-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Andrew Collington

-

-

5 hours ago, Thief_Of_Navarre said:

I was about to chime in with this when I noticed you'd beat me to it.

Anvil looks in great condition. Is there any chance of a gander at the vice?

I don't have pictures of the full vice, so you can't see the leg which is slightly bent. But here's the main body of the vice. Unfortunately, the vice won't open any more than shown in the images. The thread is not lock - I unscrewed it fully and where it was inside the box it's just a lovely condition, so I greased that back up. However, the pivot bolt is absolutely rusted fast so I can't loosen and clean up, and I'm guessing that's the problem because I can't actually pull apart the vice myself to open it up. Maybe the spring is shot, too, I don't know. Oh, and the sliding handle does anything but - it's locked in place with rust, too.

I imagine I'll be posting up on the vices board sooner or later to ask questions and advice, after first having a look through the threads already there.

As for the anvil being a "Birmingham pattern"; was it intended for a different purpose to the "London pattern"? I'm asking just out of curiosity and to further my understanding rather than looking to replace my lovely anvil (I'm so happy to have any kind of anvil and the prospect of trying some forging, and I don't even have any kind of forge yet!)

-

Thanks for all your amazing responses - what a great community you have here!

So the things I've learned are that the anvil is fine and the more I use it pretty much the better the surface will become in terms of removing rust, a brush down with a knotted wire wheel is all it really needs, and if I grind it there's a special place in Hell reserved for me. ;-) But, really, you've given me great advice in terms of what to do in the short term of cleaning up the anvil, good idea of what to mount it on and how high it should be, and I will have a solid look through all of the posts here regarding the ball bearing test and mounts - probably should have done that before I asked all my original questions, sorry!

Much appreciate!

-

Hi all,

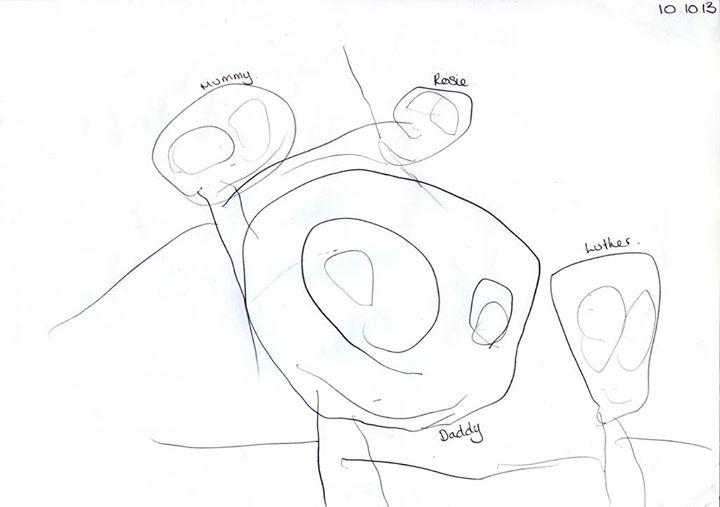

I am very, very new to anything forge-related, but the wife and kids recently bought be a second-hand and very rusty anvil and leg vice as a gift (along with a couple lessons in forging which I am very excited about!) But I honestly don't know anything about the anvil or where to begin in renovating it and keeping it good, or testing to see if it's OK, etc. I don't know the make (didn't see any markings on it, but then I wasn't really looking), nor the weight (other than it being in the range of, "oh hell no, I can't lift that into the car, are you kidding me?!")... But I'd like to make an effort in getting the rust off it, making it usable and then keeping it that way considering it'd probably be outside most of the time.

So where to start? I understand that a knotted wire wheel on an angle grinder is what a lot of people use, is that right? I've also seen people on YouTube use a grinding wheel but others not recommend it unless really notched. Also, should I use a sanding disc? Does the anvil surface need to be shining and flat? If I do grind, should I be weary about changing the shape of the horn or anvil too much?

I've seen people doing some kind of ball-bearing bounce test as well. Is that just to see how springy the anvil is in terms of how much your hammer strikes are likely to bounce back? Is it better to have a lot of bounce or not much? Or does that depend on the kind of anvil?

And for conditioning the anvil after it's clean I've seen people use (transmission) fluid. Is that OK? How often to rub it down if so?

OK, one more set of questions... What do people generally mount the anvil on? Would a tree stump at the right height (top of anvil level with knuckles, isn't it?) be OK? (I'm assuming any kind of tree so long as it's big enough to fit the anvil?) Or should I go some other root?

Like I said; I'm so green at all of this stuff, but really would appreciate any advice from people who have been there and done that, kind of thing (and hopefully on a small budget, too!)

Some images of the anvil are attached, if that helps any.

Thanks all!

Total newbie - where to being with this anvil?

in Anvils, Swage Blocks, and Mandrels

Posted

I have some penetrating oil and a knotted wire wheel on order today - hopefully get them tomorrow and will be able to give this another bash. Hopefully I won't need to buy a torch at this point and the nut will loosen enough, but good to know that's an option if all else fails - thanks!