(M)

-

Posts

136 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by (M)

-

-

Good to know. Thanks. it has been interesting working with a propane forge instead of solid fuel for sure, but I really like it. The heat control and lack of fire management are great. I can be up and running in 15-20 min including setup compared to the 45 minutes with my charcoal. Now that the important stuff is done I hope to get it totally finished and experiment with different heats and the like. and of course get on to forging stuff!

Thanks again everyone!

(M)

-

Thanks Buzzkill! What pressure do you usually run the forge at? I keep mine just above the point where it sputters for an idle when i take the piece out, and i would guess 10 or 15 psi or lower for forging. I dont plan on doing much forge welding any time soon to be honest, but i do like to work mild steel at a lemon yellow.

-

Done

-

I Got it all pretty much done! Just got the zirconium in yesterday and did some forging. No legs yet. The only problem is it doesnt want to get yellow hot. Havent gotten anything to welding heat as of yet. I am working outside so that may affect my colour perception.

Should i need to max out the pressure on the burner to reach welding temps?

It is still running a bit oxidizing which i will need to fix, and my mig tip may be a tiny bit off centre but im not sure.

I forged the hot cut and hold down in that forge. It seems to heat up material quickly, but bright red/orange seems to be the max.

Any help is appreciated.

-

Congrats!!

-

Ahh i see. Sometimes there is some tedium involved. I personally found that time reading through it well spent. Its not easy stuff.

Have you checked out my thread? Its pretty simple, hope it helps

-

Read Forges 101 and Construction of gas forge in the gas forges section. All your questions are answered 100fold. No sodium silicate!!

Please Enlighten yourself at those threads for very specific info. It may take a while to read, but its worth it. Read Forges 101 first, or at least some of it to get the underlying principles, then check out Condtruction of a gas forge for specific step by steps. Burners 101 is very good, as well as Ron Riel's website. That will clear up your information there.

I asked a looot of questions in construction when i made it, i made my forge with almost exclusively that info and forges 101.

Best of luck!!!

-

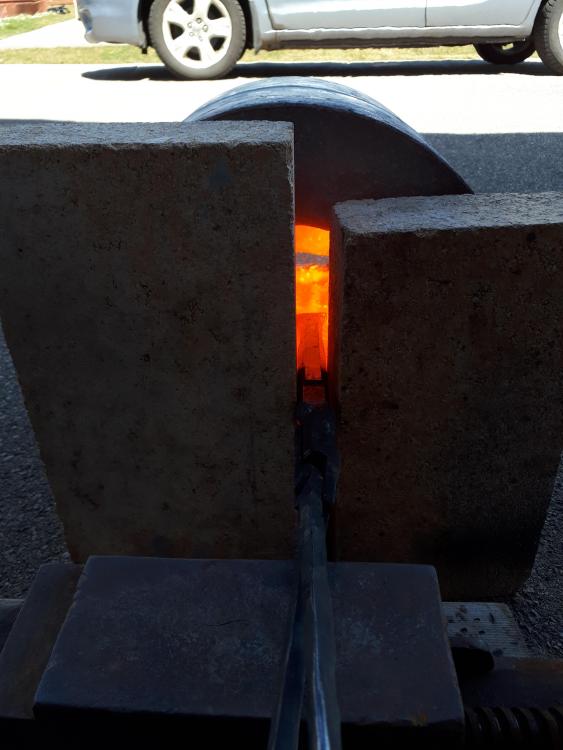

I got the kaowool in, successfully rigidized, and mizzou casted all around pretty much 1/2" around evenly. Curing untill tomorrow afternoon. It all went pretty smoothly, the burner FINALLY worked when it was in the forge to fire the kaowool. Thanks for all your help and advice, i put it into practice and i couldnt be happier with the way the forge has turned out so far. The picture is the firing of the rigidizing of the kaowool. I will post pictures after the curing.

@IronDragon Forge & Clay: sorry for ignoring you, the folks weren't comfortable at first with posting the location. I'm southern ontario, Canada.

Thanks again everyone !

-

They are 8 and 5 respectively, both are rescues. I think they are locked in...

Especially the older one, hes absolutely petrified, we think he might have been abused with a loud machine like a vacum. He's got an unexplained kink in his tail at the end. The other got hit by a car and got a broken pelvis as a kitten and she healed and we took her in

-

Nice! looks nice and looks like it would be a real workhorse!

-

-

-

I dont know how many people buy damasteel, most make their own damascus steel. Look up a generic tempering chart and see what you want to use it for, and just follow that. Axes are softer, filet knives are harder etc...

Best of luck!

-

Here's the near-finished dry-fit. 2" on the back, little shredded chunks to fill the holes that you can see. Im going to cut a small hole in the back and have a split blanket kaowool to flatten the floor profile. I forgot to wet it down when shredding the kwool so everything in my garage may be very itchy...

I am planning to have the burner horizontal at the top to induce a vortex so we'll see how that goes. Started on cutting out the hole in the tank, once i finalize the position, i will cut the wool, weld on the burner holder and i should be off to the races.

First pic is with just the outer layer, second is with full 2 layers.

To start, firebricks will be the doors, but once i get more kwool and time i will figure out a swinging door.

Please continue to critique!

-

Beauty!! Great job! Thats what i want to work up to!

-

Wow! Ausfire how do you do those?

-

Tbh i dont know how u did that can u explain?? I think i get how the fuller works but how is it useful?

-

Thanks for all the advice everyone! I really appreciate it. I think I am going to go with 4140 and / or whatever I can find at the scrap yard. I will look for things like forklift Forks and Axel's Etc and I I will test them and see how it goes. I will see how expensive 4140 is for me and if it's reasonable then ill pick some up for sure, but reclaiming old steel is fun too.

-

This sounds like really a lot of work when i could just buy 5$ more kaowool. Ill probably do that or see if what i have could work. Thanks for the input, i'll keep you posted.

-

Looks to me like air hose and ball valves look like they arent for gas either. Lol they use the wrong type of plumbing tee, and the bell reducers look like they expand massively too quickly. They even use teflon tape!! As said above, stay away! Make your own properly to get one that works and wont kill you!

Best of luck

M

-

Thanks! What dimension of shrinking should i watch out for? It will be like a "(" in shape, so will it decrease in diameter or length or just overall?

-

I'm lining everything including the kaowool floor with a solid 1/2" of mizzou, and i might get a kiln shelf if it doesnt stand up to use and possibly flux if i end up using it. I might just pour mizzou in the bottom then, because i have it and obviously it can withstand temperature. I might use sonotube( those concrete pillar pouring thingies) as a form. Thanks! Im just going with a simple round forge for now, and if i have something really big that wont fit then i'll probably use my JABOD or a stoked campfire.

-

Welcome aboard!

-

And people say blacksmithing is just heating stuff and hitting it

April's latest mount knives

in Knife Making

Posted

Nice knives!

First one:

What is the purpose of the choil-like thing on the spine? Is that for your thumb?

The joints look really smooth, and with a blade that thick it should be pretty much invincible!

Second one is not my personal style, but the fit and finish are spot on!

I only have 1 knife under my belt, and i hope to move up to some bigger ones like your first one. How much forging did you do untill you started grinding?