-

Posts

16 -

Joined

-

Last visited

Profile Information

-

Location

Bozeman, MT

-

Interests

Metal Fab, Auto restoration, Woodworking, Electronics, Internet of Things, Old Cars, Antique Tools, American Pocket Watches, Blacksmithing

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

What did you do in the shop today?

MT Hammer replied to Mark Ling's topic in Blacksmithing, General Discussion

Total newbie here... Up to this point I've been consumed building a gas forge, burners, etc, then getting an anvil stand fabbed up. I had yet to actually heat and beat any metal! Today I finally produced my very first smithy project--these flat tongs. Now, most of you can see they're not terribly refined, but I couldn't be more chuffed. I hope to refine my skills as I make more and more things in the future. Seeing all the amazing works on this forum is very motivating. -

Show me your anvil stands

MT Hammer replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

I've read this thread a couple times, and saved off images of the stands I liked. Thanks to all who posted their builds, I never could have made mine without ya. I think I read the 15 degree suggestion from someone else as well. I based my design around that angle, both the angle and splay of the back legs, as well as the front leg. I then did bed it with silicone, which definitely deadened the ring on my anvil. -

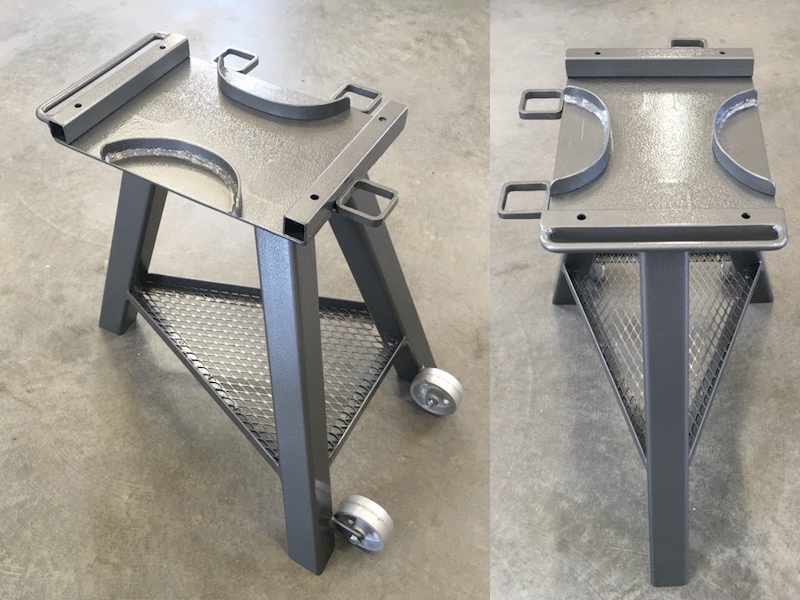

Custom stand for an Emerson 150 lbr.

MT Hammer replied to EricB1403's topic in Stands for Anvils, Swage Blocks, etc

Very nice design — clean and functional. Quality welds and attention to detail are very apparent. I like the theme that this and the other sample you posted have in common. I will shamelessly use some of your ideas in building my own stand. Thank you! -

IFB: Are some manufacturers better than others?

MT Hammer replied to MT Hammer's topic in Insulation and Refractories

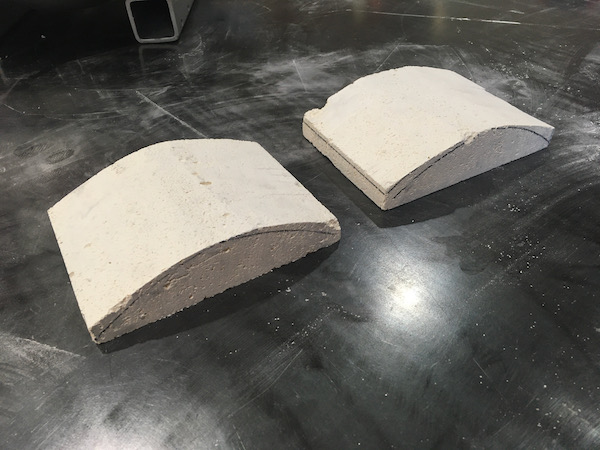

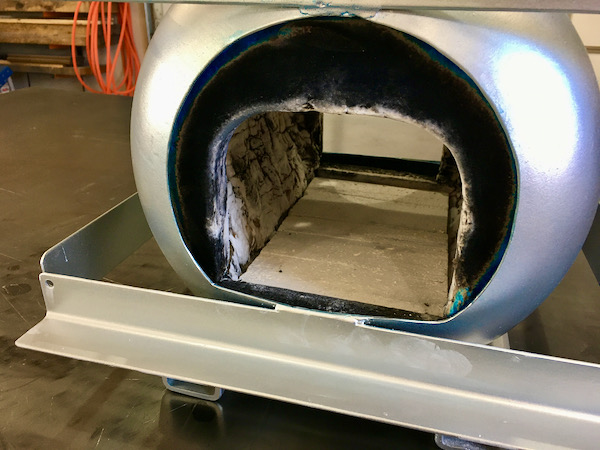

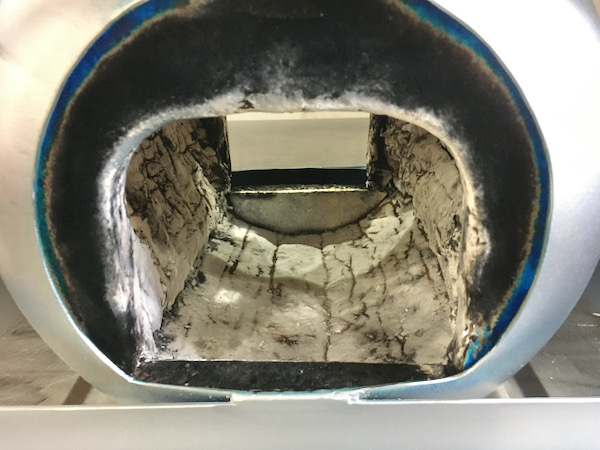

I was building a typical propane bottle forge, starting with kaowool. However, one of my applications for the IFBs was to provide a more stable "subfloor". I shaped the bricks to match the radius like so: These then neatly fit into the bottom: With that said, I can now address your question a bit better. As I understand things, Kast-O-Lite 30 is a castable refractory, while Plistix is a kiln wash. The Plistix would probably add a little strength to your soft brick, and certainly re-radiate IR, but will not add the strength of Kast-O-Lite. What I did was to then add a layer of Kast-O-Lite over the soft brick: Later on of course, I also cast the walls and the roof. After the casting was cured, I then painted on Matrikote, which is similar to Plistix. In fact, in hindsight I probably should have used Plistix instead. Again though, Plistix is a kiln wash. I'll let others weigh in on whether or not it could add strength and durability to soft insulating brick. I certainly understand the health concerns of kaowool. However, if proper precautions are used during installation, and then it is rigidized and encased in Kast-O-Lite, then I think the possibility of releasing fibers is eliminated. Also, from what I've read, soft bricks alone on the floor would not be a good idea as they would not hold up well at all. I assume you were planning on using hard brick or a kiln shelf on the floor.- 11 replies

-

- ifb

- morgan thermal ceramics

-

(and 2 more)

Tagged with:

-

What we're getting from you is that you don't want to spend the time to do the research. But yet, you want the experts here to spend their time to tell you exactly, step-by-step, what to do and how to do it. I myself am just a beginner, so I can't help you. I've been in the same boat, trying to wade through the 64 pages of the Forges 101 thread, and the 96 pages of Burners 101. But you gotta do it, and you gotta put in the time. The impatience of looking for the quick and easy answer is what got you to this point. The best way out is to slow down, read through all the info presented here. All the answers are here, multiple times, over and over (which can be hard to get through). Have you read the Consolidated Notes For New Forge Builders? That's a concise read, and give a good overview. Then dive into the 101 threads.

-

Thanks to you esteemed gentlemen for the kind words. I'm sorry I did not present something more criticizable! Luckily, there's trouble in paradise... my kiln wash has cracked and spalled. That this is my fault is no doubt, but I don't know the reason. It could be that I applied it too thick, or maybe didn't cure/fire it properly. It air dried over a week before I applied any heat. I first warmed it some with a map gas torch. Then fired the forge to 1/3 heat, cooled, 2/3 heat, cooled, then orange hot. Now Ive got to fix this mess. I should probably post this question in the Insulation and Refractories section, but how dangerous is this? The MSDS for Matrikote freaks me out a little when it states, "After exposure to temperatures above 1600˚F, Cristobalite and Tridymite are formed." Yikes! But these horrible lung eaters are not aerosolized normally I would guess? Now when I try to scrape and clean this failed attempt, I am guessing I should be pretty careful? By as high, you mean as I want welding temps, it is not rated that high? Of course, the two reasons I applied the wash in the first place was to make it more efficient, and also to protect the floor from direct flame impingement and flux damage.

-

Thanks for the comments. I’ve at least managed to squeeze my way into the ballpark then, it seems The frame around the tank will be used to support some K26 bricks to be used as doors. I decided upon this route so it could be modular and also support front or back porches, etc. I hope the Matrikote serves well as a heat-reflector. I also coated the door bricks with that, both for IR reflectivity and also to strengthen them a bit.

-

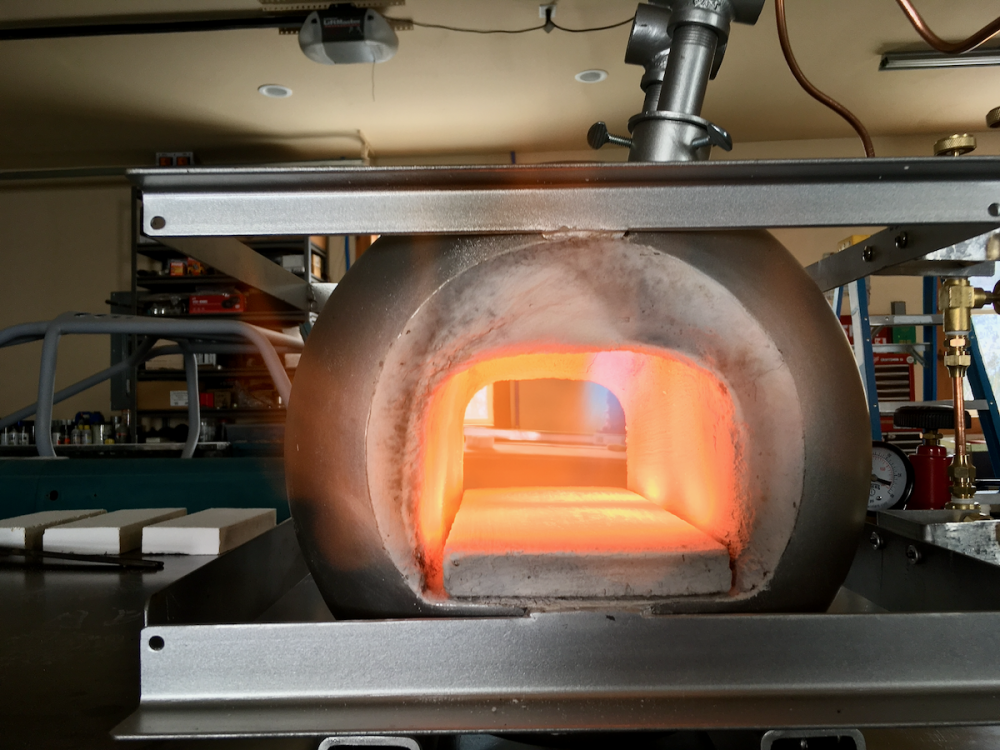

YAPBF (pronouced /yæp bʌf/ as Bloom County’s Bill the Cat would) I debated whether to pollute either the ‘101’ threads or the entire forum, but decided on the latter, not wishing to add to the 96 and 64 pages already in the threads. As one who has tried to scan/read/comprehend all those posts, I tnink my questions would not add value to the archive. In any case, here I have finally managed to complete my first forge build. My journey has taken me years (I have too many projects). While I know I’ve made mistakes, I’d like to know how serious they are, and what to do to mitigate them. When I started out, all I had was Michael’s book, so I started building the 5-gal bottle forge. Then when I found this site, I learned that I really wanted a smaller volume, so to make up for it I just added a xxxxxxxx of castable. I’ve got well over 1” thick in many cases. I painted Matrikote on the castable (although the directions say not to, but the concensus here is to do so). It seemed to go okay, but then felt fragile and powdery days after air drying. Heating seems to have improved to adhesion. I decided the Frosty T was the best burner for a novice like me. The burner flares are cast into the shell. The biggest problem a newbie like me has with the Frosty T is the need to tune them in the forge environment. Kinda chicken and egg deal when you’re building both at the same time and ya need the burner to cure the forge but the burner needs the forge to run. Hmm… I manged to get things cured and running reasonably well (I guess). From cold, it’ll get pretty orange hot in a couple minutes at 5 PSI. I’ve read all I can about reducing, neutral, and oxidizing flames, but I’m still pretty hazy as to what exactly to look for. Here’s the forge right on startup from cold: And here it is a couple minutes later: The dragon’s breath when it’s hot: I live at 5,800’ elevation, and am using .035 mig tips. They are trimmed about halfway if looking straight through the "T". Don’t know if I should try .030? The burners are probably too close together, but I’m not sure if they’re at a decent angle or not. This is running at 7.5 PSI: Any help, critique, or even laughter is certainly welcome!

-

Ya, I was going to ask the same question — I doubted I was the only one who couldn’t see any images. I see the placeholders, and filenames only. I’m using an iPad. Is that an issue, or is it a server problem with IFI?

-

Hmmm, I've obviously stuffed it up here. I bought some fumed silica (System Three 3105S16 on Amazon), mixed it as specified, and added some ag blue dye. Spritz the kaowool with water, and after letting that soak in a bit, proceeded to saturate it with the rigidizer. It looked like this (every probability I put in too much blue dye!) After it dried (took several days), I then attempted to cure it with the MAPP gas torch. The blue burned off as I got it all red hot, and that left it looking like this: The PROBLEM: It's not really rigid! It is a bit more rigid than it was before, but still kind of spongy. It's like a stale pound cake. As this is my first build, I'm not entirely sure how rigid it should be. I'm guessing though if I tried to apply the Kast-O-Lite over this, I'd have problems. Think I used the wrong fumed silica, mixed it wrong, used to much/little, or didn't utter the right incantation.

-

IFB: Are some manufacturers better than others?

MT Hammer replied to MT Hammer's topic in Insulation and Refractories

I ended up buying from an eBay seller. I realize that may sound risky, but this seller looked to be on the up and up. I just received the shipment yesterday, and it was exactly correct Morgan product. I ended up getting a carton of 3" thick, and I will resaw some of them to other thicknesses. Including shipping, these turned out to cost $7.50 each, which may not be cheap, but is less than I found anywhere else in small quantity. I can't speak highly enough of this seller. He actually refunded $10 to me when the actual shipping cost turned out to be less expensive than estimated. The bricks were still factory sealed in the MTC carton, and then surrounded by foam in another box. The shipment was very fast via FedEx. Wow. I know I am not supposed to directly link to a specific product or Web site here, but I'm not sure about naming an eBay seller. I would recommend this one, and feel free to PM me if you'd like the name. Sorry that I can't add any insight into the main purpose of my original question...- 11 replies

-

- ifb

- morgan thermal ceramics

-

(and 2 more)

Tagged with:

-

MT Hammer changed their profile photo

-

IFB: Are some manufacturers better than others?

MT Hammer replied to MT Hammer's topic in Insulation and Refractories

Ah, shoot, I just read my reply and was embarrassed by my 8-mile round trip. Wow a WHOLE 4 miles to town? Ah, how terrible. Actually, just a typo... it’s an 80-mile round trip. Yes, I do make the drive as required, but especially now with the Covid spike, I’m personally less comfortable spending a lot of time chatting with people I don’t know. It is nearly impossible to gain the insights online, and even difficult over the phone. In person is best I agree, but just not practical for me at this time. Other readers may feel differently. It may be that many retailers carry Morgan products and don’t even know it. It could also be that resellers would claim to sell Morgan products but substitute cheaper bricks, especially if purchased in less than carton quantity. Do the bricks themselves have any markings which would identify them as Morgan Thermal Ceramics K26?- 11 replies

-

- ifb

- morgan thermal ceramics

-

(and 2 more)

Tagged with:

-

IFB: Are some manufacturers better than others?

MT Hammer replied to MT Hammer's topic in Insulation and Refractories

I see a lot of 2600ºF-rated insulating fire brick carried by many sources, but few specify Morgan. What I was really after was some experience or advice regarding other manufacturers, and if one 2600 brick is basically as good as another. I did finally this comment regarding K-26 and specifying Morgan Thermal Ceramics on page 37 of the Forges 101 thread. That seems to suggest that perhaps not all K26 IFBs are created equal. And yes, for the record, in my small town, when I call around and ask for Insulating Fire Brick, I find that they either don't know the manufacturer, or they tell me that the bricks are all the same. I tend to trust the experience found here a bit more. I also live an 8-mile round trip from civilization, so I get most everything delivered -- this does have its downsides at times.- 11 replies

-

- ifb

- morgan thermal ceramics

-

(and 2 more)

Tagged with:

-

Hi all, I am building my first forge and burners, and have been reading this forum for months. In fact my brain is so full of information, that I have seriously began forgetting a good deal of what I’ve read here! i’m building a propane shell forge, with 2 tee burners (and here I’ll add my great thanks to Frosty, along with the many others), and I am planning to simply use bricks for front and back doors. Seems like 2600 degree is a good choice, but I’m not sure about a manufacturer. I’ve read Frosty and others suggest Morgan Thermal Ceramics k26. I have yet to find an online source for these, but see a lot of other 2600 IFB from other manufacturers. I plan to call around to see what I can buy locally. Before I do though, i’d like to understand if the relative quality is similar regardless of the manufacturer, for the same temperature rated IFB. Thanks!

- 11 replies

-

- ifb

- morgan thermal ceramics

-

(and 2 more)

Tagged with:

-

Thanks all. I thought I understood from all I had read that a main application was to be an IR reflective wash over refractory. So I was surprised by the directions. I feel I can safely ignore those and follow the advice given here. I’ll post some photos and results once I get the forge built and used a bit. Thanks!