-

Posts

2,551 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by BillyBones

-

-

That is how about all my tings are done. Heck i do not even usually forge weld, just break out the little stick welder and i am done. They are ugly but they work. I did recently make a couple sets of small light duty tongs but they were made from 3/8" (10mm) round bar so no drawing out.

-

We are divided into groups, set-up guys and operators. Those of us who do the set ups are the ones who have to have a good grasp on machining and even metallurgy.

One day about 2 weeks ago i came in and we had a quick meeting. The old guy in the tool room gave us a good but chewing becuase someone ground aluminum on our big snag grinder and clogged the wheel up. it is a 14" grinder so those wheels are far from cheap.

-

I ran a red light. Stopped, looked both directions and went. The tester looked over at me slowly and said "You realize you just failed?"

I love Dwight Yoakum and that is maybe my favorite song by him.

Or this one

-

I could have absolutely hit some one when i walked into work today. If any have been following my reamer saga it did not end.

Thursday i switched from a reamer that would not hold the dimension to a drill and ran half a shift of good parts. These ... "guys" on day shfit came in today and spent 7 hours trying to get the reamer to work. Oh and there is no reason to have a reamer other than an Acme screw machine could not make the parts with a drill with out throwing a big bur out of the hole. There is no finish requirement. The whole part is only .080" thick/long. It is molded into a piece of plastic to keep a nut from smooshing the plastic when attached to a stud and tightened down. As long as that hole is no bigger or smaller than waht the customer, Honda, wants, it is a good part.

Sorry, i just had to vent some. Just got home and have been mad enough to spit nails today.

-

These little 110 welders have actually been on the market for a while. They have gotten smaller though. My wife bought me a Forney easy weld about 5 years ago. It is a bit bigger but smaller than the cheap wire feed they sell at harbor freight. No i will not be welding sky scrapers or battle ships with it but for use in tacking billets together, and other light duty welding i would highly suggest one. When she bought it the cost was ~$150 - $175.

I have not watched it yet but i believe that is the same welder that John Switzer, Black Bear Forge, did a review on a couple weeks ago. The $80 dollar temu one not the Forney.

-

Our CNC department is lucky if one of their machines makes in a day the volume i can make in an hour. They do however make a Davenport that is CNC now, we do not have any, that i beleive can produce that volume.

I f find them quite amazing machines. Everything works off cams and gears. They were designed at the turn of the century originally to run off a belt drive system.

-

I once heard this, in Appalachia that thing on the hill is a tyre, as in "that radio tyre up yonner". So woundnt that make that thing you mow your grass with a "pyre myre"?

My wife was watching a show once about hillbillies. They had this guy on there they were talking to and they used subtitles when he spoke, i understood every word. I always like to say i speak 2 languages, English and Hillspeak.

-

I do not know if you know anything about screw machines but these are made to run high volume parts and are not CNC. One machine that i run in a 10 hour shift makes 17,000+ parts. I can hold tolerances of +/- .001", usually, doing that as well. So heat is a huge factor in what i do. Heat and chips are my 2 biggest enemies.

-

"We got both kinds here, country and western." - "The Blues Brothers"

I read once that in the southern states that prior to the Civil War there was not much of a southern drawl. People spoke proper English. Not to be confused with the hillbilly twang as i like to call it, that you hear throughout the Appalachians. Which id where the Scotts-Irish settled when coming here. There are also a lot more Gaelic and middle English words that are still used today through that area as well. For example it was pretty common to hear some one refer to a sack or bag as a poke, as in the expression " a pig in the poke", when i was growing up. Which is also why people from that region of the country know where yonder is as well.

-

I went to a hammer in a couple months back and one of the smiths there was using a hot cut similar to this. A 3/8" x 3" x 2 3/4" piece of A-2. I used A-2 becuase that was the only piece of steel i could find at work the fit my needs. As we all know hot cut do not HAVE to be high carbon. Wish i would have taken the 4" wide piece after making this though.

I figure for a beginner or novice that does not have the skills yet or maybe just not the tooling to move large material to make a hot cut this idea could come in handy. No forging all just stock removal. Entirely made with a 4" angle grinder.

Yes my anvil has a few dings ad chisel marks but it is a Mousehole that is 150 years old though.

-

Fun little fact, scat singing originated from Celtic music. This song has a bit with the wok fo lad dee ra part.

I am a huge fan of Celtic/Irish music. Speaking of which Shane MacGowen singer from the Pogues passed away this past week.

-

The temp was at most 100F. The reamer is in a floating holder. I am also not the one who tooled up the job and have no clue as to why they chose a reamer. I ended up using a 9mm drill (.3543") ground down slightly to about .354" in a rigid holder and cut 1000+ parts after lunch.

This job is on a Davenport 5 spindle screw machine. Notoriously difficult to get reamers to cut worth a ...

-

I have lived in many places in my life but none long enough to become a local except for where i live now. I spent my formidable years here, moved away to other places, and then came back.

I remember me and my freinds always saying that first chance we got we were leaving this place, and we all did. With just a couple exceptions we all also moved back and stayed.

Since we are talking about relocating a bit of relocating music

-

You ever see something so obvious but it takes you years to realize it? I just had that moment. Of all the years that i have worked with metal from blacksmithing to machining i just now put the 2 and 2 together that tenoning dies are closed die. Doh... I just always thought of closed die as something on an industrial scale with huge presses and the like.

Frosty, now that i see it as closed die you are absolutely correct, you have to have that relief.

I use my monkey tool as a gauge, once it fits inside that i am pretty good to go.

Mentioning holes and a bit off subject, i spent 6 hours today trying to get a reamer to cut within tolerance. I got .3535"-.3565" And with a .3545" reamer it would cut both undersize and over sized. Using an 11/32" drill (~.344") as a pilot. Bout pulled my hair out.

-

My guess would be 2 pieces.

-

Thank you, we really need a blush emoji thing.

-

Same here as well. If you are ever near Dayton, or just want to make a road trip, and want to mash some metal give me a holler. I aint no teacher but have learned a few tricks in my time.

May also want to look into ABANA and their online classes.

-

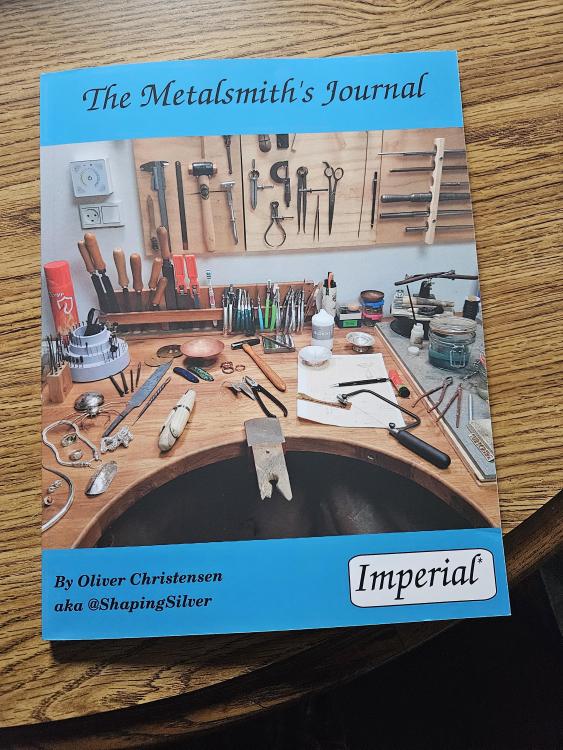

Frosty, i saw Tjorborn Ahmen using one in his latest video. He did make a pendent though in that video so still jewelry. That made me look into it. Even though it is not specifically geared toward the blacksmith for $8 i find it worth the investment myself.

-

I had to look up Bloomdale, lived in Ohio most my life and that is a new one to me.

Have you tried NW Ohio blacksmiths?

-

Frosty, it was about $8. Off amazon.

I really, really do not like to use that website but sometimes you just have to.

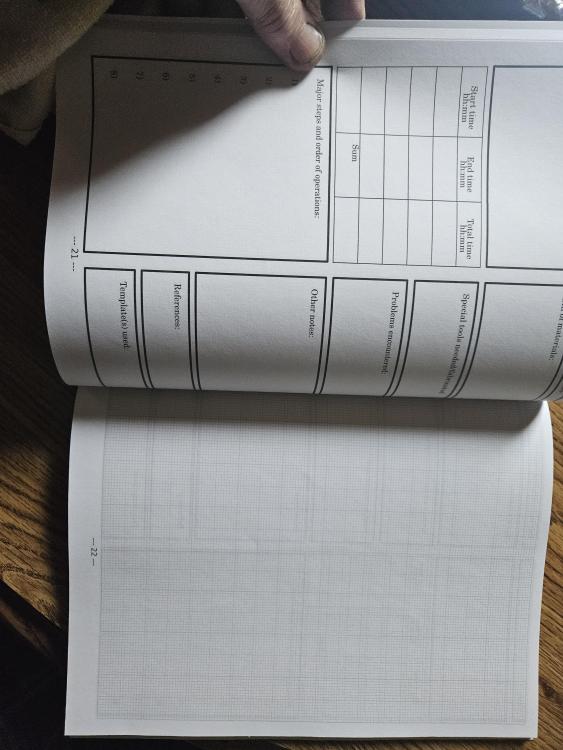

There is also a table of contents that you fill out so you know what is on each page. As well tap and die charts. I am also pretty sure it is geared towards jewelry makers cuase there is also a conversion chart for ring sizes from country to country and a AWG chart.

-

-

MacLeod, I have been trying to figure out how to make them out of pipe so that i can run wire through them to get an electric light. I do not want to weld them or I want to have at least the appearance of traditional joinery. I tried an LED solar light, it was nice for about a month then it just kind of piddled out.

I got that same dark problem but it is the front of my house. When i bought the house i did not notice that it did not have a single outside light. So first thing i did was hang a nice HPS lamp outside my shop. Lights the backyard up nicely but the front is still dark. We use the back as the main entrance though so for me it is no big deal. The wife however likes to walk to work a lot and she does not get home till after dark and wants something to light up the front of the house.

-

Thanks Das. There comes a time when you just have to stop rather than do more damage. I have been off work since Wed. and have put in a good 35 hours in the shop, so it has been a good weekend.

I also forgot till you posted, but i love that bearing snowman.

-

Is that box store steel?

The reason i ask is that what i have gotten from the box store lately seems much more prone to cracking like that.

I am assuming that box store steel is A36 and i am comparing to the A36 i have gotten from my supplier.

Simple guillotine

in Tools, general discussion

Posted

And the saga continues.

They decided to use the reamer like i said the other day. What i left out was that they had also decided to mess with the spindle bearings. When i left work Monday one of the spindles had quit feeding, the collet was not opening. I left out the other day that while trying to get the reamer to work the guy on 1st shift decided that it must be that the spindle bearings was loose, so he tightened them. So the bearing locked up. Yesterday i walked into the machine half tore apart. I pulled all 5 bearings, installed new. The press in bearing were now to tight for the spindle so they needed honed. Rather than getting a hone that can be used in the machine, think engine hone, first shift guy and the foreman decide to pull the bearing back out, press in remember, and put them on the lathe. Use a piece of sand paper and a finger to remove a couple thousandths to get the spindle to fit. Why? Becuase they were not sure if an engine hone would be concentric enough.

I threw up my hands and said i was done. They can fix it.