-

Posts

143 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by tinkertim

-

-

-

What's even more interesting is that they are bringing out metal-loaded filament for these 3D printers.

This lets you print a prototype that is 80%~90% metal content, and then you can Sinter it in a furnace (Forge?!) to burn off the plastic binder and leave behind a solid metal part ready for use.

You have to allow for a shrinkage factor as the plastic binder is burnt off, but you can put that factor into your Slicer program and it will scale your design appropriately.

They have Brass, Copper, Iron, Ali and varieties of Stainless. They are still pretty expensive as they are new, but once you have more suppliers in the market, the costs will drop. If you want to make a one-off it makes sense, if you want to make a few then the lost-wax(plastic) method makes more sense.

Google: markforged

Google: thevirtualfoundry

Can't wait as this gets more mainstream!

Tink!

-

Hi Dan (D.Rotblatt),

Had some issues with my Colloidal Silica slurry / Zircopax mix.

I had tried to mix it 50:50 by volume, but made the mistake of adding Zircopax to a fixed volume of Silica slurry, to try and double the volume of liquid.

This gave me a mix with much more Zircopax in than I expected. It coated pretty well for the 1st coat of the Ceramic blanket and the IFB floor as it was so thick.

The downside was when I came to re-use the rest of the Zircopax Colloidal Silica mix for the next coat, was that the majority of the Zircopax had set solid in the bottom of the jar! So I've probably wasted ~1/3 of my Zircopax!

Ho-Hum, at least there was plenty that would come up in suspension, so I could recoat the inside of the Forge and the top of my IFB raised-floor inside the Forge.

I think next time I will measure out a dry volume of the Zircopax to match the wet volume of Colloidal Silica slurry. Its all about learning!

Here are some pics of progress.

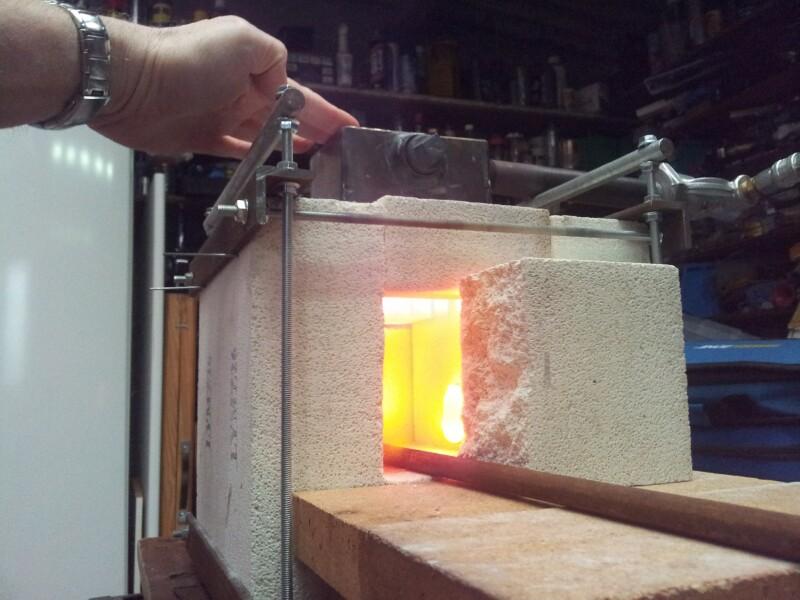

My new Forge with a raised floor made out of IFBs, coated in Zircopax / Silica slurry.

Firing up the NARB to finish the curing of the Zircopax / Silica slurry coating.

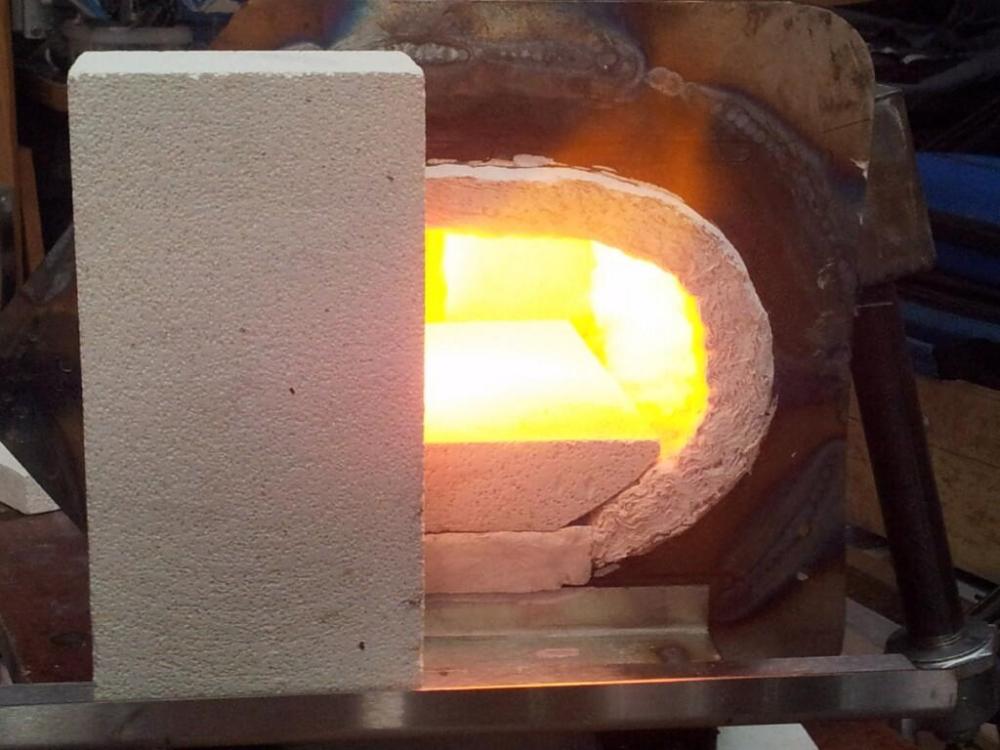

Ramping up the gas for initial testing.The raised flooring worked really well and with the whole inner lining glowing bright yellow, the centre of the raised floor was running just slightly hotter than the rest, and you could see particles that I assume are Zirconium Silicate just glowing a little brighter. The flame also circulated really well and gave a really even heat everywhere else.

Overall I'm very pleased with the results of using the Zircopax / Colloidal Silica (ZCS) mix to coat the inside of the Forge. It is hard, but as it's not very thick I would expect it to crack a little if bashed by accident, but as you said, just patch up with a couple of coats of ZCS where the crack is and all will be well again.

I also found that with the raised floor, I had to adjust the jetting of the AMAL propane injector and the 110 sized jet was giving me too much Dragon's Breath (DB) when I turned the gas up. Going to the default 90 sized jet gave me a more neutral flame with only a little DB.

The most useful thing is how little gas pressure I need to get the Forge up to hammering-steel temperature. The inside all radiates at the same level and the heat is really even. It might not be so useful if you need a hot-spot, but I can accept that if it runs more efficiently.

Thanks for all the suggestions and support Dan. I'm a convert to your forge lining technique!

Tink!

ps. I've dug out an old digital camera with a decent zoom, so I'm going to see how well it captures high-heat pictures.

-

Good progress Ig,

I'll keep watching.

Tink!

-

DIY forge / NARB update.

Initial Forge Shell 1

Initial Forge Shell 2

Spraying rigidiser 1

Spraying rigidiser 2

Second layer rigidised

Initial NARB lit to cure Colloidial Silica slurry / Zircopax Hotface.

Curing Hotface 2

Curing Hotface 3

Curing Hotface 4

Dan's (@D.Rotblatts) Colloidial Silica slurry / Zircopax mix seems to work very well as the Hotface coating.I've probably mixed too thick a solution of the coating initially, but the Ceramic Wool, the NARB flame face and the Insulating Fire Brick (IFB) took the Hotface

coating well, in fact the IFB & NARB have a near-glazed appearance.I will be adding some extra layers with some glass bubbles in it at the weekend, as well as a few tweaks to prevent flame leaks around the ends of the IFB.

I will also be making a raised floor to reduce the working volume for smaller jobs.

Very pleased with it so far.

Tink!

-

Hi Bart,

Sounds useful stuff, but as a hobbyist I cannot justify the ~£240 for a 25KG bag delivered to the UK.

I'll continue on with Dan Rotblatt's Silica investment slurry + Zircopax technique.

Although it might not be as strong as Kast-o-Lite, but with a lower thermal mass & IR re-emissive Zircopax, it should make for a quicker & cheaper forge heat-up for a hobbyist's use.

Tink!

-

Hi Dan,

Bits have arrived and I've been busy, and I have the Forge lined with 2 x 1" Ceramic blanket and have rigidised both layers successfully.

So now comes the Heat-face layer.

I have the Morisol-X30 Silica base, Zircopax flour and glass bubbles. I know you suggested adding the Zircopax until you get the consistency of Latex paint, but I wondered if you had any insight about how much glass bubbles to add, to get a suitable mix to apply.

Any suggestions regarding ratios?

Nearly there.

Cheers,

Tink!

-

A British Bulldog!!!

NARB!, NARB!, NARB!

(and I do have a head-cold at the moment!

)

)

Tink!

-

I've had good results with my drilled K26 IFB NARB (Buzzwords!!!). The new forge I'm building for it will be faced with D.Rotblatts Collidial Silica Investment slurry, mixed with Zircopax. I'm going to use this to treat the flame-face of my driled IFB NARB, to see how it hold up to the heat, long-term.

I'll post up results.

Tink!

-

You mean something like this?

Tink!

-

cool! Thanks Dan,

I was a bit worried I didn't have the right stuff.

Just waiting on the Zircopx to arrive and I'm good to go.

Cheers,

Tink!

-

Hi Dan,

A question for you. What does your Colloidal Silica liquid/slurry look like?

I've got some of the Morisol X30, and it looks like a cloudy, translucent liquid. It seems quite watery, but you can feel the Silica if you dip a finger in and rub it with your thumb.

I guess I was expecting something grey and opaque. Is that what your Colloidal Silica liquid looks like?

Catch you later,

Tink!

-

I've got a mask spec'ed for heavy-metal vapour, and I might just burn the relevant areas off with the torch outside in the garden. I know the dangers of heavy-metal poisoning when you heat or weld anything galvanised, hence the breathing mask I wear under my face mask when welding any. I've done a fair bit in the past, and always used a breathing mask rated for metal-vapour.

It's just the size of this bucket gets me the forge volume I was after, with a little extra width when needed for curved/bent forgings.

Tink!

-

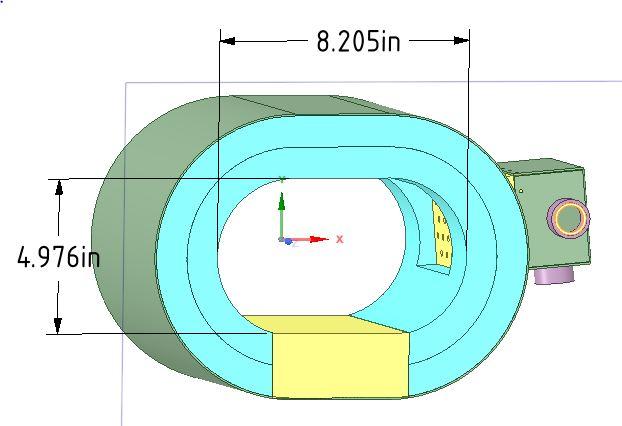

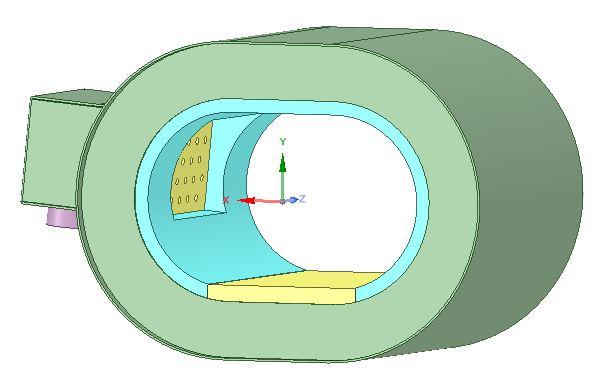

Well I've been hunting for a suitable container to build a new forge within, to suit my IFB-based NARB. Having seen commercial oval forges for sale, as well as reading about people using an exhaust "muffler" (or silencer in the UK), I had an idea.

You can get oval steel mop buckets from a company called Screwfix (Google: screwfix steel mop bucket) as well as lots of other places on the web. They offer dimensions for these buckets, but it's not clear where the measurements are taken from, but from my initial guestimations it should come under my 350 cubic inch target, so I went and bought one.

I then measured it accurately and mocked up a CAD layout for a two-layer of 1" ceramic fibre, with an Insulated Fire Brick (IFB) as the base, and cut a hole in it where I think the NARB would suit.

The depth of the bucket is 8.5", and with the dimensions I calculated, the inner volume to be ~324 cubic inches! Right where I wanted to be with a 3/4" AMAL Propane injector feeding the NARB.

I'm hoping with the longer roof (due to the oval shape) that there should be a good amount of roof and wall to radiate IR downwards, and the oval shape should allow for swirl as well. I will be making up support brackets at the front and back to allow for IFBs to be positioned to reduce the opening size, and I will be grinding off the galvanised finish on the edges of the bucket where flames might reach, and will coating the inner, and outer edges with the Colloidal Silica slurry and Zircopax mix in D.Rotblatt's fashion.

Any feedback on the orientation of the NARB burner?

Tink!

-

I thought the Silica micro bubbles wouldn't melt as long as they were not on the flame face.

I guess either silica micro-spheres or voids where micro-spheres used to be are both going to have pretty much the same effect; they make an insulating refractory.

I just need time and bits to play with.

Tink!

-

Cool!

Thanks Lou, I'll look into that.

Tink!

-

Thanks for the suggestions Frosty, I'll do some local hunting.

Tink!

-

Interesting! I bought a small bag of Perlite in a garden center last weekend, to use as an insulating bed for slow-cooling of blades, annealing, etc.

Would it be up to welding temperatures if mixed with a high alumina refractory?

-

Hi Mikey,

I had come to the same conclusion. I have seen sites selling many of the individual constituents, and I believe its the glass micro bubbles that make the refractory an insulating refractory. If I can find places that will sell small amounts to experiment with, then I'll have a play.

I'll post up my findings, as and when.

Tink!

-

When they talk about a colloidal silica slurry, I believe it contains more that just Silica & water, as it also frequently mentions "binder" in various slurry descriptions.

I think what confused me originally is where various products refer to colloidal silica, but some are referring to a pure dry powder and others are referring to a suspension of colloidal silica (potentially with other chemicals/minerals also included in it). They are definitely not the same thing.

When I place an order and start my build I'll take loads of piccys for reference purposes. It probably wont be for a few weeks though.

Thanks for the help Dan, I'll keep you posted.

Tink!

-

Hi Dan,

I like it when someone gathers experimental evidence, with for & against examples, and gives reasoned analysis and logical conclusions. It ticks all my nerdy engineer boxes!

It's quite difficult to find companies who will sell smaller amounts of materials and stock in or ship to the UK. (Kastolite-30 being my biggest headache!).

Here are the [Google searches I used to find] the materials I can get shipped in the UK that I'm going to experiment with:

GOOGLE: mbfg fumed silica

GOOGLE: scarva en gb zircopax

GOOGLE: ulster ceramics morisol x30

It's not clear whether the Morisol-x30 is in powder form or a ready-to-use liquid, but as it does come in 1Litre, 5Litre, etc. I think it should be liquid.

Catch you later,

Tink!

-

Hi Dan,

It sounds like you've done some really useful comparative tests, and following your reasoning & observations, I agree with your conclusions.

I've found somewhere I can buy small amounts of colloidal silica slurry, as well as Zircopax and the fumed silica powder, so I'm going to get some of each. As you and others have done, I'm going to use the fumed silica powder & water for the rigidising, and then use the slilca slurry & Zircopax as the hardened hotface.

Thanks for clearing up my confusion with the different types of Silica products. I feel I can source the right kinds of materials now.

I'll keep you posted when I start my new small Butane tank forge build (once I can find where I put the empty tank!)

Cheers,

Tink!

-

This is the thing that was confusing me a little, as numbers of people appear to be using "Fumed Silica" powder mixed with water as a rigidizer on their ceramic blanket, and heat it up to set it, before laying on their insulating refractory coat.

Dan, are you saying that when you have tried this it ate your ceramic blanket, or only when you mixed Zircon flour and colloidal silica powder, added water and then coated your blanket it ate the blanket?

Hmmm.

Tink!

-

Hi Dan,

I can get some Zircopax (Zirconium Silicate powder) in the UK, and I've found Colloidal Silica as powder for adding to Epoxies as a thickener.

It's not clear from your reply how much or what ratio I might mix these two, before mixing up a slurry with water.

Also it sounds like you are accelerating the hardening of each coating with heat. Is this just putting the propane on low for a couple of minutes every 15mins or so, or do you have a different method?

I'm happy to take my time and have a play, but don't want to ruin my ceramic blanket before I get to use it in anger.

Tink!

Flared Ribbon Burner Ports?

in Ribbon Burners

Posted

Hi David,

My burner is a drilled-IFB NARB, so no blower.

I am using an AMAL 3/4" Propane injector, which is a very efficient Fuel/Air mixer and is very adjustable, so I do get a nice hot flame, and a very even heat.

Tink!