-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Forging Fever

-

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

I made some progress on my supercharged 55 side blast forge as well. I made the opening in the side wall way to small so I will be cutting that bigger soon. Still haven't had a fire in it yet, but we are getting there. I still need to add a grate to the bottom of the fire pot, but I don't think I'm going to put a pipe under it as this is a side blast and all the ash will be contained under the 55 gallon drum that is the base of the forge. I used a drum with the top cut out of it and flipped it upside down. en cut an opening in the center to drop in my brake drum for the fire pot. I cut a 12" wide by 7" tall opening in the face of the chimney then cut in slots every 3" to create tabs around the rim. The first time I cut them the slots were to shallow and I had to cut them a second time. Finally I alternetly bent the tabs in and out to cradle the rim of the first drum. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

For anyone that was worried I was messing up my anvil here are some pics. The striking surface and bottom end of my bar stock anvil were not at all level and I cut maybe an inch total from both sides combined. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

Haha Charles, that excuse hasn't worked for me since the third grade. We moved up here from Denver area in '98. That first summer here was the last time I heard the phrase "come home when it gets dark." Well I rolled up to the house around 11pm mamma wasn't to happy. Frosty, I'm coming down for a Costco run tomorrow-Friday (possibly Saturday) can I come visit you sometime say, Thursday? I'll be staying on outer springer loop at my brothers house. I hope to make it by Pat's shop while I'm there too. I live across the street from a public park. We get kids playing basketball all night. The sun at night doesn't bother me but that thump thump thump sure gets to me. It wouldn't be so bad if the net wasn't a chain, but what you gonna do? In other news, I got my anvil cut flat last night!!! Thank god for friends/former bosses with access to a horizontal bandsaw! -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

My wife saw this post and informed me that this statement combined with being out until 3am this morning means I spent all my brownie points. Luckily I earned one point back this morning by sending her to work with a perfect cup of coffee. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

Nice one Frosty. -

Fuel Cost

Forging Fever replied to Forging Fever's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

You can't beat free fuel nice score! -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

I can get the drum fine. It's just finding the time to do it. I work a ten hour day at the airline and I still need to spend time with my family, this is how I earn points with the wife, not that I get to use them. Plus chores. I'm going to the boneyard sometime tomorrow with my coworker who is also a heavy equipment operator there and we are picking up a few for me to use. I'm thinking about building a retort as well... We will see. -

Fuel Cost

Forging Fever replied to Forging Fever's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

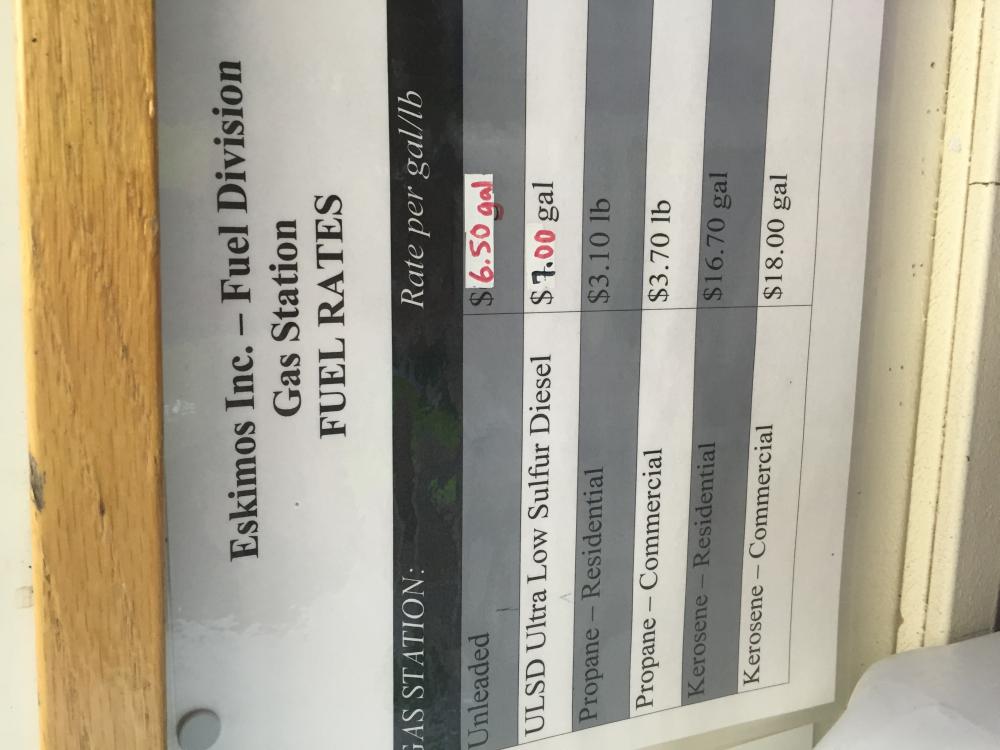

I don't know why the pic is sideways when I upload it, but below is a pic of the local fuel prices posted at our one and only gas station. We get all of our fuel once a year on a barge so the prices are set in August and do not change until the next barge arrives the following year. We are actually down $0.50 per gallon for gas and diesel from last year. -

I'm just curios what everyone pays for forging fuel. Tell me where you are, what fuel you use, and how much it costs. Oh and don't forget to add in your local Gasoline/Diesel prices. I live in Point Barrow, Alaska I don't currently have a forge but I'm working on a 55 forge that will burn free pallets. Our gasoline runs at $6.50/ gallon and diesel is $7.00/ gallon

-

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

Alright I will nix the used oil. Thanks guys. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

I was considering making a piece from one of the cutting edges into the top of my anvil but I think I'll wait to do that until after I get some time to have some one on one with Frosty. It will make an excellent anvil I am sure. I completely understand that all I need is something to strike on. I was watching a documentary on the traditional forging of Katanas last night and they had a pretty basic piece of steel for their striking anvil. Glenn, I am working on acquiring a 55 gallon drum for my 55 forge. I am going to be using pallet wood as my fuel as you suggested, and I was wondering what your thoughts are on adding used oil to the wood to make it hotter/more efficient? This may not be practical which is why I am asking before I waste time and effort on a hair brained idea. -

Blacksmithing gems and pearls

Forging Fever replied to Glenn's topic in Blacksmithing, General Discussion

From my maternal grandfather "Old age and treachery will win out over youth and vitality every time." -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

Yeah Tristan told me about the FB page yesterday I just forgot to sign in. I don't do Facebook all that often. I haven't logged in for years. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

My Maternal grandfather was a mechanic. I wish we lived closer to him growing up. It would have been amazing to learn that skill from him. He just turned 76 a couple days ago and doesn't get around very well anymore. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

Haha you have no idea! My dad was the supervisor at sanitation here for several years. Frosty, that is good to know. I will hold off from collecting anymore for now. My in at the heave equipment shop may be able to help me with cutting them but I will have to buy him some drinks later to find out. The pin from the loader arm may become my anvil horn at least for now. And I do hope to make a hammer eventually. I still need to get my hands on a "grownup" sized cross peen. Speaking of the class, would you be able to send me the details so I can figure out if I can make it or not? Thanks -Tim -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

scored some more metal! Above are 1 center and 2 corner cutting edges from the snow bucket at work. The mechanic just put on a fresh set before putting the bucket to bed for the summer, and he let me take the old set. Below is a tow pin off of a Dump truck and one of my busted claw hammers. The last three is a pin from a wheel loader arm at different angles. I think I'm going to forge some drifts and use one of the corner edges to make a heavy punch plate of various shapes and sizes. There are 10 holes already conveniently spaced to start the process. I'm not sure what I will do with the rest of it yet... -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

Well Little, judging by your profile pic, you would know. Thanks for the advice. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

Thanks Teeny, I really hope that I can make it down for the class. This is an awesome opportunity, It's kind of amazing that Mark is coming to Alaska right when I decided that I'm going to become a blacksmith. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

Thomas, thanks for the advice about the Heavy break drums. I will probably end up using them as base stands but we will see. Also I don't think that I will need to be looking over my shoulder for the "Great White" anytime soon. There isn't a tree around for hundred of miles. Yes I do know the value of insulation, its currently snowing as I type this. By the way, Frosty if you need refuge from that Birch the airbed is always ready. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

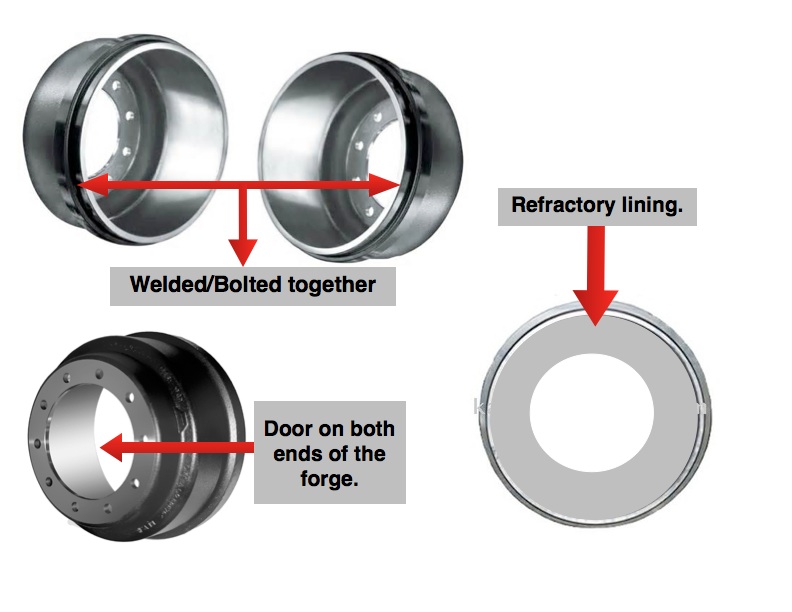

By the way that last pic I added by mistake, it was a diagram I made up for the Gas Brake Drum Forge I am thinking about making. Thomas brought up some good points about how heavy its going to be and I may abandon the Idea but I think I'm going to wait until I get my hands on brake drums to decide what to do with them. I will have a nearly unlimited supply of them once they thaw out of the snow bank. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

Alaska Airlines is practically a Pallet factory. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

I have a job of work to do before its ready but I am Stoked! I found it on the beach, when I first saw it I thought it was a piece of C channel, then when I tried to nudge it with my foot I realized it was solid steel. -

I caught the Bug in Point Barrow, Alaska

Forging Fever replied to Forging Fever's topic in Introduce Yourself

Here are the Pics of my stash minus the broken claw hammers (they weren't in my truck). I was wrong about the size of the cutting edge it is actually 1.5" thick not 3/4". I'm not exactly sure how I got that so wrong. -

My name is Timothy and I am 26 years old. I work for Alaska Airlines as a Ramp agent in the Northern most city in the US, and I have Forging Fever! Have you ever heard of Gold fever? Well it's exactly like that but substitute Blacksmithing for mining gold. Until about 2 weeks ago I never seriously considered becoming a blacksmith. "Hey that would be cool!" or "dang that's awesome!" and watching Forged in Fire on cable was about as close to blacksmithing as I was ever going to get. Then one day the switch in my head flipped and it wasn't just "that would be cool" anymore, it was "I have to do this!" For the past couple weeks I have been consuming every scrap of reliable information that I come across about blacksmithing. It fills my thoughts and my time. I have already started accruing various pieces of steel to use in my smithy. Here is what I have so far: 1 piece of steel of unknown grade 3"x8"x25.5" @148 pounds (this will become my anvil) 1 piece of used up 3/4" cutting edge from an old plow bucket (a section of this may be added to the 3x8 anvil piece to provide a Hardie hole, but I imagine that will come much later.) 1 piece of 1/4" X 3' round of unknown grade 1 tow pin from an old D7H CAT dozer (I plan on forging a cross peen hammer out of this. I also found a rasp file in the cab of the dozer) 1 bent crowbar (hex stock) maybe 5/8" X 3' with a rounded claw on one end. 3 broken claw hammers (to be forged into other useful things) 1 double faced hammer maybe 2 pounds 1 teeny tiny cross peen hammer with no handle (I'm guessing this one will be too small to use, but I'm listing it here anyways.) I will update this post with a picture of my accrued materials sometime tomorrow. So far that is it, but on the bright side the only thing that accruing this scrap has cost me is time and some gas, although not very much gas as my town is about the size of a postage stamp, but then again gas is $6.50/gallon at the moment. My coworker at AK Air also works for sanitation department of Public Works and alows me free reign of the equipment bone yard and metal scrap. He is also going to get me some left over refractory cement and fire brick from a recent overhaul of their trash incinerator. I'm very excited about that last part as I plan to build my own gas forge ,including the burners, the body will be two used up heavy duty truck brake drums that I was promised from a friend of mine that runs the Public Works heavy equipment shop. I also plan to ask him for a used wheel loader arm pin to make a horn for my anvil. There is no scrap yard or recycling center here so most of this stuff ends up in the landfill anyway. Other than work and forging fever, my time is spent at home with my family. My wife Christina of 5 years this September, and our son Liam who just turned 13 months old. Most of my family, parents and siblings, live in lower Alaska just North of Anchorage. I am looking forward to meeting all the other members of the Alaska Blacksmithing association that are in the valley near my parents home in Palmer, AK. I'm hoping to make it down to Anchorage in June for the class with Mark Aspery. I am very excited about that possibility, but my attendance of that function is semi-conflicting with an event that my wife has committed us to here in Barrow. It will take some convincing and compromise but I have my heart set on attending. I can hardly wait to start forging and I look forward to being a part of this amazing online community. P.S. Sorry if this was a bit rambly. P.P.S I use a lot of made up words such as rambly.