Brian Evans

-

Posts

75 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Brian Evans

-

-

Not completely, I use small pieces of coke and anthracite to refill the fire pot. However the fire cave lining still burns just not as quickly. I will take pictures of it before I fire it up to help explain it better. I know I'm not doing the best job of it.

I typically use rice coal anthricite and bits of coke leftover from previous fires when I put it in the fire pit. This is what my forge looks like.

-

I use an asymmetrical mix. I use bitluminus to build the cave (as it cokes up), then I use leftover Coke and anthracite to refill the fire pot as needed.

-

I was curious to see if any else used a combination of anthracite and bitluminus coal. I like how I can control the fire when using both kinds (build a fire cave and keep the fire pot stoked). I have noticed that since using both kinds I have had no problem with clinkers and ash I'm not sure what happens to them but they don't build up in the forge.

Maybe I'm doing something "wrong"

-

Yeah, safety should be the number I priority. I think I'll have to wait and save my money to either buy a welder and take some classes or buy a commercially made press.

Thanks guys, I hope I didn't sound like too much of a fool for posting this design.

-

4 hours ago, ThomasPowers said:

4 inch diameter (ish) of high carbon steel is what I have currently. I am not sure about the speed of the pneumatic jack but I would assume it would have to do with the air compressor psi which is 150.

Are you trying to say that wood is useless in this application?

I am not sure about exact number for the failure mode of wood but it has to do with the number of knots in the wood. I was planning on making sure that I didn't use wood that was too knotty.

I have been considering buying a press new (as I cannot find any within driving distance used), but I don't really have 400$ to drop at the moment. If you don't think that making it out of wood is a good or safe idea then I guess ill have to sell a lot more hooks and bottle openers.

-

6 minutes ago, ThomasPowers said:

I wanted to be able to upset some of the larger pieces of metal that I have into a more workable billet. Also would like to try my hand at pattern welding. I would be using a pneumatic bottle jack so it should be quick and hands free as far as controlling the press (foot pedal).

As far as making it with wood it is what I have available at the moment. I don't have any beams or frames.

-

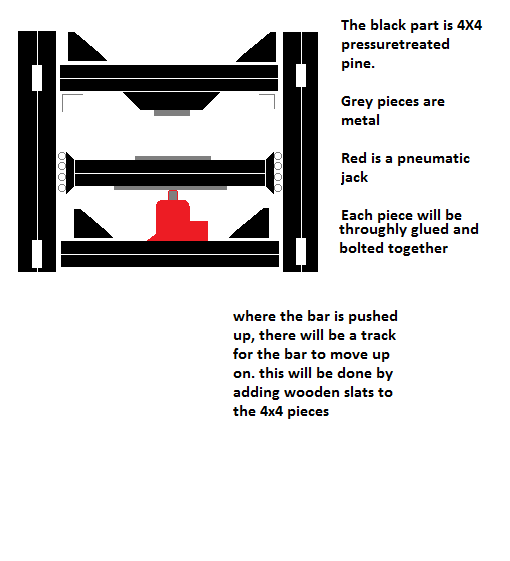

First off I am prepared to get a lot of negative feedback on this design as it is to be made out of wood mostly. Safety is the number 1 concern and I don't want to jump into anything I am not prepared for. I am planning on using a 10 ton pneumatic bottle jack as the power. From my research to the tensile strength of 4x4 pine ( I was not able to find much) told me that a 6 ft long piece has a constant load bearing of just under 1000 lbs when hung from the middle. This design is estimated to be 3 foot wide by 5 ft tall, and there is supposed to be an even distribution of pressure along the beams.

Any input is appreciated.

-

2 hours ago, ThomasPowers said:

Given any thought to bluing them?

I have not, I haven't attempted to color things yet aside from quenching in linseed oil. This is what the guy asked for and he is happy with them.

I have no experience pricing things where should I go to figure that out. (for future items, I already have a set price on these)

-

-

I'm not sure what ILL is but they didn't have it, I checked the whole system for the state and there wasn't any.

-

After looking at videos and posts I think I am going to use a slitter and make the hole that way.

-

I have, but like you said the price is too high. I just realized that I hadn't thought to check the library. I think I will do that today.

-

Maybe who made it. But with no serial number I wouldn't expect it to be possible.

When were Trenton's first started to be made?

Any information is nice, anvils are pieces of history.

-

I was at a friends forge and he had a cast iron mandrel and it was hollow inside. The wood might fit inside a similar type mandrel. Im not sure I don't know much about mandrels.

-

I did look it over as black frog said I couldn't find one. It was made before 1898 that is awesome. I wouldn't think that more information would be possible due to no serial number. Hopefully I am wrong?

-

I have been commissioned by a friend to make two twin axes. I have no experience making axes so I figured I would ask the experts.

He wanted them to be made completely of high carbon steel and to have a thick handle (as he has large hands). He drew something like this (the image from paint)

I have started one of the axes, I am using railroad connectors as my metal. My problem is not knowing the best way to punch through this metal and then drift it. I was thinking about drilling a hole through it but I am not sure if that is the best way to go about it.

-

On 11/27/2017 at 5:55 PM, ThomasPowers said:

Good Brand, most made in Columbus OH by the Columbus Forge and Iron Co. 258# for $500 is a GREAT DEAL on it as long as it passes the ring and bounce tests.

It passed the tests and I bought it for 400$. How can I tell where this one was made and when?

-

Assuming it is at the right height this looks like it should work well. You might want to cut off the ends that stick out of the bottom, as it potentially could be a tripping hazard.

Making it easy to move must be nice, I have considered adding wheels to my anvils but haven't done it yet.

-

This is one fascinating example of something that the romans invented that was only developed recently (Again). A color changing goblet.

-

Yeah I wouldn't think that recommending this is a good idea. It looks cast and the face plate on some of the newer cast anvils are made of steel that is too soft. You should be able to find anvils for about 500 that would last a lot longer than this one would (probably with better rebound too). Not to mention the stand is too tall so that would need to be replaced.

-

5 hours ago, Will W. said:

Please cite your sources. If it seems like im being rude, i apologize, i dislike misinformation.

Carbon nanotube article https://www.google.com/url?sa=t&source=web&rct=j&url=https://news.nationalgeographic.com/news/2006/11/061116-nanotech-swords.html&ved=0ahUKEwiL_IOOx9vXAhVH4IMKHSJOAh0QFggpMAE&usg=AOvVaw39LXSR4JucgEagLKE5mGCL you can also do a quick look on Wikipedia like SLAG said.

Spring steel carbon content .5-1%

Wootz steel carbon content 1-2%

Here are some of my sources

7 hours ago, DuEulear said:i used to believe in ancient super steel too then i learnd modern metalergy and saw the light

I'm not debating that we have better things now.

-

1 hour ago, SLAG said:

Please do not use the term wootz in relation to pattern welded steel. The term Damascus IS recognized for that steel.

this is what I was trying to say bothers me. I have noticed that some people are talking before they research things. It is all a learning process though.

-

This has been bothering me, it probably shouldn't but it does.

There is a difference between Damascus steel (wootz steel) and pattern welded steel. I have seen a lot of posts here and all over the internet that use the two terms interchangeably. Damascus steel historically was a superior steel to anything that was available (spring steel included). The original process of making Damascus steel was lost but seemingly has been found again. So getting the terms correctly is important in my opinion.

Fun fact, real Damascus steel has almost double the carbon content that spring steel has and during the steel making process carbon nanotubes are formed.

I am curious if anyone else has the same problem with the terminology.

-

I purchased this anvil earlier this morning and I was wondering if anyone could tell me any information about it. I didn't think to take any more pictures of it while I was at the shop. I looked it over and I did not find any other numbers than the 258 on the side of the anvil and the makers stamp. I have been looking around and I think I read that there may be a number under the feet but I don't relish the idea of moving it again.

thanks guys

Bitluminus and anthracite combination

in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Posted

It turned out that I didn't have any problems with clinkers was because they were collecting along the sides of the fire pot in a somewhat solid form.

My best guess as to why I didn't notice was because of the soil I used as fill for the forge. It has a high organic composition and was burning away at a slow rate being replaced with clinkers.

I recently had to take it all apart because the fire pot got too small and that is when I discovered what happened. I apologise for any misguided attempts at making a clinkerless fire.