

-

When I first started, I welded reins on some gas pliers for tongs. I still use those occasionally.

Harbor Freight has cheap extended grip pliers which also work. A 2 lb HF sledge hammer is still one of my favorite hammers. It doesn't bounce like harder hammers, which I find more controllable.

Hammers are like golf clubs: if you find one that hits straight, use it.

-

In my opinion, synthetic lubricants are far superior to their mineral based counterparts. Less friction, longer life. A bit pricier, but I doubt you'd ever have to change it.

Is that motor a three phase or single?

I'd love to drop by and use that machine, but it would be an unusually long drive from California to get some pipe threaded.

-

SinDoc, I've used circular saws for years and haven't had any kickback issues. Worm drives are particularly stable.

I don't own a chainsaw. For cutting up smaller trees and branches I use a Sawzall. Cuts like butter, no kickback and a lot safer and quieter.

-

Boy, that thing is working nicely. Great job on the refurbish.

Lots of oil.

I could use one of those for a gas plumbing job I need done. I still want to see it twist some steel.

-

.jpg.8d1827457be79060f7ed6ee0ea65d99b.jpg)

4lbs Steeled Wrought iron modified Swedish hammer

in Hand Hammers

Posted

Great looking hammer! I like the acid wash look.