GlennA

-

Posts

10 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by GlennA

-

-

Oh yes ... I will weld a "Sticker" or three to the pipe.

Thanks !

-

7 hours ago, JHCC said:

............. As for the depth of the duck's nest, more than a couple of inches is too deep. Check out the fire cross section diagram in the pinned post on "Forges and Fires"; you'll see that putting the fire too deep in the forge means that it's harder to get your workpiece in the sweet spot of the fire.

JHCC, I built an anthracite fire a couple of weeks ago ... & quickly found out that I needed a deeper fire to even get a Sweet Spot. This anthracite works nothing like the bituminous that I have fiddled with in a friend's forge a few years ago. My anthracite fire did not study the Fire Cross Section Diagram. Stoopid Coal ! 8^)

Thanks for the advice tho !

-

Glenn, 20 years ago, I worked a "Pittsburgh seam" here in Brooke county.Wv & worked a "Waynesburg seam" in Eightyfour, PA

I can't find a single source of Bituminous in Wheeling (about 20 minutes south of me) ... I would LOVE that ! Tunnel Ridge in Short Creek is only about 10 minutes southwest of me .... I've been thinking about stopping by & asking some questions. I know they belt all their coal to a river barge loading facility on the Ohio River. Wanna hear some irony ? .. I'm currently working right next doot to the former Wheeling-Pittsburgh Coke Plant in Follansbee, WV ... now known as Mountain State Carbon. They have MOUNTAINS of Coal & Coke piled up. Yeh ... I used to work in there too. Sheesh ... I could have had buckets of the stuff & no one would have said "Boo".Daswulf, I have a couple more "leads" to pursue locally ... but I may end up needing your assistance. Thanks !

I'm not chasing coal very hard right now ... just getting things taken care of before I need it ... getting things ready around here for winter ... & nursing a bad back.Thanks guys .. for the info & replies !

6 hours ago, Lou L said:Feed some schedule 40 pipe in and use a blower to feed air. The 400 blower will be your secondary blower for when you need more heat and the electric blower will be your maintenance air when using anthracite. You could still burn bituminous and charcoal with the 400 alone. It would be one heck of a flexible little forge that way! ........................................................................

.................... But he runs a blower into the intake of his hand crank blower and uses the blower as a booster (another option for you).

either way you do it you will definitely find that you need constant air.

I like those ideas Lou ! I am currently gathering up steel to make a new table for the forge .... I may incorporate the side blow into the design. This may help when I convince one of the local Coke hauler trucks that his tailgate latches need adjusted & I will do it along side the road ... for free.

I had actually thought of scabbing something over the 400 intake to tap into with a hair drier or such. I've got several circular magnets that may work like a peach ! This would also insure that the positive air would not be lost out through the idle 400.

Thanks for the reply Lou !

-

My plan is a Deep ducknest to keep this dang anthracite burning. That's why I have the clay so thick. There's actually two layers of 1.25" fire brick under the clay. I'm not sure the clay is gonna stick to the edges of the ducknest / bricks ... as it's a pretty thin coating & it already feels loose.

I'm already gathering steel to make a new square table ( .250 ) & .500" thick ducknest out of T-1 . This will allow me to use two layers of brick @ 2.5" thick ... & NO clay.Hopefully .... soon .... I'll be able to find a source for bituminous .. here in the "Land of Bituminous Coal" WEST VIRGINIA !!

20 Years ago .. I could pick up a sack of bituminous along the roads that fell off the trucks ... but no more.

-

Thanks for the reply & the flowers Kevin !

I have a piece of 7" diameter thick wall pipe. I plan on welding a 3/4" thick x 18" x 24" plate /table to the top & a gusseted leg hole plate at the bottom ... then concreting 2' of it in the ground. I think this will give me plenty of access around the vise ... & I don't think it will move.

This vise is 33" from under the top mount to the bottom of the leg ball.I also have two thick Street Grates that I plan on making a table out of .... any thoughts on how high I should make it ? Anvil Height .. or Bench height ?

-

-

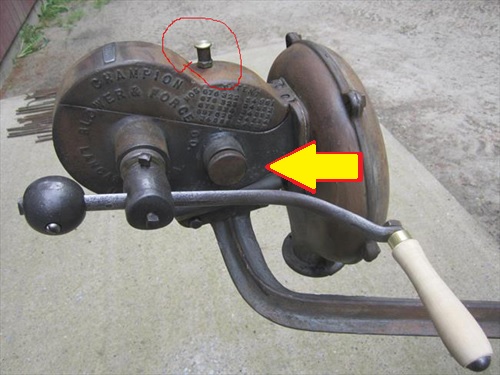

A very good friend of mine delivered this to me last Saturday. I had told him a few weeks ago that I was starting to dabble in Blacksmithing.

The only thing I can see that is hurt ... is maybe the movable side is bent just a little .. right below the screw hole. I will straighten it later if I feel it is needed.

I got the 400 blower back together & running smoothly .... got the 401 sheet metal pan all clayed up & a 3" deep "ducknest made for this darned anthracite coal. (only coal I can find locally) ... (yeh ... I'm in West Virginia .. northern panhandle town of Bethany .. for the curmudgeons) The State famous for bituminous coal !

134 lb Haybudden is rr spiked down to the stump. .... I'm almost ready to beat steel ! -

I need a grease cap for the sides / ends of the shaft the bronze gear is on. (Champion 400) The caps for the input / crank shaft is too big. I could also use a new fan ( my blades are badly rusted away). I'm going to try & repair the blades (sheet metal blades) with JB Weld ... any thoughts on this ? Will it work ... or fly apart & kill my dog ?

Anyone ever try to reproduce the tin blades & re-rivet them to the cast center spokes ?

Thank for any replies !

Hillbilly Newbie here

~Glenn

Almost Ready

in Solid Fuel Forges

Posted

Das, Ah yes .... Charleroi ... just north of the "Broken Bridge". I was just by there a couple weeks ago .. on my way to Greensburg to pick up a Craigslist 400

Could I ask you to contact me when you get ready to go buy your coal ? I may just meet up with you & buy a ton for myself.

Bituminous .... Right ?

Thanks !