-

Posts

276 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by GrumpyBiker

-

-

-

-

Has anyone polished Micarta & if so what grit did you go up to?

did you progress to a polishing compound as well ?

-

-

So it’s not the object, just words that were the problem.....

LoL, glad thats all sorted out.

I’ll save the G stuff for you & your group in the future & be sure to choose the most PC descriptions.

-

Someone will get upset ?!? I thought this was a place for adults.

Sad, but if the forum wants to ensure that people don’t continue to violate rules, a heads up (PM) removes any confusion.

* No Potty mouth, & no hidden weapons!

GOT IT !

-

That’s an idea.

Another idea is if the Moderators are going to remove a post it would be appreciated if they’d send a PM as to why.

Its as if knives are okay but these aren’t?

If we leave a note to explain some one will get upset, so we have been told not to any more, basically none of the knives have been posted with suggestions for them to be used to hurt people

-

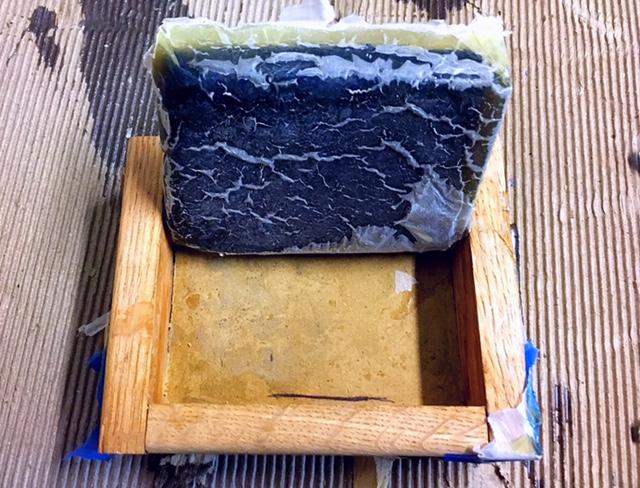

My fear of having to tear apart the 3”x9” molds was unfounded.

I glued it up so disassembly wasn’t really an option.

The floor wax made it come out without any issue.

One actually came out with the lid .

I now have three blanks to experiment with.YouTube Video link to the removal from the mold.

.

-

-

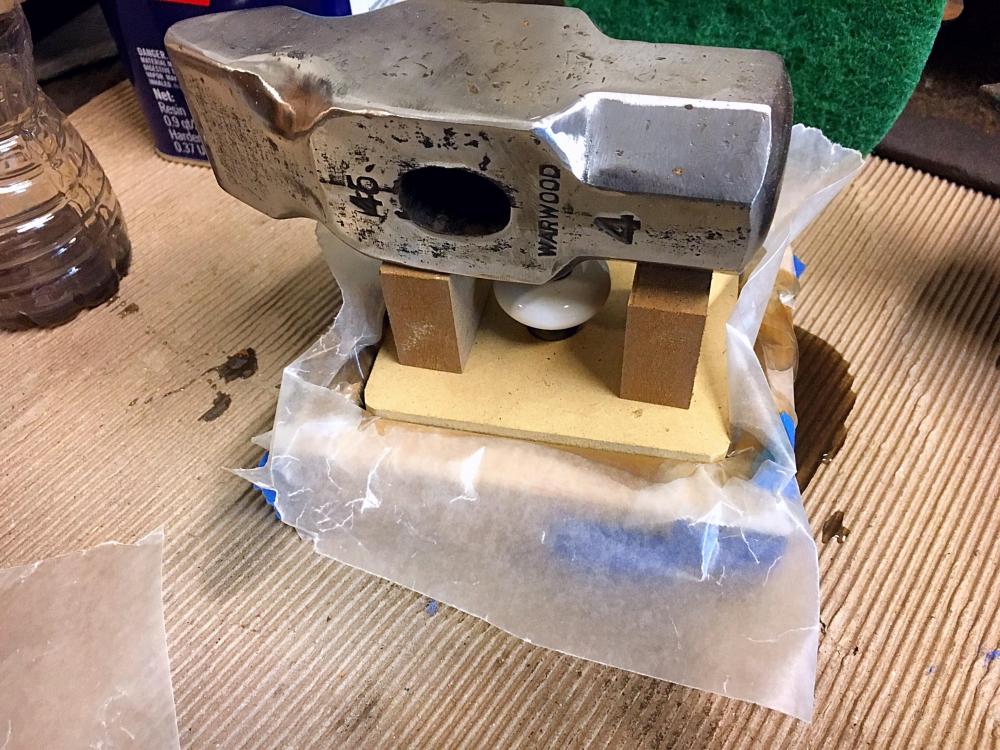

I decided to give it a go today.

As something different I’m attempting some Scotch Brite Micarta.I decided to make a mold that can be disassembled should the resin seep past the wax paper.

I also used floor paste wax to coat the inside of the mold to work as a releasing agent.

I found a scratch pad that’s 1/2” thick.

Way better than the thin ones as it gets thinner as it’s compressed.

I should be able to get a 3/8” thick piece of Micarta if it turns out.

Supposedly this type doesn’t need much pressure so I’m using a 4lb Warwood cross peen hammer head as a weight.

I also tinted the resin to more of a black in hope that it’ll make the blue stand out better.I ‘ll see how it turns out tomorrow.

-

Okay I’m quite sure someone on here probably has one but I actually do not know for sure what I have here, specifically.

In general I get it but I’m interested in knowing, with a link & or photo , what it is specifically as I’d kinda like to get the rest of it . If it is what I think it is.

Seriously, I’d love to know but consider me to be from Missouri , though I’m not, & show me!

I found this this at a junk store and bought it.

What is it?

1/2 of a bar clamp? If so I can’t find any pics or conformation.

From the color it appears to maybe be a Jourgeson product but there are no markings whatsoever.

As a woodworker myself I have lots of their clamps so if it is it’s not new.

The brass & color of the wood crank handle seems to indicate otherwise.

-

I think this weekend when I’m out in Berlin (Ohio) I’ll look for some chain that lays flatter.

Motorcycle chain would be fitting for me but I remember seeing a length of gear chain used to run a piece of Amish farm equipment.

I’m afraid to say it may have been from a manure spreader.

I had it in my hand to buy but put it back.

less than $10 , I should have brought it home with me.

-

I suppose I don’t know the correct blacksmith term but the use of a chain or item other than a Pritchett hole hold down to work as a third hand while forging.

I added this chain secured by a pull pin and weighted on the other end by a 5lbs cylinder.

I also had to add some angle iron to the edges as the chain was chewing up the edges of my anvil stand.

I’m interested in what everyone else uses.

-

Does anyone use anything as a releasing agent if you’re using a mold?

I was planning to coat the inside of my molds with Paste Floor Wax then add the wax paper on top of that.

Also I’m getting different answers so I’ll ask you guys, how much pressure is just enough as I don’t want to squeeze too much of the resin out.

I’ve seen folks simply set a paving brick on top & I’ve seen folks clamp it down tight.

* here’s the 3x9” molds I made from scrap oak & MDF. The lids are a loose fit to accommodate the double wax paper on the top & bottom.

-

sfeile - What resin did you use?

-

I went to JoAnn fabric today with my wife and didn’t even complain!

I bought 4 yards of three different colors and 1/2 gallon of resin.

I’ll be making a press frame this week (we’ll see how that goes) and hopefully get around to making some the end of this week or next.

I really like the look of the Rag style, but I’ll just bet that’ll be the one that gives me fits.

-

I’m going to be making some Micarta for the handles on a couple bottle openers.

This will be my first attempt at making it I will be making both a traditional as well as a rag style.

Does anyone here make their own ?

-

-

So is the consensus that these coils would be of suitable steel to make a corkscrew?

I like the idea of starting with a smaller piece vs cutting it out of the 1 ton leaf spring I was given.

-

-

The cork screw photo is one borrowed from the internet.

Not of my creation.

Ive not yet attempted one.

-

17 hours ago, tkunkel said:

Thanks. I don't have any experience with Flitz and will have to try it.

It’s just a jewelers polish.

10 hours ago, ausfire said:Grumpy: Classy opener, complemented by classy photography!

Refreshments in my wife’s study.

-

-

I just polish the metal & Flitz it to finish.

I used red oak stain & a marine grade Spar Varnish on the handle.

DIY Micarta

in Finish and Polish for Knives

Posted

Would this be recommended?