jlblohm

-

Posts

196 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by jlblohm

-

-

I havent gotten that far in AIA (my library got it on loan from another library for me) but i skimmed through the book and i found the fisher pattent and i see the thin middle and thicker edges. Im sure the thicker edges helped with the major chipping the vulcans had.

-

-

Is it as thin as a vulcan?

-

On 2/14/2018 at 8:58 PM, foundryguy said:

i know little about the step and hardness. My plan is to harden the first batch to one hardness level 52-55 Rc. That process cost $1.00 per lb at best. I need simple and quick as things are very busy. To be clear, I am a life long foundryman, not a blacksmith!

Can you get the hardness above 55HRc?

By the way i like the thick heal. Reminds me of a Brooks.

-

Here are my anvils the first 2 pictures are my vulcan number 10 and the other one is an anvil i bought im hoping to get some more info on.

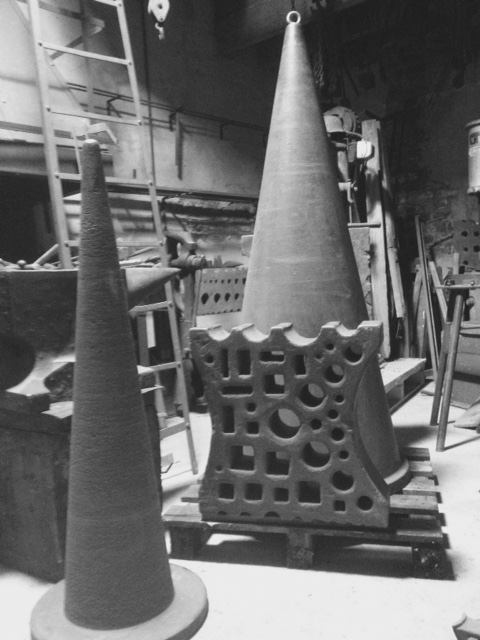

On 2/14/2018 at 3:51 PM, foundryguy said:Just cast, annealed and machined. H13 tool steel to be hardened to 52-55 RC this weekend. 85 lbs, made in Michigan! We will polish the horn and drill the hole in them tomorrow.

I dont live too far from you. I have been considering one these. I seen your craigslist ad. Im waiting to see the 200 and 400 #ers. Kinda hoping to see a double horn. You should join Don Foggs place. https://www.bladesmithsforum.com/ they like people to use there real names though.

-

On 8/7/2017 at 4:25 AM, jabbeke8 said:

This topic got really far off track but to get back on topic would you have any info on this anvil i bought.

-

I would just use it the way it is if i didnt have anything else to hammer on. That big crack is the forge weld failing. Its kinda interesting to see it like that and still have the horn attached. They were welded together from several pieces. I just sold one not too long ago with the heal snapped off but it still had good rebound. For what you paid for it and some steel i would say you got a good deal.

-

Fisher tops are 3/4 of an inch thick so you shouldnt be welding on any cast iron with that small repair. If i was to repair it which i would do some serious thinking before i did but i would only preheat the hardie area with a torch and be quick to do really short welds and dont focus the welds in one area, kinda jump back and forth from one edge to the other. Try not to get the surrounding area over say...500°f to not effect the heat treat of the face.

What should I do with this Mouse hole?

in Anvils, Swage Blocks, and Mandrels

Posted

This was posted on bladesmithsforum.com by Owen Bush im sure its here somewhere. I figured it would help if you decide to weld it up.

http://www.anvilmag.com/smith/anvilres.htm