Kev walker

Members-

Posts

26 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Hi Joel The whole fing cost me £1300 but it’s all new gear I could of done it cheaper with used gear but I sold some workshop tool that I didn’t use. you can make hammers easy and that’s what I built it for I will be posting some videos on YouTube of me making an Hammer with it in the new year (Bishop Norton 1959 )so if you subscribe when I post it You will see it straight away and maybe I should’ve done a bit of a video of it being built and my Tyre hammer cheers Kev

-

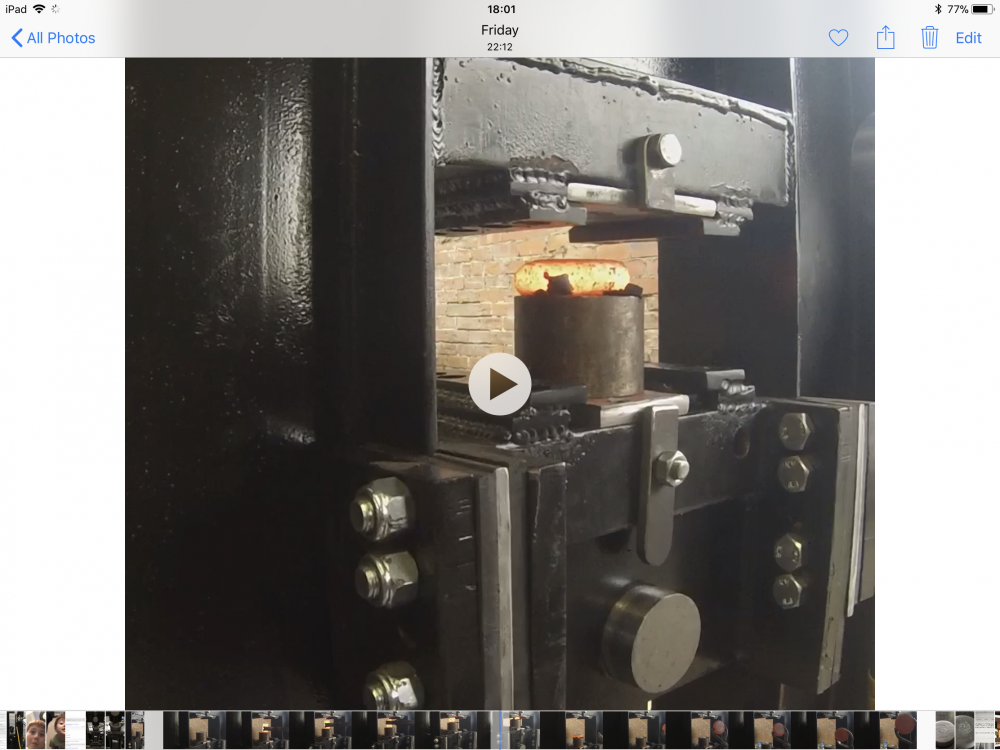

Press works well It works as good as I hoped it would the round billet was 1 1/2 x 3” mild steel It also punched a couple of hammer eyes did a good job I have a vidio on instagram #bisopnorton1959 if you would like to see it thanks for your help D2ADBDF6-1566-4812-9A5F-64AC987A9738.MP4

-

Many thanks i didn’t think It would be that much but thanks I’ll get my forge going in the week and see if I can make myself a Hammer, cheers

-

Thanks for your replies I think i must be dumb I can’t work it out the. I keep getting the wrong answer internal diameter of the cylinder is 5 inches it as an 8 inch stroke and the rod is 2 3/8 60 mm and 3000 psi It would be very much appreciated if somebody could work this out for me as it is giving me an headache thanks

-

Well I fired the press up I was pushing 3200 psi and a tad over a inch per second I don’t know what that means in tons can any one tell me cheers

-

Cheers I will I’ll see if I can put a link to a vid on YouTube

-

Thanks almost done just a few bits and I’ll fire it up

-

The bottom pin is 41 mm h13 and the top pin is 65mm I think 24t I don’t know what the equivalent will be in Canada but the guy at the steel place so that would be plenty strong enough we Shall see I think I will take them out after I have had a go with it just to make sure they’re okay

-

This thing is going on wheels just over 6 foot and 28” wide it’ll just go through my door . I don’t know if this motor pump setup will be ok got it off eBay the other day 3.7 kw 5hp 8gpm Hilo pump £200 should be able to give it a try by the end of the week with a bit of luck thanks for your comments The bottom pin is 41 mm h13 and the top pin is 65mm I think 24t I don’t know what the equivalent will be in Canada but the guy at the steel place so that would be plenty strong enough we Shall see I think I will take them out after I have had a go with it just to make sure they’re okay

-

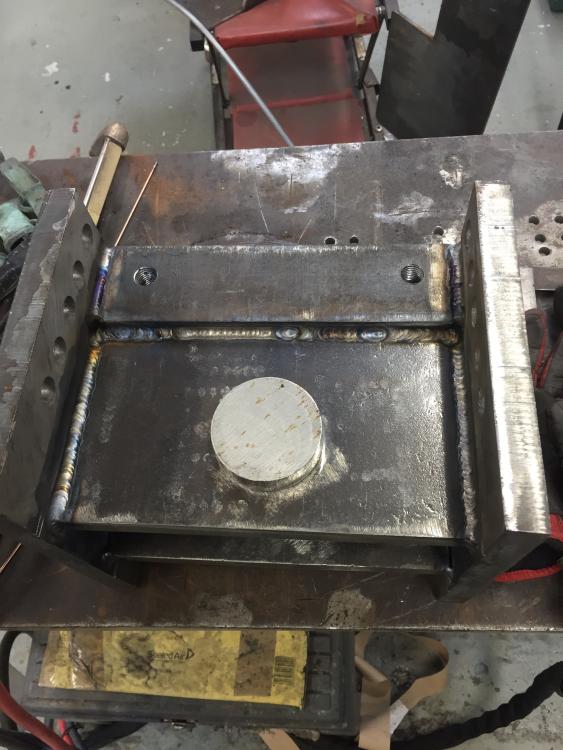

Well got a bit more done on my press almost done the frame and ram parts tig weld first to get a good bite then 2 passes with the mig welder Should be enough to hold it I can’t see it going anywhere should only have about 24 ton should have it painted before the end of the week

-

Cheers yes she is but now I’ve got to make my son a bearded camp axe If I get one done I will post it

-

Well ive started my build 8”x5” h girders still waiting for the laser cutting should have all the main welding done today i think I’ll do three welds on all the 20mm parts that should hold it together It Will add a 20 mm top plate and underneath the top H girder there will be a 60mm striking anvil block should be very strong