Teachagmech

-

Posts

25 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Teachagmech

-

-

12 hours ago, chris freeman said:

Does your forge have a way for gasses to get out? It looks sealed. You have to think of the whole thing like a tunnel not a tank. If you don’t have flow through the whole system, you’ll never draw in enough air to make it work correctly.

I would seal up the gaps around the burner tubes as the jet of flames is consuming oxygen from around the air intake of the burners.

when I want to hold in more heat, I set a brick in front to reflect the heat back, but still let’s the exhaust out. Using a refractory kiln wash also helps a lot with heat retention

-

Alright. I put together my stacked brick forge. Mounted the burners, cut two new mig tips to half the diameter of the tee for an air gap and fired it off. It's actually not too bad. Depending on if I have both ends open or not it will occasionally fall out of tune where the flame goes out and the gas is ignighted my the other burner. It's pretty hard to get a picture of that though so I put a video on youtube

-

7 hours ago, Frosty said:

Do you have pictures? Are you tuning in or out of the forge? How long is the mixing tube?

The distance the jet is compared to the brass fitting isn't too meaningful, it's where it is in the air intake ports that counts. In general I use 1/2 way looking straight through the air ports and usually have to trim farther back.

However if you're having to choke that much there's something else going on, it shouldn't be inducing air that strongly. I really want to see some pics please.

Frosty The Lucky.

I'll take some pics today when I get to work. We're on a pretty tight budget, so I don't have the kaowool and castable or the IR reflective coating to finish my "good" forge yet. I bought some hard bricks yesterday to make a little bench too cubby forge to make some stuff to hopefully sell at a craft fair coming up next month. I know they won't be as efficient, and the burners likely won't act te same as in the 20lb propane cylinder forge, but I'm just hoping to get a hang on how they're supposed to work. Buzzkill made a good point that I was overlooking: back pressure from the forge. I'll get an update and post back later today

-

7 hours ago, Buzzkill said:

Is what you're describing happening inside the forge or outside? It makes a difference.

Out. Forge isn't built yet.

-

14 minutes ago, Jasent said:

What pressure are you running at? I get stable fandom my t Buber at 9 psi but 12-14 psi is best in my forge? Are Y you using a 3/4"" t or 1" with 3/4" chase?

Anywhere from 4-25. Nothing would stabilize unless I choked it. Choked it was very stable through the whole range, but it lacked "fury" if that means anything.

I currently have 1" with 3/4" chase on them. I picked up the 3/4 on my way home. I won't get back to it until tomorrow.

-

On 8/2/2016 at 0:44 PM, Frosty said:

A PERFECT example of why you should NOT consult people in the internet. If you want to bring say 2,000 cu/in to welding temperature then a 1.25" T burner is what you want.

I've posted a T burner plan in as simple language as I my dented brain can and I had help. Just STOP talking to people who made something work or FIGURED OUT HOW to make one work. I figured out how to make and tune a "Jet Ejector" from simple plumbing and basic shop skills about 20 years ago.

If you want to build a T burner search out the Illustrated burner plan here on Iforge and STOP talking to other people. If yo need a hand ask me. The plans have the rules of thumb for the ratios to make different sized burners. The most important factor you MUST build to is the size of the forge chamber, it's VOLUME. Forget stressing over "I want to make damascus." You don't know how to make a pattern weld, how in the world do you expect to design a forge to do it in? Pick an established forge and burner design and use it a while. Once you know what you're doing is time to start tweaking things to what suits you best.

IF you want to try and figure it out on your own with the enthusiastic help of random people on the internet have at it, I'll leave you alone. I'm getting REALLY TIRED of trying to help people debug half donkey muck ups some random guy on social media "helped" them with.

Frosty The Lucky.

I'm going to drag up this dead thread to seek advice on my build.

I am making 2 3/4" T burners. I built them directly off the plans, using tweco .035 mig tips. The only difference between what I have and the directions is the 1/8mipX1/4 flare adapters that were available were 90* elbows. I used a milling machine to drill the holes in the tees. Indicated a piece of pipe to center, threaded the tee on, drilled, and tapped before moving anything. The jets point directly down the middle of the burner tube.

I forged out merchant couplers(thread protectors) to mimic the rough 1:12 taper for the flare nozzles.

The problem I'm having is getting the flame to sustain off the end of the nozzle. I have to choke one side completly off and almost 20% of the other side to get it to stabilize. It seems like the gas orifice needs to be further into the burner tube. I tried trimming it down (in vain) thinking it needed more space to mix and more air. I trimmed it all the way down to about 3/8" from the face of the brass fitting.

after fiddling with that for quite some time(including trying .030 and .045 mig tips since I had them) I finally pulled the gas apparatus out of the burner, pulled the tee off the end and held it in place in the burner tube while a few assistants helped with lighting and manning the gas valve. I was able to get a much bluer, louder flame.

I'm at a loss. I bought some 3/4" tees hoping to get the mig too closer into the burner tube, but I'm not sure if they will work.

I know YouTube is not a reliable source of info, but my flames do. It resemble those of other t burners I've seen. My flames look green. If I add more air(or choke less) the flames go out.

Thanks!

-

what did you make the stand out of? sure looks pretty! I'm in the market for a new anvil for work

-

20 hours ago, arkie said:

Can you do a google search for coal mines in your part of the state or maybe across into NV or AZ?

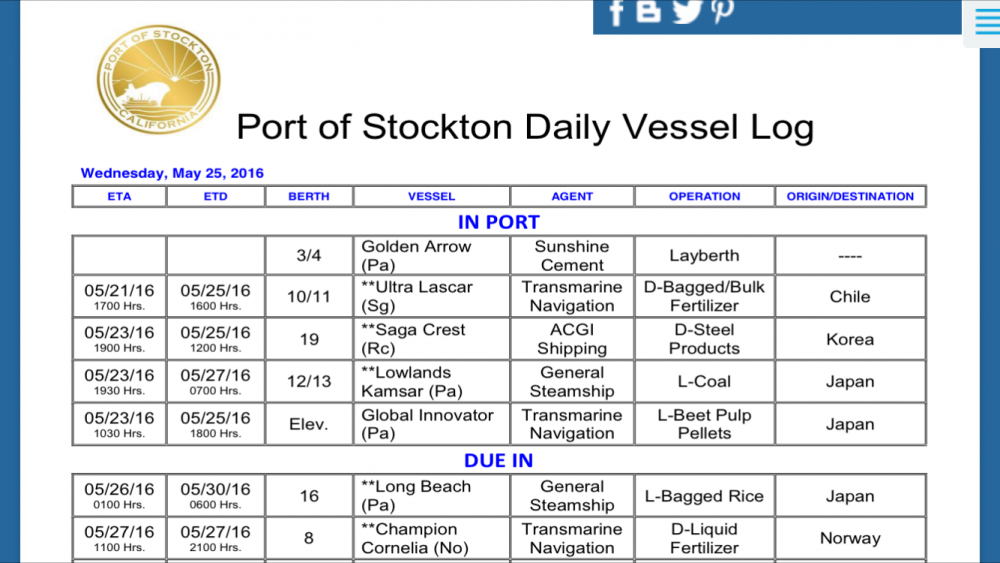

Well I called the port today to try to play the teacher card. I'd really like to bring forge work back to the high school shop. From my house, it 30 min to the yard in the port. I doubt they'd miss even 200lbs in a 55gal drum.

-

34 minutes ago, arkie said:

ARGHHHH!! Disappearing posts are back! Trying this again.

Some smiths get together and buy coal in bulk. If there is a mine or coal company within reasonable distance, you could use a trailer, dump truck, etc. to get the coal to a depository convenient to the group. From there, the smiths could purchase and load their respective needs. Cost would have to include coal, mileage and rental costs if a rental trailer was used. Gotta be cheaper than $25 to $50 per 50# bag plus shipping. We get our coal using a trailer capable of carrying 3 tons. Ours is about 160 miles away. I think, from reading their newsletter, that the Saltfork group in Oklahoma may stockpile theirs for members in two or three locations. The members then purchase and load out their own. Maybe there is a Saltfork member on IFI who could elaborate on that.

I know there used to be a coal seam about 50 miles from here, but it's all since been shut down by green do-gooders from San Francisco and Los Angeles. 30 years ago it'd be easy to get. And if liberating a few pounds off a railcar wasn't a felony I'd have a ton by now. There's a siding across the street from me that frequently overnights coal trains headed for the ports. Too bad they don't sell to the public.

-

34 minutes ago, arkie said:

I ran out of coal once and decided to try hardwood lump charcoal. Fire fleas nearly ate me alive. No more charcoal for me. Now, I just stockpile coal so I don't get into that mess again. Some folks use charcoal and love it...just not my cup 'o tea.

It seems like as soon as the fire fleas stop biting the charcoals gone. Around here my worry is set in the countryside on fire. The $25 a bag for Coalsounds like it's hard to be worth it too. Heck buy it from Centaur Forge for $50 a bag doesn't sound that bad for what I paid for the charcoal

-

Alright, so it works!

but man does it ever make a friggin mess! The ash fireflies are a real b&*[#! And they don't feel really good when they fall on your arms

end of the hour I've decided I definitely need to cut the firepot down. It's way too deep. I can only get to about 5-6" of material in the heart of the fire. I really wish I had a bag of coal or coke to use. I went through 20lbs of charcoal in about 90 minutes. I also want to put a smaller fan on it. The blower is WAY too much air. As I thought.

-

14 minutes ago, Buzzkill said:

You may not have seen it yet, but there's a whole thread on coal at Tractor Supply. In my neck of the woods it's about 6 dollars for a 40 pound bag in either rice or nut size. It's anthracite, so not ideal for smithing, but easy to get and reasonably priced - assuming you have a TSC nearby.

I've tried. I saw the thread, checked it out. No dice here. They can't even order it. Which kinda pizzed me off a bit since TSC is literally 12 miles from my house. Loomis is a solid 2 hours. Maybe I'll get a friend who's going to Colorado for deer season this year pick me up a couple 4-5 bags on his way home.

2 hours ago, 7A749 said:I'm going to do some looking around for some coal here. Just for kicks anyways.

I did fire up the forge today tho and hammer on some stainless! Still needs more work, it's an embarrassment right now so I'll skip a thread or pix

Look forward to seeing what you come up with Mike.

I'm not super happy with my forge table right now. My last band saw blade bit the dust at work the other day, so building a real table isn't in the cards this school year. I've got it tacked to a makeshift repurposed table thing I pulled from the scrap bin. It's pretty bad and a tad short, but it'll work for now until I figure out how to swing a hammer.

Well give 'er 'ell in the mornin tho

-

I picked myself up a 20lb bag of mesquite lump charcoal for $12 today. I found a place to buy coal and coke for $25/50lb bag. It's about as good as I can find.

If I ever get up by Loomis, CA I'll stop in and get a bag. I think the consumption of coal/coke would be less than that of charcoal and it's the same price. I also like that coal doesn't send off fireflies like charcoal does.

Any my input would be helpful. If i like th charcoal and there's not much benefit to coal over charcoal, then I'll build a retort and make my own.

-

16 hours ago, 7A749 said:

I've never used a coal forge at all. IFI member Heap of Jeep has graciously invited me to see his forge sometime this summer. I plan on bearing gifts when I go

Itll be interesting to see how yours works out. I know a young man here in town who uses a very simple charcoal forge with a hair dryer and says it works pretty nice. I don't think getting coal here would a problem, but I don't have the room for a true coal setup at the moment. Not to say I might not try and make room in the future. Propane and oxy fuel have worked ok so far.

I've used the oxy fuel method a lot at school, but it's a pricy heat source to say the least.

-

On May 16, 2016 at 10:52 PM, setlab said:

Why do images disappear from these old topics? So frustrating when there is an interesting topic.

On May 16, 2016 at 11:16 PM, the iron dwarf said:the forum has been upgraded and lots of stuff was lost

That's why I host my pics on photobucket. I've had too many things lost to "updates". I'd like to try a smaller version-- say a 1/4 barrel size maybe

-

1 hour ago, 7A749 said:

Hey Mike. Glad to see you here. I just joined too. The forge is coming along nicely. That blower you made looked quite capable of providing enough thrust to get to the moon. Looks like the grinder motor will work just fine tho.

Just got my little forge out and cleaned up today. Hope to bang on some metal soon.

Me too! As I'm finding here in central California coal is nearly impossible to come by unless I want to pay extortionous amounts from centaur forge for a bag of coal.

I think I'm going to keep the pot deep and use lump charcoal

1 hour ago, ThomasPowers said:bodark as it's a corruption of Bois d' Arc or Bow wood. Indigenous cultures used it a lot for making bows. Not southeastern as it's quite common in Arkansas, Missouri, Oklahoma, Kansas,... I have some from 80+ year old fence posts that takes a deep golden colour with flecks in it when hand rubbed with many layers of tung oil. UV will turn it brown though. Bodark was also a dye wood but a bit fugitive.

38 minutes ago, SLAG said:Thomas,

I agree with you. Osage orange is a beautiful wood. But the fact that it darkens considerably with age has always made me ignore using it for many years. But about 3 years ago I read that Woodcraft co. was carrying a different species of osage orange that "tends to keep its deep golden orange color".. The American specie's scientific name is Maclura pomifera. The Argentinian's name is Maclura tinctoria. The origin of the wood is Argentina. I have bought some and I will use it in the near future. But it will be years before I can see if the claim is correct. Woodcraft is no" bargain basement" if some other exotic wood seller sells It, it will probably be cheaper. So a net search is a good idea. Woodcraft carries many great tools and other items and their catalogue is worth a look, for anyone doing woodwork (or using wood.)

Regards to all,

SLAG.

32 minutes ago, ThomasPowers said:Using a UV resistant finish will also help

Sounds like some neat stuff to work with but I'm likely a long way from using any of it.

I'm thinking of a table something close to this

maybe without the lip? I'm not sure yet

-

6 minutes ago, TwistedCustoms said:

Osage is a hardwood, aka bodock, aka horse apple.

Seems to be a south-eastern thing. I've never heard of it. Looks really nice when it's all done up though.

-

1 hour ago, TwistedCustoms said:

The clinker breaker won't see any action with the floor plates but I like your idea about raising the floor. Maybe weld a short duct extension to the bottom of a plate sized to drop in and rest at 2.5-3". Your pot is good as is without any floor plate, it's just a little deeper than it has to be for coal or coke. Forge with it as is and see if you like it, you can always try the drop in floors later.

Nice knife, is that osage?

I'm not sure what you mean by Osage. It's a simple file knife. Applewood handles with copper pins. Cold chemical blue finish.

-

Frosty: yes, table is to come, but like i said, I want to make sure the firepot is correct before the table goes down.

TwistedCustoms: thanks. That's what I was thinking. From what I've read, charcoal forges require a deeper coal bed.

is there any merit in building another false floor to brim the bottom up rather than cutting the top down? This way I could pull the mid-way plate out of the firepot and forge with charcoal? Just spit-balling wondering if my ideas will stick. On those same lines, would there be any advantage to increasing the air blast area if I did put a false floor in the firepot?

On 5/20/2016 at 7:47 PM, Frosty said:That is almost too pretty to use. You do realize most of us started with a hole in the ground, a piece of pipe and a hair drier we stole from Mother when she wasn't looking. Right? Well, I did anyway, literally but fortunately I was smart enough not to take her new hair drier. This was decades before "blow driers" . . . still.

Table next, yes?

For what it's worth, my first forge was a cap from a piece of 16" flange pipe with a chunk of pipe taped to a garden hose with a leaf blower taped to the other side. Made this file knife with it.

there are a lot of things I'd like to improve on, so I need a new forge.

On 5/20/2016 at 7:50 PM, TwistedCustoms said:It may just be the perspective in the photos but the pot looks really deep. Four inches will give you a big fuel mass for sure. Unless you're going to be forging three inch stock daily you could get away with trimming it down and save some on fuel. Great job on the fab work, I look forward to seeing it finished.

-

Well, I'm new here, and so far, I've learned a TON of stuff from the forums here at IFI. I've always been fond of blacksmith work and the smell of coal burning. I've also taken an interest in bladesmithing(who hasn't in recent years) so I wanted to build a forge. A gas forge would have been neat, but the nostalgic draw of coal has brought me in that direction.

At first I was going to build a hand crank centrifugal blower, but that ended up a bust when I found a half-broken 6" bench grinder motor. the shaft was true, but one side guard was broken and with it a healthy chunk of the bearing support. It wasn't going to be any good for a grinder, but it was a 1/2 HP motor for free...and who doesn't like free!?!!!???!!! so I dug up some stuff on the hand crank blower build thread here, went and did some of my own research, and sprinkled in some of my own ideas and this is what I came up with:

then came the fire pot with a makeshift clinker breaker

and a Tuyere

then came the charge air pipe with an ash dump at the bottom

I don't know how effective it will be, and I'm a little worried of fire pot being too deep, but I can always cut it down. If anyone has any input on that, I'd love to hear it since I'll be starting on the table on Monday and would like to be able to move forward without taking steps backward. at this moment, the pot is 4" deep, 9" wide at the top, and 13" long at the top.

Hopefully I'm not too far from where I want to be(or where I should be).

thanks in advance for all your help and suggestions

-

alright, well I have success! my blower Jr has a 7.5" diameter wheel. its driven off of a broken bench grinder motor. the smaller fan size allows the grinder motor to come off the start cycle, run at almost full rpm, and doesn't show many signs of getting hot. I've fixed a shroud around the motor to direct the intake air over the outside case of the motor to help aid in cooling. its a bit noisy when running open with no restriction, but quickly quiets down when a load is placed on it. Now to build the forge!

as you can see below, the grinder motor has seen better days. the guard broke off and took a chunk of the bearing support with it. that side is pretty useless, so I just cut the end of the shaft off.

The intake shroud is 22ga galvanized sheet that I had lying around. I hemmed the edge and sent it through the roller to kinda match the radius of the snail.

the tab tack welded to the end was just to add a little load to the fan to quiet it down. i also recut the cover plate to restrict the intake air to the motor side. I ended up cutting the other opening larger.

still to do:

replace the power cord

build the forge

make fire

shape metal!

-

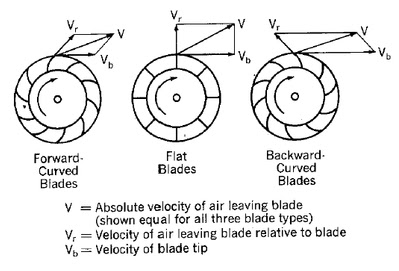

Bewildering is an understatement! I'm fascinated by them. Don't know how variations do what they do, but it's neat to see.

Update:

the poor little bench grinder is gonna burn up before the fire ever gets hot. I bent the vanes about 30 degrees further, rebalanced the rotor, and noticed a pretty substantial pressure increase. Not as much air, but is much more resistant to cavitation.

I'm gonna make a Jr version. Closer to 7" I think.

-

well judging by the calculations earlier in this thread, somewhere in the neighborhood of 2000 rpm. if I can get away with lower, i'll reduce the speed by either a speed control or rigging a jack shaft and belt drive. Like I said, if nothing else, its a fun project to say I've built one.

Also, the backward spiral on the vane design can increase the air velocity at the tip of the fan blades, thus increasing pressure. I may end up going for a 3rd revision on the fan blade assembly and making an even steeper backward pitch to lessen the volume of air, but increase the pressure at the outlet. I'm not a fluid engineer either, but this is what my research has lead me to believe.

The rotating portion of the fan is only made of 3/16" plate and weighs only slightly more than a new grinder wheel. If I burn up the grinder motor, I'll know it was too heavy.

if it works well enough but is too big, I can always build another smaller version. Like I said originally this was going to be a hand cranked blower so I was looking for larger diameter to get the critical blade speed with lower RPM. Now that I'm putting a motor on it, I can easily go smaller which would be less strain on the motor which will let it run closer to its no load speed of 3600rpm.

-

Alright, nothing like reviving an otherwise dead thread for my first post!

I'll start by introducing myself:

im Mike. I am an agriculture mechanics teacher at a high school in central California. I'm not a blacksmith by trade, and that'll be pretty apparent if you see any smith work pics of mine.

Ive wanted a forge for quite some time, and though I could probably build a gas forge, there's something really nostalgic about coal that peaks my interest. I'm looking to build a variant of the brake drum forge, and needed a fan, so in light of this thread (which is where I got the real motivation for this) I'm building the blower fan first.

It's a 12" rotor which will likely have enough CFM at speed to keep a bounce house inflated.

My first attempt/ design used a full backing plate with 7 veins. This is before it warped miserably from welding (14ga)

So I chose to redesign mid way. The new design is an open paddle type fan. Still the same size and in the same shroud.

not sure why I chose 7 veins, I guess I wanted an odd number and 5 didn't look like enough.

And here is the rotor put together

i plan to drive the fan with an old bench grinder motor. The air intake would come around the motor to keep it cool(hopefully)

Frosty "T burner help

in Gas Forges

Posted

The one thing that’s obviously a wild card to me is your elevation. I’d be tempted to build a blown forge with a ribbon style burner if I lived that high up. That being said, I think you can still make a working forge, welding temps just might be really hard to reach.

Like frosty said, change only one thing at a time and take notes. The first thing I would try is opening the door/taking it off. Then observe the difference in flame character from where it was in the last pics. Go from there. You’re probably still going to want to seal up around the burner tubes.