-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by gaswizard

-

-

-

If you can pick her up with base over your head it is yours

-

-

8 hours ago, Salem Straub said:

Did you get that hammer up in the Seattle area? There was one for sale on CL there a few times over the past 3 years....

I've spent a decent amount of time running a friend's 100 lb. Howe, a very nice solid and controllable beast to be sure.Yes I did and trailered it down to Nor-cal. Love to see pictures/video of your friends 100 lb Howe to see how it is set up. Thanks for sharing

-

On 4/14/2018 at 8:20 AM, marcusb said:

IIRC the Late Great Grant Sarver started out with one. There might be some nuggets of info in his posts.

Marcus, I will check out his past threads. Looks like he was a longtime member with thousands of posts. Thank You for the lead.

Cheers

Paul

-

21 minutes ago, Frosty said:

Can't you just buy a piece of 5" thick nihard rubber and cut the pieces? Freeze the rubber in an alcohol and dry ice bath and a hole saw will go right through it.

I just did a web search and see NiHard isn't used for the rubber I'm thinking of cir. 40 years ago. The rubber I'm suggesting is the same thing they use to make rubber stoppers for lab glass wear. It's dense, hard but elastic and very chemically resistant so you can lube your hammer to your heart's content without fear of the oil eating the cushions.

These machines were built in a day that didn't use specific only one will do, parts to repair. I'll bet you can get away with stacking slices of old tires or maybe even wrapping it with glued inner tube strips.

It's like restoring a model T, pull the engine apart and discover it has raw hide or gristle for main and journal bearings. This stuff was meant to be repaired with field expedients.

Just saying.

Frosty The Lucky.

You are probably onto something. I know I can shave and sand down the rubber down to fit the hammers needs. I will investigate. Thank You

-

-

15 hours ago, Judson Yaggy said:

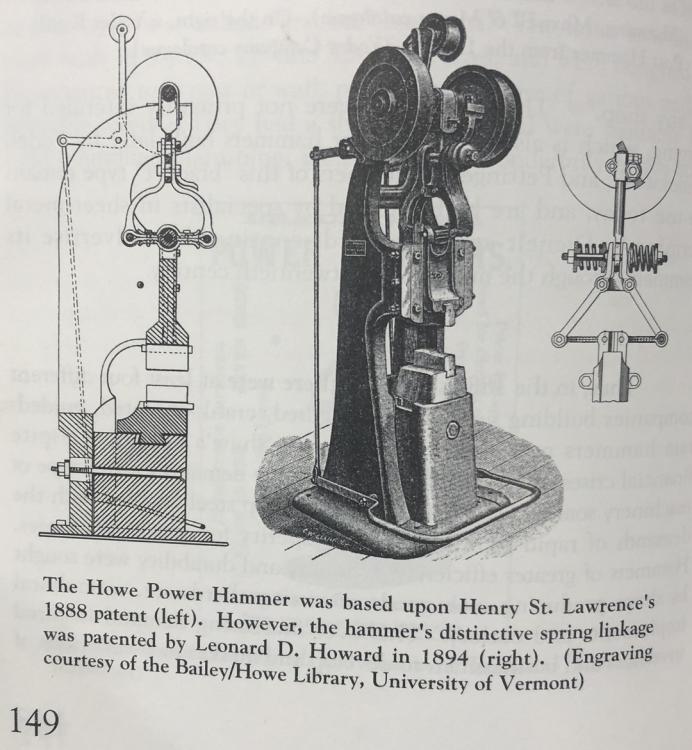

Really rare hammer! They were built not far from where I sit, and even here in the NE USA where there are a LOT of antique mechanicals I've never seen one in 25 years of smithing. Good score. The linkage is similar to the Bradley Compact hammers or Kane & Roach, try looking up those brands for info on tuning. There are still rubbers (springs) available for similar hammers from Cortland Machine (the surviving Bradley dealer) and several hammer rebuilding experts who mostly hang out on Facebook. Can't post links here, it's against the rules.

University of Vermont has a rare book section called the Bailey-Howe Library, if I recall it was partly endowed by an industrialist family from Rutland.

Judson, Thank You for the info. Going to get on the horn pretty quick and track down the company name you sent over. Will keep you posted. Cheers Paul

1 hour ago, patrick said:What a cool hammer! Thomas did contact me about this since I am running Bradleys which use a similar rubber cushion system. I did not have to replace my cushions but when I was looking into options for that (just in case I would need to) I found most sources to be quite expensive. I believe Bob Bergman can get them, I'm sure that the folks at Cortland Machine in New York could also do it since they supply parts, including cushions, for Bradleys. I know that Stuart Giesler had some new old stock cushions for Bradleys available at one time. I would measure the ones you have and compare with what he has. You might be able to modify the Bradley cushions to fit your machine. Another method is to make your own. I have heard that RTV pourable resin works very well in this application. I would contact Ray Rybar, a very talented knife maker, for info on this product and the process he has used. I'm told he's made new cushions for quite a few Bradleys with this product and has had very good success at very reasonable prices. Good luck.

I thought about making them. I have a pretty big vulcanizer and can make the tooling for the cushions but if the parts exist and can save me some time great. I will contact Ray shortly. Thank You for the info. Cheers Paul

-

22 hours ago, ThomasPowers said:

iforgeiron.com ==IFI

You will have to do your own digging here I'm about to sign off work and head to church. Unfortunately the cushion post was not for the same hammer as yours; but if they will make cushions for one; good chance they will make cushions for another.

Sent an email at the last known address I have for a friend who had to get new cushions for his hammer rebuild.

Thank You Thomas for the info.

When I get closer to the rebuild and installation of the Howe I will post something up.

Cheers, Paul

-

1 hour ago, ThomasPowers said:

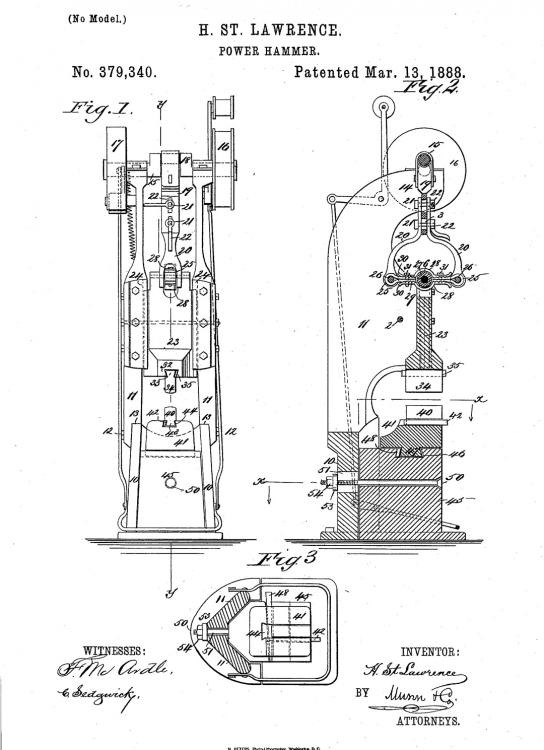

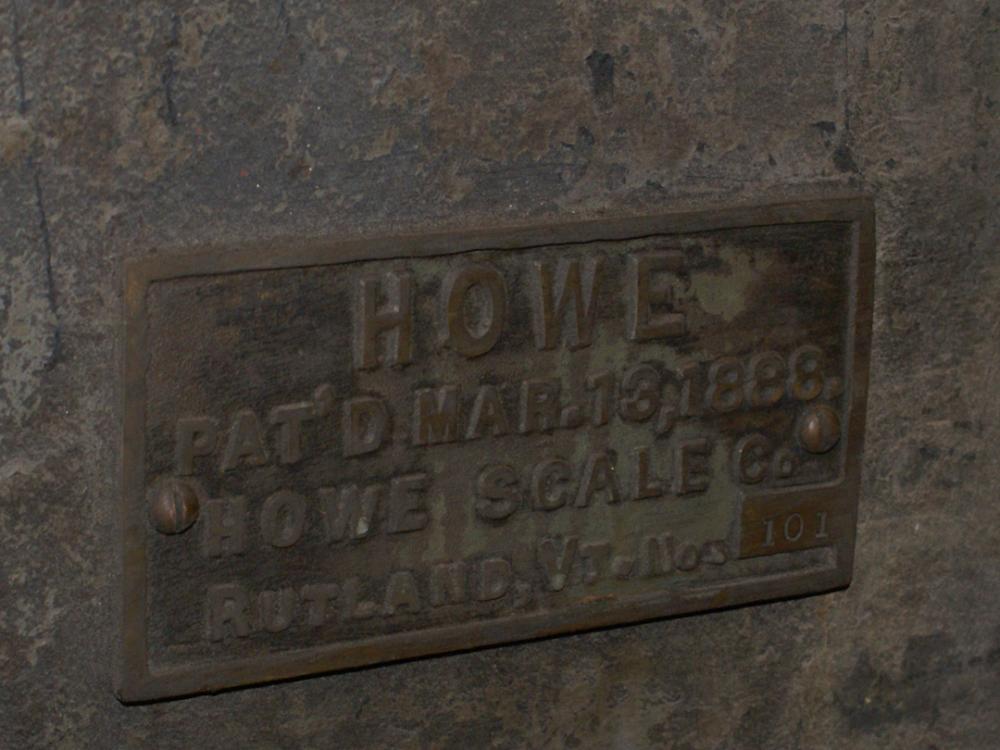

Those pages are from "Pounding out the Profits" c 1997 21 years is NOT an "Old Book" considering I consult one written in 1120 CE on a regular basis

With the exact date for the patent it should be pretty easy to find them. Of course the "in esse" version may differ some from the "in posse" one.

Several people have had new cushions made for their powerhammers if those need replacing you can probably dig out on IFI the info on where they went. (I'm assuming I can see a couple of doughnut cushions on it)

What is IFI ?? If there is a link on where I can buy or get cushions made please send that over.

-

-

not yet

Tried the numbers 379340 and nothing came up. I might be doing something wrong when searching those numbers

-

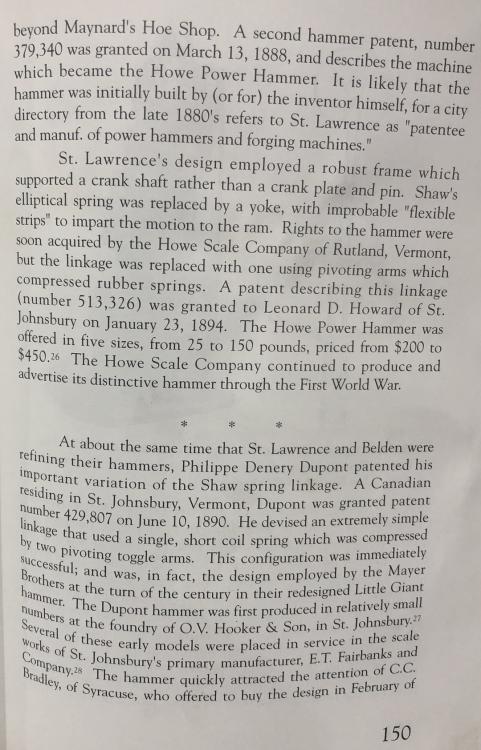

Last week I brought home a 200 lb Howe blacksmith power hammer. This is a beast of a hammer weighing in at over 5800 lbs. I bought this over 1 year ago and finally had sometime to pick it up. It is all there but needs a few parts rebuilt. What I am needing, asking, and searching from fellow metalsmiths are publications, advertising, pictures, articles, ect, or anyone in the US who might have one of these who would be willing to share some incite and info on these. I will begin rebuilding the few parts needed to get this up and running. Andrew Alexander from Austin sent me 2 pages from an old book with a few words about the manufacturer. Any help will be gratefully appreciated.

Thank You

Paul Ivazes

8 1/4" Columbian Leg Vise with rare base

in Vises

Posted

Ah ha. Did not know about that part. Looks like something I can make easily. Thanks for sharing