BryanL

Members-

Posts

95 -

Joined

-

Last visited

Profile Information

-

Location

South Eastern CT

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Champion No. 0 back to work

BryanL replied to BryanL's topic in Power Hammers, Treadle Hammers, Olivers

Hi Paul, It was suggested to me recently to try machining the flat belt pulley from wood. Apparently that wasn't uncommon back in line shaft shops. I am now planning to that as it will be quicker and easier as I am more familiar with wood turning. I have a correction too, the original rpm on the Champion No. 0 was 400 not 200 as I wrote above. I will adjust for that. I should have a chance over the holidays to make strides getting the hammer running. Bryan -

Bear with me for a story. My phone halfway broke a couple weeks ago so I went looking for a T-Mobile store. The map said there was one close by, but when I got there, no store. The next closest was another half hour away so I stopped in the Sprint store across the street even though I'm not their customer. The lady there was super helpful and immediately spotted the anvil on my NEB shirt. Turns out her fiance is a self taught knifemaker. She fixes my phone over the next 2 hours, during which her fiance shows up and we talk shop about forging. Turns out his anvil got stolen along with other tools and stock by a guy on his way back to prison. I am going to sell him the anvil I recently brought home at a good rate in gratitude for his fiance's help. Then he dropped off this interesting stock at my house today just because he knows I'm in a temporary house/shop and don't have much with me. The 2 by 2 square is 4140. Just reinforces my impression that the blacksmithing community has overall been a very good one so far.

-

Champion No. 0 back to work

BryanL replied to BryanL's topic in Power Hammers, Treadle Hammers, Olivers

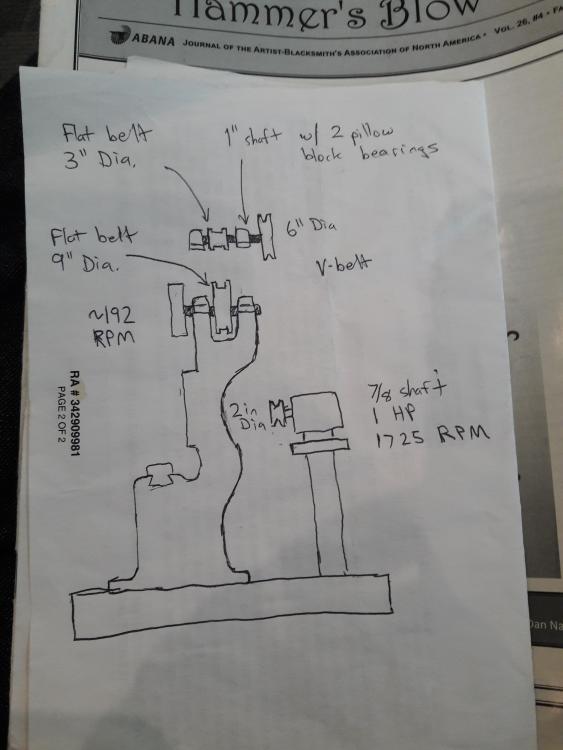

My latest musing on the hammer is all about the power transmission. I am sitting in the airport delayed so I sketched it all out. I have the motor, secondary shaft and pillow blocks. Now I need to scrounge the V belt pulleys and make the flat belt pulley. Good thing I just acquired an old Dalton metal lathe, now I need to learn to use it by making a flat belt pulley. Bryan -

Yeah I think it will be a great addition to the shop, especially for light twisting or filing work.

-

Other pics. The guy I got it from seemed to think it was for leather work, and the shape on the horizontal jaws were used for making the horn on a saddle. That would make sense, the linkages on the shear hardly seem strong enough for metal shearing.

-

Hello All, just scored a very interesting piece that has two pairs of vise jaws and a shear all operated by one treadle. The treadle also locks if you shift it over to the side. It should be very handy in the shop for light work but I've never seen anything like it. Does anyone have any idea who made it?

-

Well I got the bolt out by tapping on it with a chunk of wood to take the hit. Wire brushed most of it and coated with BLO. Few pieces left to clean up next time. Bryan

-

Same guy who I got the post vice and anvil from last weekend had me over to pick through his shop again this weekend. Got a trunk full of goodies. Wilton Vise, bolt cutters, 2 ball peen hammers, 2 Axe Heads, a chisel, set of sockets with socket wrench, Columbian forsner drill bits, complete set of drill bits, blacksmith puzzle, 500 pound hoist, 550 pound come along, and a baby anvil. All for $120.

-

Hello All, Just picked up a 5 inch jaw post vice last weekend that was frozen but all parts there. Got it moving fairly quickly but it's still very stiff and difficult to open and close. Decided tok break it down, strip the flaking paint and make it look nice while getting better movement. Pic as received and progress on cleanup. One question. The lower pivot bolt is being stubborn about removal. I have never removed one, so am hesitant tok get aggressive on it. Anyone have a thought on It? Oh! Also I discovered a maker's Mark! I was excited because I have never seen one on a post vice before. Looks like "Original Trenton" maybe...

-

What did you do in the shop today?

BryanL replied to Mark Ling's topic in Blacksmithing, General Discussion

I find after moving back a page, hit reload and it will come up. -

Elemental metal creations, What is that squat vice for? Looks like holding pipe or rod maybe? I saw on of those today but wasn't sure if I should get it or not. But I did bring home an anvil and post vice. Can anyone ID the anvil? It has a hardened plate on top, a "C" stamped on one side and a "M" stamped on the other side.

-

What did you do in the shop today?

BryanL replied to Mark Ling's topic in Blacksmithing, General Discussion

I made it to a hammer-in last weekend and met a guy who makes hammers. Went to his shop the next day and got to do a lot of firsts for me. I was a striker (to help make me a hammer), while annealing the hammer he showed me how to forge weld a pattern welded billet, and I got to use a power hammer to draw it out after welding. What a great day! -

What did one snowman say to the other snowman? Do you smell carrots?

-

Champion No. 0 back to work

BryanL replied to BryanL's topic in Power Hammers, Treadle Hammers, Olivers

Put the hammer back together as far as possible before I leave for 3 months for work. Hopefully I can make progress ordering or getting fabricated components while I'm away. Any thoughts on what the toggle arms should be made from? Carbon steel or tool steel? I'm leaning towards carbon but have no experience. -

Champion No. 0 back to work

BryanL replied to BryanL's topic in Power Hammers, Treadle Hammers, Olivers

Yeah I'm in love with the colors. But every time I turn around there is some other piece that needs paint. Somehow I can't get it all at once lol.