S.Wright

-

Posts

29 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by S.Wright

-

-

Alright so I made some minor adjustments to the mig tip and shortened it a but more. I made all adjustments inside the forge. -

Roger that Frosty, I should have some time tomorrow to do more tuning which I will keep to only the forge for now on.

-

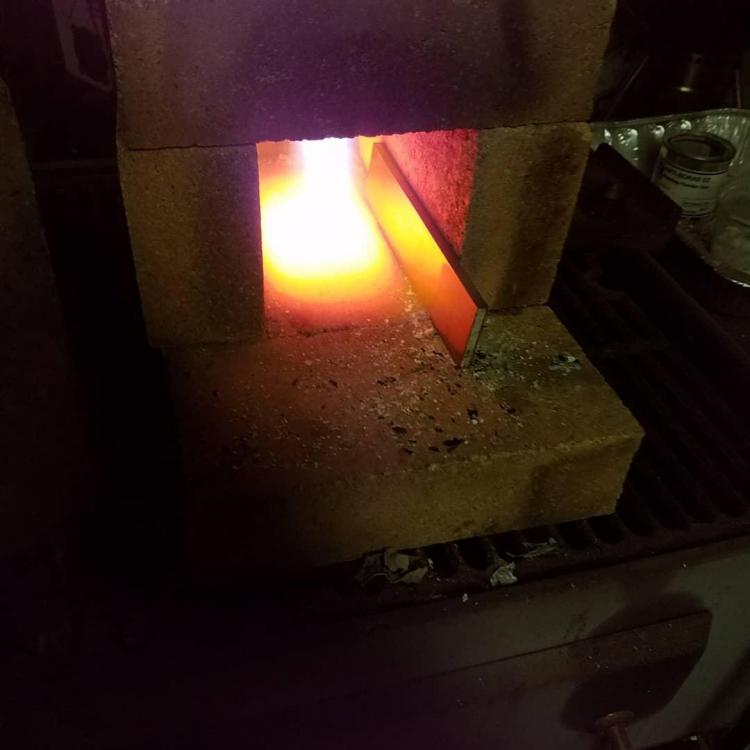

Quick question, I made my first T burner today straight from the instruction pdf. The only difference is that I used Lincoln 035 tips instead of the tweeco since I already had them on hand. When I went to tune it outside of the forge it runs great but everything is lost once I place it in. I don't have any video atm ran out of time. Here is my forge setup with a Reil burner running just to give an idea of what I'm trying to use it in. I will try to get video but it will not be until tomorrow. Thanks for any help

-

The rebound is excellent from end to end. I have been working with the 4x4 stake from oldworldanvils and I'm not used to such a excellent rebound and I had a miss strike and almost knocked my own head off. I'm registering it around 90% with a bearing and hammer drop.

-

Hello everyone, this morning I was able to pick up a mouse hole forge anvil. I believe I got it for a fair price anywhere, even more so in my area as most Vulcans in this area from 70+ lbs come in around 350 and up. I paid 400 for this, it weighs in at exactly 168.9 lbs, 1" hardy, 9/16" pircthel which appears drilled as opposed to punch as the underside of the heel is smooth. Serial number is still clear as day 14435. I have about 85 to 90% rebound. I only gave it a quick wire wheel to read the print and serial which happen to all standout great. I'm extremely happy with this purchase and was wondering what everyone thought and if anyone with better knowledge then me may be able to better date it. Also I did not find any deadspots it has a beautiful ring throughout!

-

I suppose you could have fluted the handle but I think it would hurt the overall apperance. The blade is great from tip to butt. I'm sure your elbowis glad that blade is finished!

-

Not the normal "coffin" bowie, but non the less it looks great, I really do like the guard design it looks comfortable.

-

Welcome aboard Yancy, I'm close, just south of Philadelphia in Nj. I use a simple propane forge and it works great. They are cheap to build as a second forge and are efficient when properly insulated.

-

That is ashame with the weld. The pattern looks great though. It looks like you still have a hefty billet though, is there enough material to cut the failure off and still use it?

-

Artistically speaking hands are imo the hardest thing to create. This looks really great and it is a great idea. Can't wait to see it lettered!

-

When you pull your blade out of the quench, if you are quick and easy on your pressure you should be able to straighten it as long as it is up above 450 F or so. I have also had success using clamps along the warp during temper when setting it on a true flat before starting.

-

The jointer I used was for sure the most dangerous tool I had. Complacency on top made it worse. I took part of my left index finger, bone and all off permanently with it. I recently traded that for a welder!

-

I was thinking if just purchasing a new empty they are only about 25 here so it isn't hitting me particularly well to just purchase a new empty

-

Would an empty propane tank work as well as a freon tank?

-

I will post a pic and possibly a video if I can later. I'm happy with what I have been able to achieve with this. And more burn is not up to date it is 1 1/2 x 3/4 with a wire hole instead of a mig tip tapped in. This being said I'm not looking to trouble shoot anything with it. I want to build a new more efficent forge that is also larger. Enough for a short seax and the like. Thanks again.

-

Sorry if this has been asked before. I have been using a Reil style burner in a plain old fire brick. I used the build from zoeller forge to give a better idea of what I did. Anyway I cannot seem to get it to welding temp and have been using this build well enough for about 9 months for mono steel work. Now I am trying to decide on a new build. So my question is are there any pros or cons for one style from another i.e. square, round, half round. I am going to be using frostys t burner as well in the new build. I am mainly focusing on blades and tooling. Thanks for any information.

-

Second from the left looks like a tie spike hammer. I have a bunch. I cut and formed one into a dogs head. It turned out fairly well.

-

If the knife is going to be used for the purpose of skinning I would go with wood or synthetic type handle. I find antlern, bone, etc make it hard to work with. Just my 2c

-

Shame about the cracks it looks really good otherwise. I also really like the low contrast.

-

Did you grind the round in or use a cupping hardy?

-

Hello all, at the current moment my vise option sits as an old non rotating bench vice. It is heavy duty and I have beat the xxxx out of it over the last 9 months or so and it has held up just fine, but over the past week I aquire an Erie Anvil Vise #44 for free. Is it possible to modify this into a leg vise or would it be best to just give it a solid mount and beat on it from there? Thanks for your help

-

Nice simple design for your first try. My first rr spike had the same look to it. It needs some more finish work especially on the bevel. I have been at this for only about a year I am still using files so I can truly understand the bevels and angles. But good job keep it up.

-

They scales are great I really like them. The mosiac pins offer a wonderful contrast in them.

-

Yes the Delaware Memorial. I'll have to look into them. I would like to meet some others that I can learn and grow from. Thanks

T Burner Illustrated Directions

in Gas Forges

Posted

Thanks frosty. I thought that the large amount of dragons breath was overkill which is why I made sure to get video tonight. I made my final adjustments by just filling so I'll keep that approach and knock it back a hair. I'm aware of the hard bricks poor performance. I actually just got my hands on and cut today the ends from a freon tank. I'll ordering my wool and coatings and all very soon to make that. Thanks a lot for the help!