-

Posts

349 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Zeroclick

-

-

6 minutes ago, Anachronist58 said:

Carbon arc torches were fun (for me) for heating and brazing 38 years ago, when I failed to protect my skin - got a permanent tattoo on my chest. Those things generate a broad arc and emit a LOT of UV.

So be sure to deploy adequate PPE.

Thank you for the advice I will make sure to take extra care when I use it might have to invest in a welding jacket.

-

25 minutes ago, Alan Evans said:

Don't fee too bad if you find it a pain...I could never get on with a carbon arc torch...though mine was a scissor action rather than straight slide to bring the rods together.

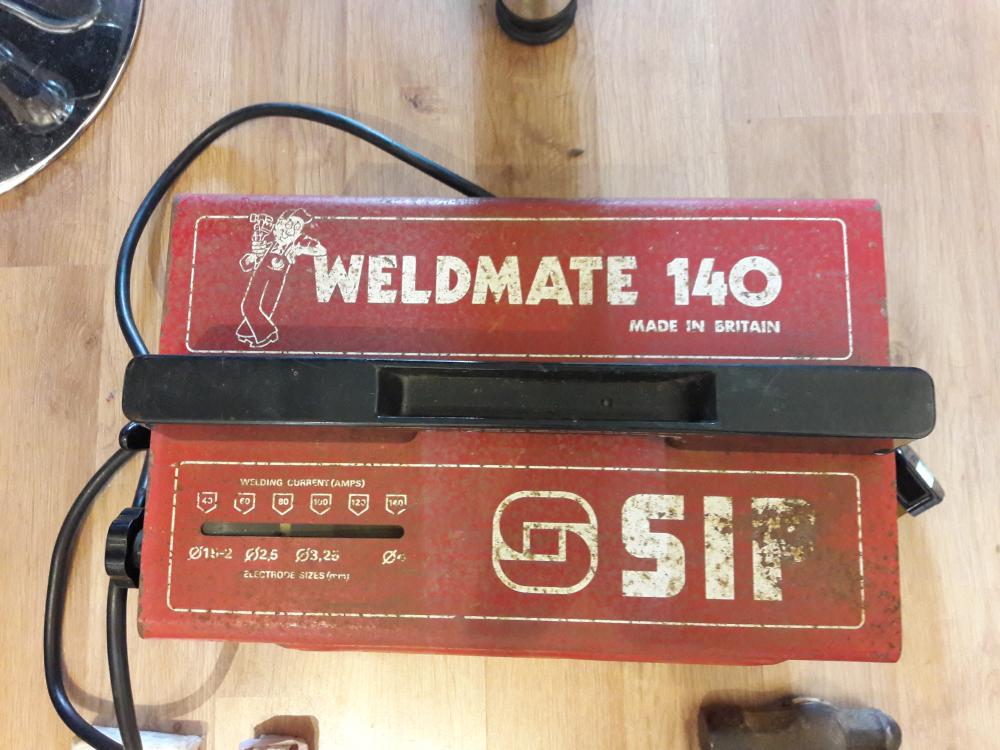

I learnt to arc weld on a SIP 140. It is not the kindest of tools to a newbie. Though a good welder will get the best out of it.

I would advise going to you local adult education centre/tech college and do an evening class on welding. You will get good instruction on excellent equipment and will save yourself much frustration trying got do it alone.

You will also learn to stick your rods in the bottom oven or on a radiator/night store heater so the flux coating is dry. Old rods can be a bit hit and miss.

Thanks Alan, I have been looking into a 6 week intro to welding course. It covers both arc and mig and looks really good.

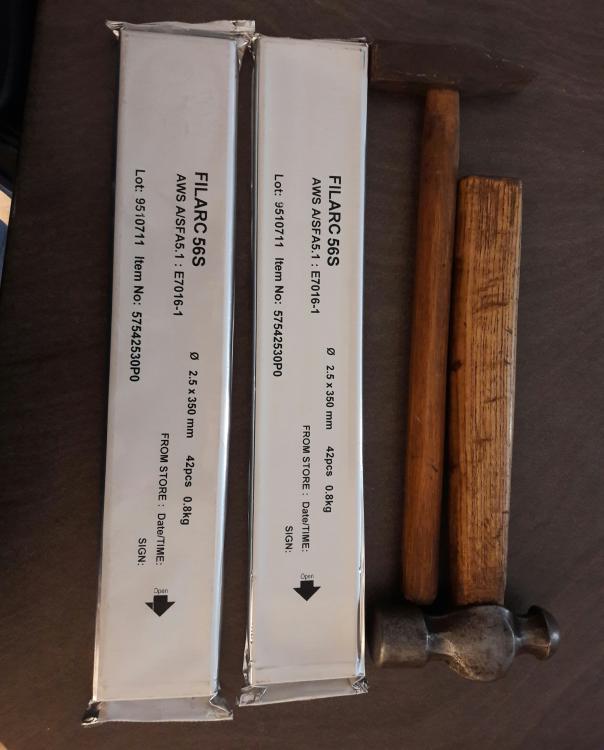

So I went to the other car boot and picked up the rest of the rods they are fully sealed so hopefully will be in good condition and of course while I was there I spotted a couple more hammers.

-

7 hours ago, arkie said:

That wrench next to the ball peen hammer is probably a Collins or Coes brand (Google "Collins wrench" or "Coes wrench"). If the wooden handle is in fine shape and the rest of the wrench is likewise, it can be fairly valuable. I picked one up for $17.50 at an old shop and found one in identical shape online that sold for $160. I now have two hanging in the shop, one a Collins the other a Coes. If it's in bad shape, it will make a fine twisting wrench if you weld a handle on the fixed jaw.

I will check to see if I can find anything, I got for twisting as they are smooth inside the jaws.

-

Cool thanks Smoggy, the guy who sold it didn't seem to know what they were he bought it because he thought he would get into welding and never did. I will put a pic of the other rods when I get them tomorrow.

PS I have just watched a video on using a carbon arc torch. It looks really good and something I will practice.

-

Ahhh thank you now I just need to learn how to use it

-

I have just got home with this lot, I paid £35 and the guy has said if I meet him tomorrow at another local sale he has about 6lb of rods he will give me to go with it.

The hammer is a 2lb ball pein and just what I have been looking for. The only thing I am not sure about is the item in the last photo I am not sure what it is called or what it's purpose is. Any information would be great.

-

Thank you

-

Now that would be fun to watch.

-

Those are really cool, do you mind if I steal the idea

-

This is such a cool trailer. I have been working my way through your videos and would never have guessed it was in the trailer seems so stable.

-

Love this design just seems really well designed. Can't wait to see it in action.

-

That looks really good, I really love the low layer count damascus.

-

1 hour ago, Frosty said:

Zeroclick. That's a boiler maker's hammer used to: flatten, dome. shrink, etc. plate steel/iron. Really nice addition to the blacksmith's tool kit, it'll make a fine sledge hammer sized rounding hammer. Good score.

Thanks Frosty that is really cool to know. I hadn't heard of that hammer type.

-

Thanks guys I was so happy to get it. He had two for sale the other was a 12 lb standard sledge but that had already gone. But he sold me this one for £1 and I couldn't have asked for better.

-

-

I use a stack of computer HDD magnets, I have two stacks of ten and it has completely killed the high end of the ring.

-

Nice anvil I have exactly the same one and love it. You might want some magnets on the heel to deaden the ring and your ears will thank you.

-

Yeah that may have been it but it seemed right by the colour. But to be honest I was getting to hot myself, so I have come out of the forge for the day and I will start a fresh when I next get in.

-

I made a hot chisel and rounded off a rounder punch as I wasn't happy with its profile.

I then tried to make a couple of leaf key rings, but for some reason I kept getting cracks along the transition from leaf to stem.

-

No problem.

Vinegar seems to be the best way to be sure you get the coating off. There is a thread about it if you search.

-

From what I have read it is best to keep Galvanised metal away from any high temperatures.

They should only be used for quench tanks, to prevent Zinc Oxide and even if you are outside it only takes small trace amounts to cause some pretty serious damage.

If you use google with site:iforgeiron.com galvanised , you should get a lot of threads on the subject.

It would also be good if you put your general location in your profile, you might find you live near a member, also helps with advice.

-

I just thought you say you are using a metal bucket for your forge, have you checked that it is not galvanised.

-

I personally use soil and then let the ash from the coal mix and it works pretty well and doesnt get any cheaper than digging it out of your garden. Builders sand can also be good it is what is used in side blast forges.

I would say don't use plaster of Paris or cement, I have seen a number of pieces of advice on here about pops in the platter or cement that can be very dangerous. Clay can be used the best example is the JABOD which is pinned in the solid fuel forge forum.

-

Welcome,

There definitely a lot of knowledge to gain from this site. Best to grab a cold drinks and something to snack on and start reading. The best thing to do if you are looking for a specific topic it is best to use Google by doing site:iforgeiron.com (key word of the topic) it gets you more accurate results than the local search.

Thoughts on forge name

in The Business Side of Blacksmithing

Posted

Hi,

So I have finally thought of a name for my forge that I like and would really like some feedback on what people think. So the name is Hand and Anvil Forge, the idea behind this is that all work will be done by hand at the anvil and it will also work as a touchmark with a hand print on my work.

Thanks for any feedback.

Zeroclick