-

Posts

170 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by bobasaurus

-

-

-

-

-

Thanks a lot Hans, I'm still a novice at welding and only intermediate at forging. What is a welding post? Using a regular grinding disc is a good idea to get the humps down first. Might give this a try.

Les, is a pipeliner disc just a slightly thicker cutoff disc that you can cut and grind with? Good idea on the weld speed, one problem is my little welder isn't rated for this thickness (should have preheated).

-

Any recommendations on how to clean up a weld like this? Maybe flap sanding disc on the angle grinder?

-

-

I forged this kitchen knife out of 5 layers of metal forge-welded together, using the “go mai” technique (my first attempt at it). The outer cladding is 15n20 steel (from an old sawmill bandsaw blade), the shiny line is nickel shim stock (scrap from my workplace), and the core that makes the cutting edge is 1080 steel. The blade is fully hardened and tempered to a hardness of about HRC 60. It has a full flat grind with a 25 deg cutting edge, and is acid etched to show the contrast of the nickel layer. My logo is electrolysis etched on the side, though it is subtle with the black finish.

The handle is made from cocobolo and has a piece of aluminum for the bolster. It has a hidden tang construction, pinned with brass rod. I’ve been refining this handle shape over a few previous knives and settled on this profile as my favorite. I finished the wood with several coats of amber dewaxed shellac, then a few lights coats of renaissance wax.

This was a gift for my coworker's retirement, gave it to him yesterday and he seemed quite happy. I was a bit nervous as they passed it around the room, as people don't realize just how sharp a knife can be.

Here are some progress pics of the build:

-

-

O1 also sparks weird... looks like mild steel.

-

-

Wow, how do you find that much coal in the wild? Did you have to dig it yourself?

-

These are beautiful, well done. What heat treatment do you use to prevent them from breaking on a lathe catch?

-

On 10/13/2019 at 5:08 AM, pnut said:

. I used to have a friend who had a prop business in North Hollywood. I never knew what I might see when I'd stop by. It was one of my favorite places to visit. I sold quite a bit to him also. Good find. Any time a prop business is selling it's inventory it's worth a look.

It was a crazy place to wander around, here are some pics of the inside. That same day I went to the sawmill and bought some nice pieces of hardwood (two maple legs, a maple stretcher, and a russian olive top) to make a side table for my bed. I'll have to think about forging some hardware for it.

-

So today I found a flatter in what must be the least likely possible location... a prop warehouse having a going out of business sale. It was part of the mining display props. Bought it for $20, thought it was a great find (been wanting one for years). They had welded a tab to it for positioning or something, should be easy to break/cut-off and reface. It was surrounded by giant tiki heads, mummies, pirate ships, leprechaun gold, and all sorts of miscellaneous bizarre crap.

-

Amazing work on that railing, wow.

-

Here are two recent projects. The dragon was a collaboration with my father, who made the amazing copper wings with his chasing and repousse skills. It was originally meant as a coat hanger, but now I might make it a decorative piece. I made the hammer for his Father's Day gift, it's a jewelers planishing hammer made from O1 and moradillo with a design copied from the talented Saign Charlestein

-

Regular wire brushes are pretty weak, their thin flimsy bristles don't do a lot of heavy scale removal and smoothing compared to a block brush. Block brushes have wide flat high-carbon bristles that scrape hot steel smooth.

-

Eventlessbox, that's a great-looking anvil and mounting job. Might want to forge the ends of those rods into something less pointy, though.

-

-

There are adzes setup both ways, but typically an outside bevel (outcannel) is desirable as it allows for better control of the bowl wall curvature (you can adjust the angle of the adze and it will follow the bevel in a swooping cut).

-

I recently completed this pair of bowl adzes. Mild steel bodies with forge-welded high-carbon edges. One has a low layer 1080/15n20 pattern-welded edge and a moradillo handle. The other has an old file as the edge and an apple handle. Finished with Tried & True Varnish Oil.

The moradillo one is headed to the Richard Arnold Charity Auction in the UK as a donation. I'm keeping the other.

-

-

-

Wow, that's a great fireplace screen.

I made this crazy-looking jig today. It's roughly copied from one I saw in a Black Bear Forge video about forging a dragon head. It allows the head to be supported in the vise and be supported from below (at an angle) while chiseling the facial features. Hopefully it works, may have to reinforce the top lip. I used random stuff around the shop instead of buying the proper materials, but it was fun to practice welding.

Jewelers Blocking Hammer

in Hand Hammers

Posted

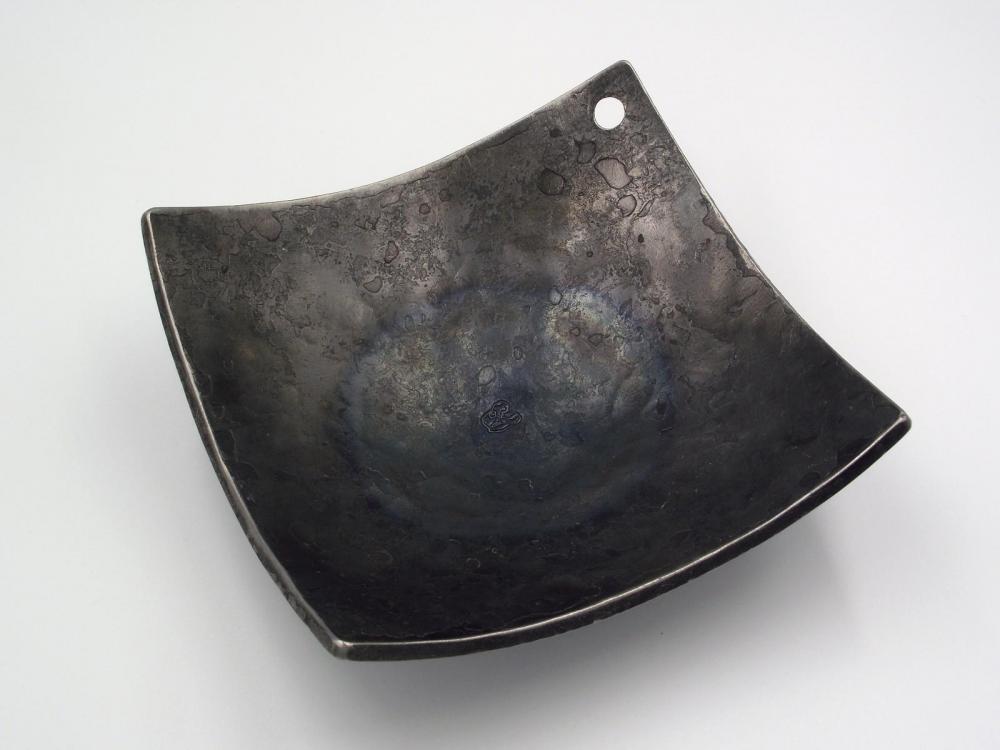

I made this as a gift for my father, it's a hammer used for shaping shallow bowls/dishes out of sheet metal in jewelry work. O1 head, Tasmanian blackwood handle.