droesse

Members-

Posts

9 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Here is a few pics of Brooks anvil I just picked up and the stand I made to put it on. The anvil is in great condition and the oil soaked sand filled legs on the heavy stand makes it a great combination. Takes it from an earsplitting ring to a dull thud.

-

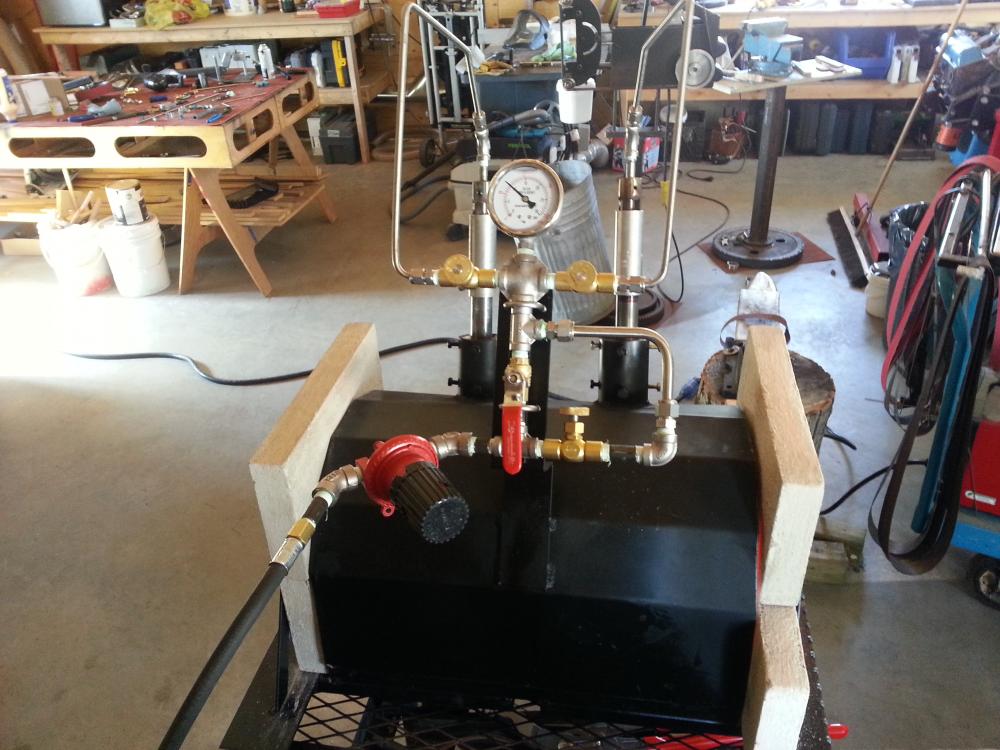

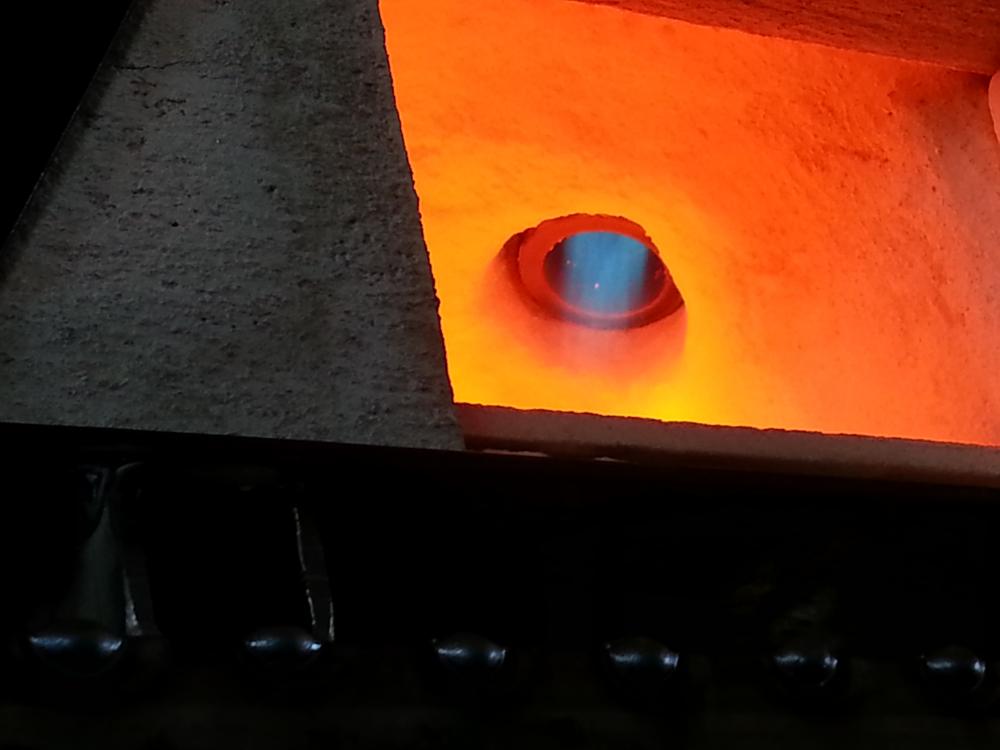

Thank you! I just finished the gas manifold today and only ran the 2 burner setup for about 15min. But I did run it with only one torch for about 3 or 4 hours the other day. I am using vermiculite board coated in ITC100 for the doors. This is not going to last very long so I am going to try bricks instead I think.

-

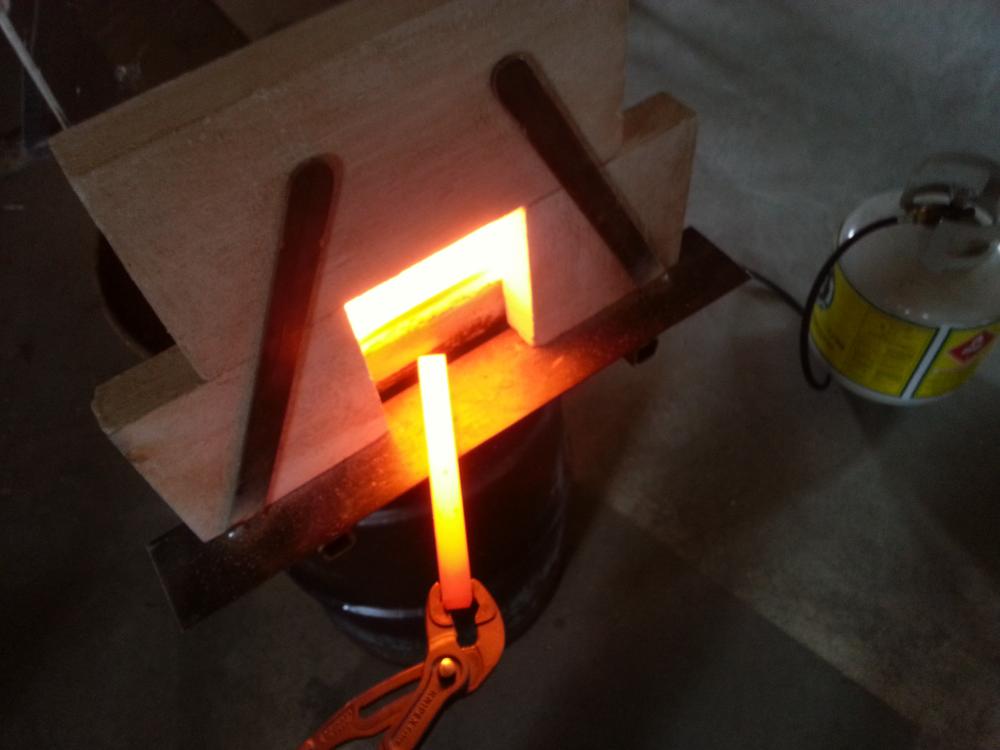

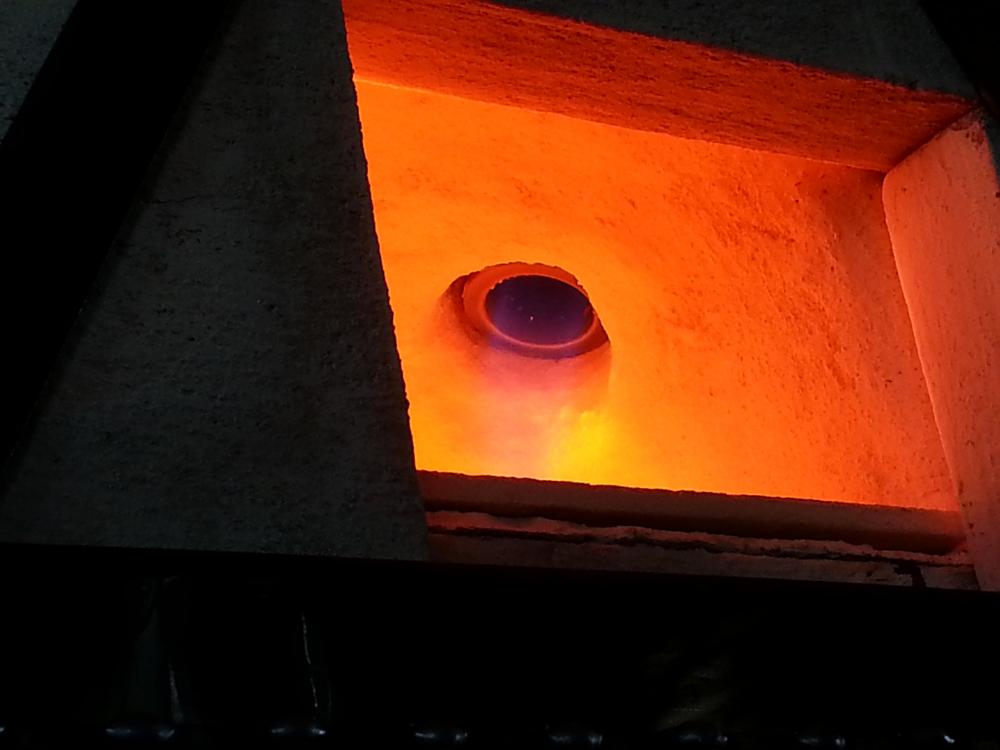

Just wanted to share my forge build pics with everyone. I gathered most of the relevant knowledge from people here sharing their experience so if anyone has any questions (or advice) please feel free to comment. Mikey I went with a smaller orifice in the torch mig tip like you suggested and it works much better. The last 2 pics show one of the burners at 3psi on the idle circuit and then at 10psi on the main circuit. The burner flames become almost invisible over about 5psi. I am very pleased with the outcome and just want to thank everyone here for their contributions to this site.

-

Frosty is exactly right. I had the exact same thing happen. Turns out that I put a second layer over top of a layer that was not completely cured. I had to chip off all the bubbled and loose stuff and do it again. Wasn't a big deal just an exercise in patience

-

Very interesting. I have obviously got some more experimenting and learning to do... Thank you so much for sharing your knowledge and experience!

-

I do have the bevels on the front and rear of the openings. I did play with the nozzle overhang a bit but I am sure that it could be better. Is that the optimal setting, 1/16" ahead of the point the burner will take? Just curious though, what is it that you see when looking at that flame that makes you think that it should be better? I just want to be able to see what you see so that I can better understand the process...

-

Hi Mike! Thanks for the reply, you have been a massive source if inspiration for me! I don't think it is too short though... I am using 3/4 inch sch 40 pipe so .75 x 9 = 6.75 inches. From the forward end of the air openings to the end of the tube is actually 7.25" so it is really a little too long. The air openings are exactly 2.75" and the nozzle is set to overhang 1.25". The nozzle itself is a sch80 1" pipe coupler that I machined to 1 5/16" on the lathe. Do you think it is worth the bother to shorten it 1/2" ? Or am I missing some detail somewhere?

-

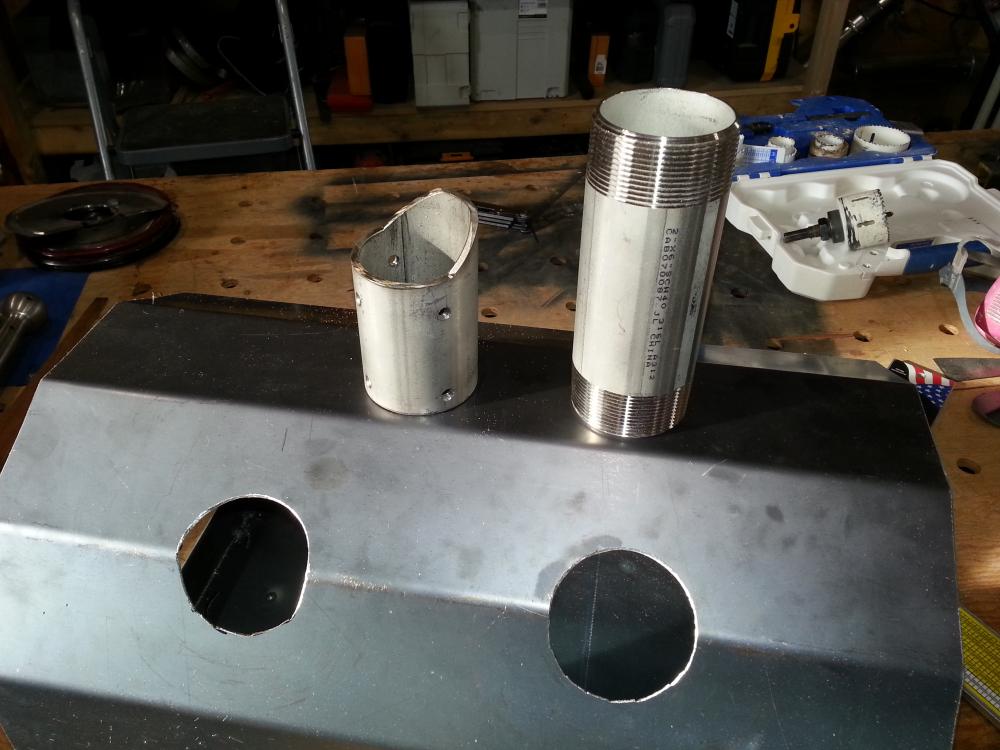

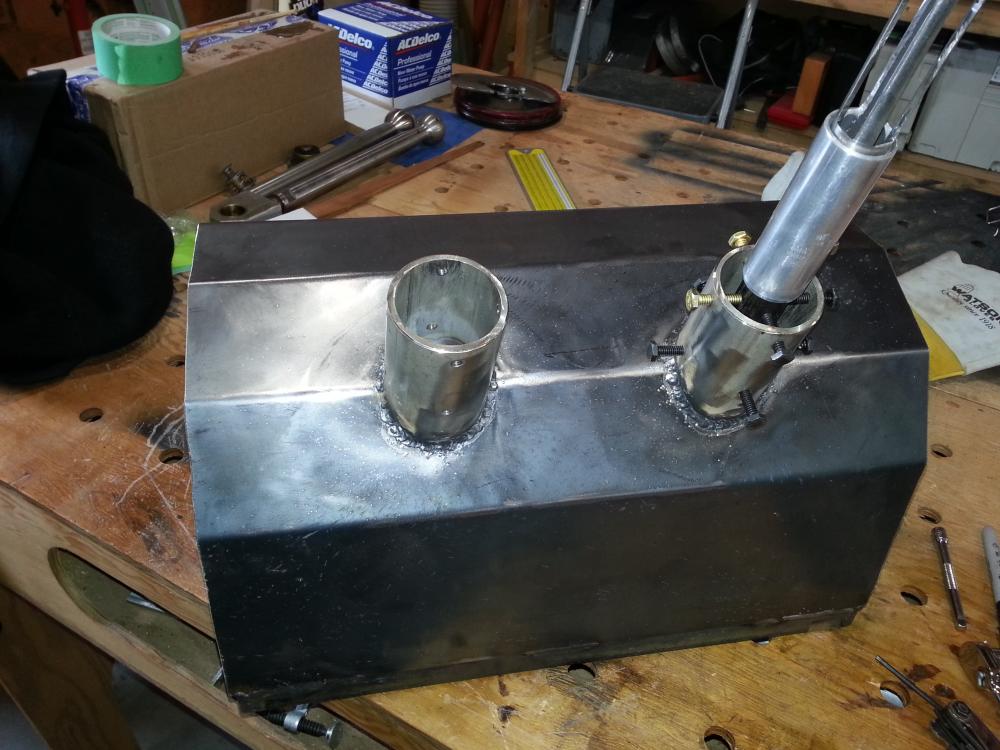

Hi folks! I have been reading this forum for a little while now and thought I would show you what I have created with all the great info here! I am starting a build of a 2 burner forge which I will document to the best of my ability and share with you in the hope of being able to contribute something back to the community.