-

Posts

53 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Teddybo

-

-

Yeah I use nasty cast rod made by Vulcan as a buttering later then 7018 and pre heat entire area to around 700 degrees because I find it helps burn up some impurities that has soaked in ( I’ve had oil like stuff a few times come ozzing out )and use temp sticks to verify . I always cleans the heck out of the area and and like ya said short welds with a needle scalper to fallow and don’t let the cast iron drop below 500 then when done depending on size I either put it in a large tub of carbon pellets I get from filters I use in my shop ( I get them for free from weeds growers and then hook up to a squirrel cage and they control odor and dust ) and if the item Is to large I wrap with a couple welding blankets then moving blankets

and Nd I just don’t like the way brazing looks and silver braze is not friendly with large gaps

-

Another scrap yard find - pays to make friends with workers . They set stuff aside for me -

i belive it’s been retrofitted - Handle doesn’t look stock

many advice would be helpful . I’m not worried about welding rhe old cast iron I’ve welded allot of nasty old cast iron and havnt had any cracked welded or purosity or failed welds yet .

i just don’t know what to do as far as making it function besides need a leather belt to drive the blower

-

Yeah the days of Companies standing behind their warrantees and not trying to void it or make you jump through hoops to register it are long gone

-

Lowes has craftsman now but that brand warranty is a joke . You have to register all tools bought online so any old craftsman you have pretty much has no warranty as well as their on line registration randomly will delete account . I Once tried to order a replacement part for a Sears air compressor that was a year ago after a month and a half of them giving me the go around I told him I was gonna call my credit card company and reported as fraud and they finally refunded me I’m still getting emails saying my order is back ordered

-

Ya I wish I knew who made it so I could call the customer service up and see if ifs to late to register the warranty

-

I understand what ya mean . I have repaired the edges that weren’t rounded so much as chunkes missing but was very worried about effecting the rebound pushing a heat zone or building up any heat over 420 degrees . Now I don’t ever plan to sell that anvil as it was my first and I wouldn’t blame someone for not trusting it was done right .I would never trust that repairs where done correctly by anyone who knew what they where-doing. I’ve seen countless videos and heard people boast about how they could do it or couldn’t be to difficult these people I watching people who thought they knew enough to repair it right only to ruin the anvil.. I knew I was clueless but didn’t realize how little I knew . . And I still don’t know didly squat

-

Well as you all have far more exp then me I’ll go with your advice on he edges . I thought it was wrought iron but when I went to clean it up it obviously had some kind of tool steel plate on top very thin no five eights more like quarter inch thick but still had some pea size pot holes in the face of the top plate .

just picked up this post vise up in Reeding there is a 5 1/2 inch Peter right post vise about another hour and half north in Klamath falls Oregon posted on Facebook was going to go try to grab it two but I never got reply back in week of trying to get in context .This one was supposed to be a 6 inch it up being a 5 1/2 it sure does look a lot uglier in person than was in the pictureI I don’t get all people when I send them an exact picture of what I am referring to is the measurement is still messed it up who’s going to pay 200 bucks good with the XXXXXX condition and wasted time to give her 80 bucks pretty sure it’s columbian . I made a good connection regardless the guy was showing me pictures of two different locations he knows where they have a bunch of anvils a and post vises as well as a friend of his that has a whole collection of them

-

Hello so my local Scrap yard is a frequent place I go to And one of the employees about months ago told me they had anvil at that time the owner was not willing to sell well yesterday I got this for 150 bucks I figured it be a lot better to get my hammer control down on this that it would be on my hay budden or Columbian’s and most will probably tell me a paid too much but locally I could resell around 300 once I fix the edges .

I’m pretty sure it’s all right iron it’s got about 80% rebound and weight originally was 177 currently and currently without the hill is 157 it has warranted and what looks like to you FTS them printed on it as well as JF i’ve tried doing some research and I can’t find anything on it

-

Are used to use linseed oil but it tends to leave a sticky residue behind and after one of the rags spontaneously combusted I have a stop using it I like the Johnsons wax because if you heat the metal a little bit it’s soaks in and it doesn’t leave a sticky feeling and leaves a nice clean look that I like and I also upgrade a lot I’ll sell two of them to go fund an anvil or a larger post vise or welding equipment . I’m gifted at buying welding tanks as well I like to buy them used full for 150 bucks and then I’ll sell them empty for $150 because I use up a lot of Oxygen acetylene each month and one month I actually had to pay for the gas was 600 bucks.I’m not in a for huge profit I like to make 50$ For my time and for cleaning it up as well as driving out to get these that are hours away usually

-

Bench vises I’m just lucky and got my most recent reed swivel jaw for free dude even delivered it from Sacramento to bay area. Prentiss one I got is scrap yard and ya the first Reed swivel jaw one I got for 60 bucks they weren’t nice looking when I got then I have to do akkotbid soaking ad heating to get the jaws loose and also both I had to repair the base on I’ve had to teach myself how to weld and repair cast iron and have gotten pretty good st it. I don’t use nickel rod you know I have a ton of it because it doesn’t color match and it’s riddle I tend to use a Vulcan nasty cast as a buttering layer and then afterwards use 7018 but first I heat the xxxx out of it to burn out any oil or anything else that might be in it and then I slow cool it Clean up the area I’m going to weld and then Head back up to around 400-500 f and weld it i’ve got to mention I also have a 6 inch Columbian bench Vise I got for I think 40 bucks Cause if didn’t have any of the jaw inserts I had a friend who has a YouTube channel “metal tips and tricks “and machine shop make me some jaw inserts and then I fix the screw nut and I filled in a couple pot Marks and am getting ready to sell it

-

I usually pay 100$ for 4-5” in great shape and tend not to buy littler ones they always need repairing

150$ 5 1/2”-5 3/4” lately

200-250 for 6- 6.5” and I only own 2x7” and paid 280 and 350 but the More expensive one the guy wouldn’t let me buy just a large one I had to buy a 4 inch and a large one

I use electrolysis and Johnson’s wax I found that if you use a wire wheel you risk erasing fine details that will help you identify certain post vises that Are not obviously one brand or another but I have two Indian vises that since I used electrolysis was able to see very very fine Indian chief stamp on the jaws in each . I’m kind a well-connected I responded to a lot adds even if they’re not showing blacksmith related items like if I see old tools I ask everyone . I connect more people that are buying and selling together also like guy I know was looking for 300+ anvil for good price and I knew someone 159 miles away who had let me jbjs he was selling one. And also I’m really nice when I sell items a lot of times if it’s father and son come over I end up giving them a ton of supplies for free I lost my dad about a year ago so whenever a son and father come over to buy something OK I hooked him up as best as I can shoot myself in the foot a lot of of the time doing it but im able to help them grow a bond and enjoy each others company . lotta older gentleman have an easier time relating to and talking to me because I’m very respectful and have values that are not seen nowadays with people my age -32

Are use Molly grease or other similar gear summer grease on screw and screw books and the bottom of the moving jaw. I buy the industrial giant 5 gallon purple power degreaser from Home Depot it is the best stuff I found yet xxxx takes up paint even .it’s pretty cheap for how much you get and i will soak/ fill the screw box with it and just soak it for a day and then when was washed out of water almost everything comes out

-

That’s not really that old that’s closer to their newest version of their bench vises maybe 30-40 years old

G man I agree on standard is jaw width not how far it opens . I’ve come close to chewing out someone when I drove 40 min to buy a vise not knowing anyone would think to measure other way but now know to be clear what measurement I’m referring to as it’s more common than I thought

-

172 hay budden carved out by hand a red wood block for a stand and have a 1/2” top plate bolted down with flat bar welded to some pipe that’s welders rk rhe plate so I have tong and hammer holders on bothbsides but now is to big and i want to change the stand but not bad first run That I fallowed the anvil mag write up on how to repair adds damage and repaired mine and fixed some top plate damage and am waiting to have a freind who has a mini machine shop and is going to use a surface grinder to give me the most accurate flat top plate but don’t want him taking more than a 1/32 off the original top plate and said he could clean up all the weld build up on the sides cause I was nervous to do it and mess it up cause it took 6 hours to fix and so far had bony lost any rebound what so ever but didn’t want to do it again I’d i didn’t have to . Also repaired 5 other anvils this way which paid for my 110 columbian and the 240$ in electrodes

120 columbian not mounted yet am going to build steel stand

110columbian needs stand

-

I’m actually currently dealing with a similar situation at the garage I rent and use as area to build things in . Except my neighbors are retired snobby xxxx couple who only leave the house to do garden work and frankly I didn’t even know their was more than 1 guy in the house I’ve still never seen the other guy . And without ever even saying a word to me let alone mentioning noise issue waited for me leave on my weekly trips to Sacramento to help my mom out , and proceeded to storm over and demand my landlord kick me out ,and my land lord was milliseconds from cussing them out his daughter interviened and tried to insure that what ever within reason could be done to not negatively effect them would be done but that I wasn’t getting kicked out and wasn’t going to be told I had to stop welding /metal work. They refused anything but me gone . Well they reported next that I was operating a welding shop as a welding business to the city and foolishly the daughter let the inspector on the property because the dumb inspector when she saw the garage inside tried telling me you Cant weld at home or use a garage in the manor I was - referencing all the steel I’d collected of a year from

scrap yards to use to make things FOR MYSELF. So anyways 6 months later and her issuing me a fine for not having a hot works permit I’ve talked to both county and city fire inspectors and she issued me the fine which only applies if you have a business and both fire inspectors agree with me it’s perfectly fine to as a hobby something ya don’t do every day .

Any ways I went on a rant their I have done a ton of research and some testing with decibel meter different approaches to keeping sound from escaping to be able to bother neighbors and hopefully ya can avoid the drama . What worked best for me is I built a grinding room in the opposite side of the garage and used 2 layers of 5/8” sheet rock make with overlapping seams and I helped a buddy tear down sound booths from a business and got to keep a bunch of preassmbled 8’tall 4’ wide walls full of rock wool and attached those walls On the inside of the room and then added a layer of 1/4” dry wall . Now I bought all the 5/8” sheet rock over a month of daily visits to home depot and finding damaged pieces and getting them marked down 80% or for free and the 1/4” I got for free off craigslist now the weak point to my room is the door so what I did after I got all large tools into the room was build a a wall in the shape of a L ok it’s side and at the end of the L have those hanging strips ya see in Commercial freezers ok it’s side so sound would have to bounce off a wall and through the flaps before even getting to the door which is the only thing I bough st full price and is a fire rated solid core that I hung with 1/16 or less gap around and has sound board /foam attached to it And the ceiling is just the double 5/8” rock

-

Ya have a very good point their ! I was recently educated on my ignorance to many uses for post vises. And your correct , and id add a true anvil with its great rebound helps reducing the amount you have to swing your hammer but even mild steel plate you would get same result to a degree , and rhe horn and a hardy whole can be made out of mild steel as well . So to date I have not seen or heard of any “post vise shaped objects “ So it stands a tool yet to be improved upon

-

MD

Just showing collection. As of right I have 14 post vises and a few anvils.

Today I am going to go pick up what I believe to be around 5 3:4” Peter Wright in Santa Cruz I have a lead on a 6 inch one in writing a 5 1/2 inch one in Turlock 34 inch ones for 65 bucks apiece in Nevada city actually Carson City and then a few more over in Sacramento if anyone was looking . Lately that’s been a hot spot thus will be the second blacksmith shop in the area in the last 30 days that I am lucky enough to get first dibs . Last one I spent every nickel I had and still only scratched the surface of what they had . I really enjoy digging though old shops not touched in 50-80 years .

anyways back on topic I currently have

7” iron city 150 lb screw pretty worn and leg chopped short not by me though

7” Indian 150 lb amazing condition

6 1/2” Columbian 130 lb needs new rivets as it’s come loose

6” Peter Wright 100 lb screw box has all writing legible and the crest jn the center - in amazing shape

6”iron city 100 lb - got at last shop in Lodi and is the first one I’ve ever seen without chamfers on the legs and the dual arm bench mount . Is this a newer version ? Doesn’t lok forge welded

6 “ unknown manufacturer 110 lb some wear in sweet spot of threads but I’m good shape still

6” Indian 100 lb in great condition and crest somewhat legible but suffered at had pitting on brace supporting arm

5 3/4” Peter Wright 90 lb In even better condition than the 6”

5 3/8 iron city 80 lb with chamfered legs in great condition but I need to reassemble it just got done going through electrolysis bath

5 1/4” iron city 70 lb with chamfered legs pretty Much unused in amazing condition

5” unknown manufacturer has 62 1/2 stamped on jaw and some lettering but no one has been able to identify it yet

5” newer drop forged columbian 35 lb only keeping cause it’s xxxx near perfect condition

4 1/2” iron city 45 lb just got this one man was the screw stuck on this one so bad I had the whole thing cherry red and the force needed to break lose cracked the screw so I had to weld it back - currently is electrolysis bath

4 1/2” frankin vise . Don’t know weather I should order some acme thread and a nut and make a screw and screw box or fabricate the oversized one it come with that’s obviously not not meant for it

4” Trenton 35 lb I traded a banch vise Thad was in mint condition for among trent

ones i've sold in last 6 months

5 3/4” columbian

P5 3/4” Trenton

4 1/2 “ columbian

41/2” iron city

5” columbian

4 1/2” arthor O’Leary

also so I have a 6” columbian bench vise I’m restoring model 506-2 and had new jaw inserts made for it - picked up for 50$

model 4041/2 swivel jaw and base reed vise only negative is the swivel base was cracked in half but I welded it back together

Actually just picked up another one of them the base is tore up actually it welded the top to the base but the rest of it seems pretty good and intact

I have a prentiss bench vice but I don’t know the model number and have had a hell of a time trying to clean up the cast-iron is so full of purities so I have to use an order nasty cast from Vulcan . But it has a pretty cool swivel locking mechanism Unlike anything I’ve seen does anybody have any insight

I also have a couple anvils

172 hay budden i fallowed anvil mag way of fixing the edges and am waiting for my buddy to have room in the shop to put it on the surface grinder and get everything nice and clean and done as far as the edges and table or let me know if I need to fill more

120 lb columbian

110 lb columbian

It’s amazing how 10 pounds softener and they ring it completely differently I must admit 110 pound one is annoying high pitch ring

I have all parts to post vises some are not done being cleaned up /restored

-

Iron city have the short chambered legs and extremely thick jaws and all have Avery distinctly well made springs . I wdtually copy their design when making. Springs for my other post vises both picture im confident are iron city’s . Iron city where one of 3 company’s I know of the did that type of bench mount but iron city are the distinct in their thickness and design

-

Looks like a iron city . Nice vise !

-

I may be getting a couple screws and screw boxes soon the post voices are badly damaged but I could repair them but it would not be as good as it should be so I figure part and out I’ll let you know if you want to sizes of the diameter of the thread and dimensions of the screw box in case you want to get on instead of making one .one of the Post vise is that will be dismantled id a 6 inche and the other was a 5 inch ones iron city and one I believe is an Arthur

I’ve had to do quite a few repairs a different post versus the worst was one had been previously attempted be repaired poorly and because the job had been knocked off all the way down almost to the base where the screw box is actually actually went in a little bit into screw boxes so there’s a lot of chamfering and a lot of rods and passes when I did was clamp the two jars together and put about a 3/32 shim the bottom so that way they were correctly angled and just kept welding it was a think a 4 1/2 Iron city after all things said and done you couldn’t even tell and it was perfectly lined up I just took a lot of work inside the hole the screw box goes in a lot of time spent with the carbide bur cleaning out the area I. They go so that one for 125 bucks but I let the guy know what happened and what repairs have been done

-

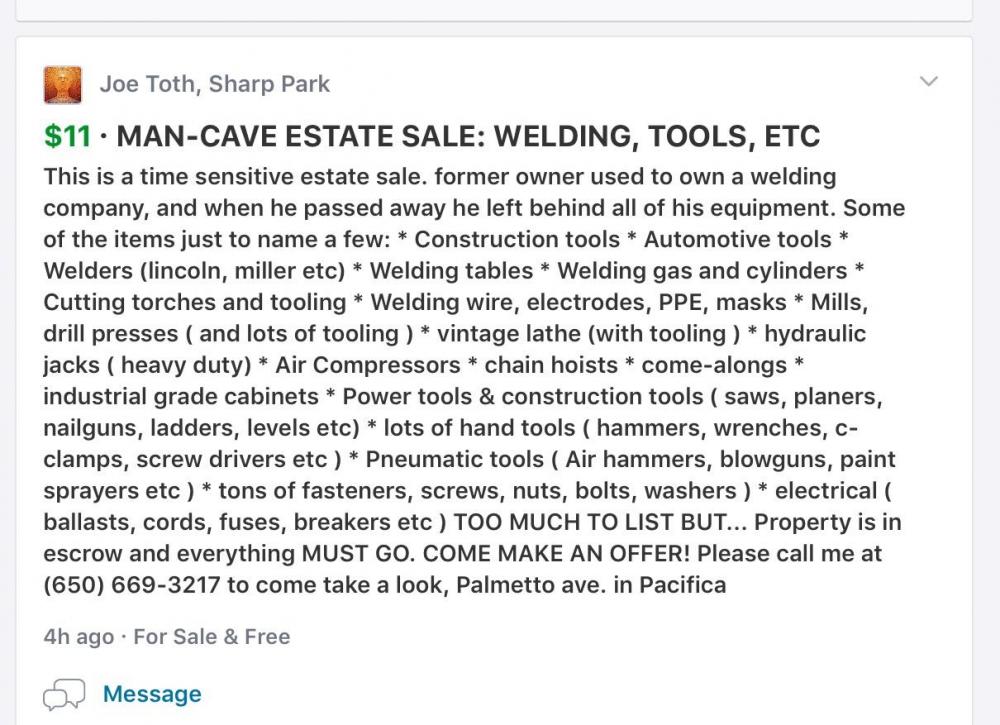

Exactly I’ve heard from another person that that flat chain is easy to find at farm supply stores I think I’m gonna go over the guy around 215 and see what he says I just don’t want to insult them and push them away I just thought that the Fisher double screws were really rare as their unique and the only one that works that way I’d love to get a foot visr as well. And since tomorrow I’m going to Statesville gentleman who used to own a welding business and I were had to sneak peek and the pricing is ridiculously low probably going to dump everything I got into it Because I plan to sell at least half of it there’s a really cool old stuff in there. Alive and have service roast but I don’t mind that I got time I’d rather clean some surface rust off for two dollars in buying it nice looking for 20 . Hopefully come out with 10 or 15 cylinders hopefully the two acorn tables and 40 other things on my list so the wife’s not exactly going to be happy when the garage is already stuffed to the gills now is Going to be over flowing

-

So I i’m going to a welding business estate sale tomorrow and I already had the opportunity to get a sneak peek at and bought 150 pounds worth of electrodes still sealed 20 bucks. The guys asking 500 apiece for the flat welding tables but I figure it out from 700 for both and by the way he was pricing everything else that I wanted pretty sure he’ll go for it. I don’t own a truck but I have friends who do and are willing to help me but the table isnt going to fit in the truck and I’m not even sure if trailers are 5 feet wide that I can rent .and I don’t know how to move it short of jacking it up putting thr legs on I-beams and then tackling them to the ibeamd and then slowly ratcheting it over pipestone roll oh onto a trailer does anyone else have a better idea

-

I Learn something new every day. Thanks

-

I don’t know whya blade Smith needs a vise built for take a beating and not being phased by it . But then again I’m not a Blake Smith Or wouldn’t even call myself a blacksmith . I’ve only been interested in post places for six months now as well as anvils and blacksmithing .and you’re right there’s probably more anvil and post vises remaining in fabrication shops wood shops then on farms . But with San Francisco and surrounding areas huge numbers and such a small area it makes it so the few that are available either are spoken for or go for top dollar I’m not willing to pay that much.but 3/4 of the 20+ post vises I’ve bought came from farms either I bought it directly from the farmer or from someone else who did . And yes back in a days people were more into repairing things than throwing away , they also were very patriotic in though I don’t have any evidence to show that huge numbers of anvils were scrapped only going off what I was told but you gotta figure Americans are very patriotic back then enough to handover hard earned money to the government right after a depression with an IOU in exchange from the government in form of a war bond and if moma is donating her pots and pans you think she’s going to not donate an anvil not being used much if at all

-

The gentleman actually had a post on craigslist for a 5 1/4 inch post vise and I sent him an email letting them know he was asking about $100 more than I thought he would probably get for it politely and he responded back thanking me and actually did drop the price by 75 then sent me another email asking me how much the double screw post vise was worth I told him I’ve seen them on eBay for two grand but it’s been up there for a while and told him I’d be interested in Purchasing it but not at that price So he said he would be interested in taking a offer but I don’t know what they go for in real life go for not eBay

Help identifying scrap yard find anvil

in Anvils, Swage Blocks, and Mandrels

Posted

Boy did this post go off topic